IECEx ATEX Certified Explosion proof LED Lights - Zone 1 Zone 2 Hazardous Area Lighting

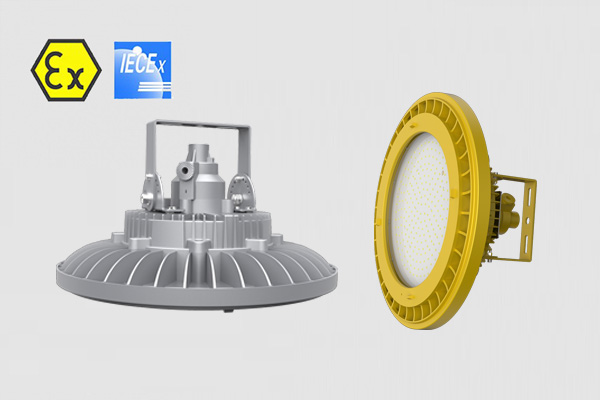

For Zone 1 Zone 2, Zone 21 Zone 22 hazardous area led lighting, 20W - 200W, 130lm/W,aluminum alloy + 8mm tempered glass, multi-installation for different projects, such as light tower, canopy light, marine grade.

Flameproof enclosure, Ex db op is IIC T6 Gb, Zone 1 & Zone 21 with explosive gas atmosphere, Zone 21 and Zone22 with explosive dust atmosphere, 10mm temered glass, 7J impact resistance,up to 26000lm.

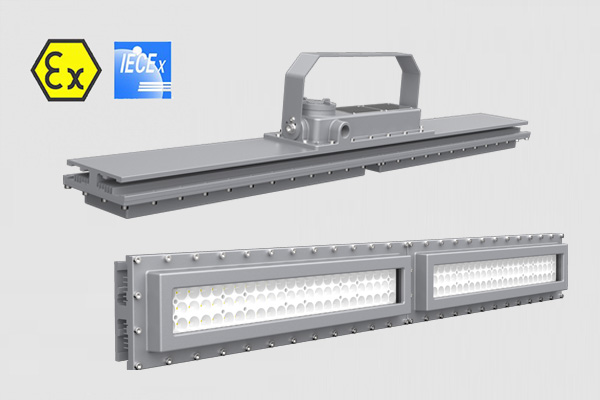

Flameproof enclosure, Ex db op is IIC T6 Gb, IP68 protection grade, tempered glass 10mm, withstand impacts up to 10J, 2 foot and 4 foot Length, 50Watt- 240Watt, 130lm/W light efficacy.

Zone 1 & Zone 21, 1ft, 2ft, 3ft, 4ft length can be selected, replace the traditional explosion-proof three-proof lamp, explosion-proof fluorescent tube, anti-corrosion, anti-glare, anti-drop, competitive price.

Flameproof LED hand lamp for Zone 1 & Zone 21 hazardous areas, 10mm tempered glass, pass the multi-angle drop test, 10W, 20W, 30W Power, can be connected to the cable, emergency power box.

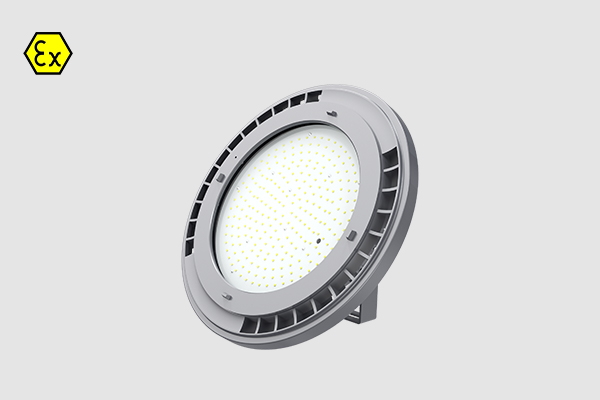

The CES-EX-SF series explosion-proof ceiling lamp has a strong shell, with features such as impact resistance, vibration resistance, and corrosion resistance. It can be used in hazardous environments of Zone 1&21, Zone 2&22.

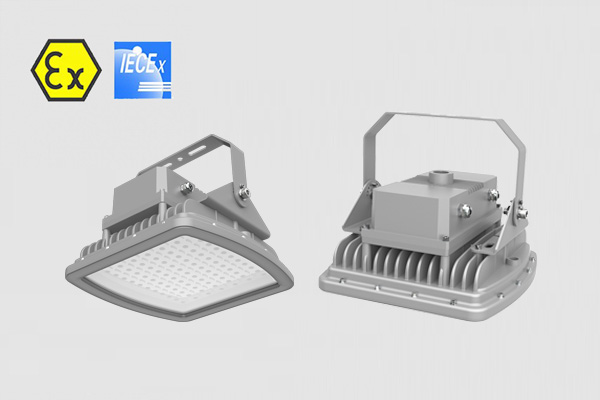

CES-EX-JX Series is your go-to solution for illuminating hazardous Zone 1 and Zone 21 areas. With ATEX approval, these Explosion-proof LED Flood Lights offer unbeatable safety standards.

Discover the pinnacle of safety and illumination with our CES-EX-GBX Series Explosion-proof LED High Bay Lights. Designed for hazardous Zone 1 and Zone 21 areas, these lights boast ATEX approval, ensuring the highest safety standards.

GB-02 explosion-proof lights are made of alloy aluminum and tempered glass, with shock resistance and anti-vibration performance. The luminaires have passed the ATEX IECEx standards test, from 30W to 80W for hazardous area lighting.

LN-02 explosion-proof lights obtained an IECEx ATEX certificate, it's safe for the Zone 1 and Zone 2 hazardous locations. The copper-free aluminum alloy body is powder-coated to increase durability and beautiful appearance, are able to withstand violent shaking and shock resistance.

an innovative line of LED hazardous area lighting products, specifically designed for use in potentially explosive atmospheres (Zone 1/21 & 2/22) within harsh industrial settings such as coal mines and oil & gas facilities.

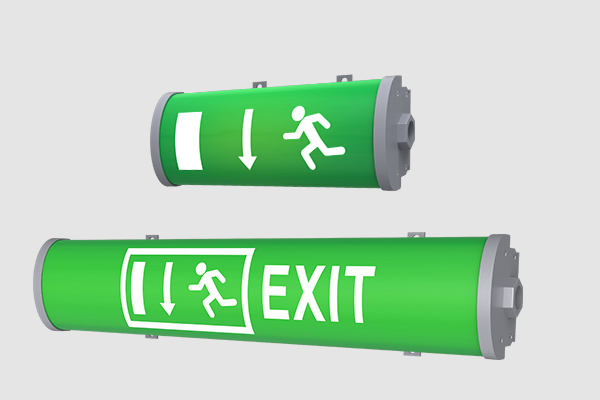

Explosion-proof safety exit lamps are for personnel evacuation, and fire operations to provide lighting fire emergency lamps! It usually uses an external power supply, when the power automatically switches to the battery power state!

Top 10 Explosion Proof Light Manufacturers Of China

The top 10 explosion-proof lighting manufacturers in China are recommended here.

Note: The name listing is given for person evaluation and is for reference only.

WAROM

Listed company, strong strength, is China's oldest explosion-proof equipment, explosion proof lights manufacturer, complete product line.

Mainly engaged in explosion-proof electrical equipment, professional lighting research and development, production and sales. On May 24, 2017, the company was successfully listed on the A-share market of Shanghai Stock Exchange (stock abbreviation: Huarong Stock, stock code: 603855).

The company's management is fully in line with the international advanced level, taking the lead in passing the certification of IS09001 quality management system, ISO14001 environmental management system, ISO10012 measurement management system and OHSAS18001 occupational health and safety management system. At the same time, the United States FM/UL, ATEX, IECEx, Russia CU TR, Brazil INMETRO certification and other international quality standard certification.

As the oldest explosion-proof brand in China, Warom entered the international market very early, with subsidiaries in different countries and enjoys popularity.

KING OCEAN

Ocean King was established in August 1995. It is a company that independently develops, produces and sells various professional lighting equipment, lighting (including explosion-proof lamps) + intelligent control systems, service products, and undertakes various lighting engineering projects. Private joint-stock high-tech enterprise, listed on the small and medium-sized board of Shenzhen Stock Exchange on November 4, 2014, the company has more than 3,000 employees, serving electric power, metallurgy, railway, oil field, petrochemical, public security, fire protection, coal, military, venues, ships, etc. Large and medium-sized state-owned enterprises and institutions. Ocean King is committed to providing customers with humanized professional lighting solutions, and strives to become the best service company for professional lighting in the world.

Explosion-proof lamps manufacturer, mainly active in China, mainly in traditional (non-LED) explosion-proof lamps. Traditional lamps are ATEX and IECEX certified.

NJZ

Founded in 2012, NJZ Lighting is a technology-leading manufacturer, driving the most innovation and durable portfolio of industrial lighting products for Hazardous location, General industry and Marine applications.

a full line of globally certified explosion proof lighting fixtures to deliver a professional and durable lighting solutions for the application where there is potential risk such as combustible gas or dust. NJZ products and manufacturing system are both approved and certified by the UL and TUV organization according UL844 and IECEX 60079.

CESP

SHENZHEN CESP CO.,LTD, Founded in 2007, Committed to providing high-quality patented products in the military and industrial fields, CESP is top explosion-proof lamp OEM and ODM manufacturer and supplier from China, and the first UL and CUL certified hazardous location LED lighting company in China.

CESP explosion-proof lighting products are all patented products of proprietary mould, and have obtained UL844 North American explosion-proof certificate, ATEX explosion-proof certificate, IECEx explosion-proof certificate, and most products have also obtained UL1598A coastal defense anti-corrosion certificate.

In addition, in December 2020, CESP launched a Class 1 Division 1 explosion-proof hand lamp, which was issued by the CSA Group.

KHJ

Shenzhen KHJ Semiconductor Lighting Co., Ltd. was established in 2009, the company is a collection of research and development, production, sales in one of the enterprises.

Products include explosion-proof lighting, explosion-proof electrical appliances, industrial lighting, commercial lighting four major divisions, respectively committed to the security field, industrial field, commercial field and special light source field of the lamp product research and development, production and sales. Since its establishment in 2009, the product variety has gradually developed from a single light source into four major divisions. The scope of the market has also expanded from a single commercial field to industrial and security fields.

SNC

Founded in 2012, SN has been committed to the research and development, production and sales of LED lighting products. It is a powerful high-tech manufacturer. It has successively passed a series of quality, environmental management system and enterprise intellectual property management system certifications such as ISO9001:2015 and ISO14001:2015.

In recent years, SNC has developed explosion-proof floodlights, explosion-proof high Bay, explosion-proof line lights, and obtained the North America explosion-proof certificate, rapidly occupying the North American market.

In addition, SNC is also developing other special lighting products, such as livestock lighting, poultrylighting, grow lighting, intelligent lighting, etc.

PAN MEI (James, Venas)

Dongguan Pan Mei electronics Co., Ltd. is a professional, comprehensive and global manufacturer of LED lighting, explosion-proof lighting and explosion-proof electrical appliances.

Product roadmap are LED commercial lighting, led industrial lighting, UV lamp, plant lamp, industrial explosion-proof lamp, industrial explosion-proof electrical appliances and other fields.

Pan Mei focuses on providing industrial lighting and commercial lighting. After long-term efforts, PanMei electronics has obtained UL, CQC, IECEx, ul844, ATEX, ABS, EAC, NOM certification for different types of industrial lighting products.

Pan Mei is become a lighting brand in North America and Europe and have a local customer service team in North America and Europe to provide 24-hour delivery service.

OUHUI

Jiangsu Ouhui Lighting Co., Ltd. is a high-tech enterprise engaged in explosion-proof lamps, electrical appliances, professional lighting products, emergency lighting lamps research and development, production and manufacturing, sales and service in one, with a professional R & D team, advanced testing and production equipment, excellent and reliable sales and after-sales service personnel. The company has strong technical force, in the optical, electronic, electrical and other professional fields, with process engineers, structural engineers, quality engineers, R & D engineers and other high, intermediate technical personnel.

Ouhui has risen rapidly in recent years, mainly with ATEX type explosion-proof lamps.

CARY

Shenzhen CARY is located in the forefront of LED technology in China - Shenzhen. Is a 15 years engaged in industrial and outdoor lighting research and development, integrated lighting design, marketing, service high-tech enterprises.

The products are widely used in power generation, substation, high-speed railway construction, oil exploitation, refining, mining, shipyard, automobile factory and other fields.

CARY's products have passed CE, ROHS, ATEX, UL844, ETL, DLC and other certifications. With experienced R & D team, exquisite technology, scientific management system, excellent quality and efficient service, Cary has market share in China, North America, Europe, Russia, the Middle East and North Africa.

TORMIN

Zhejiang Tormin is a national high-tech enterprise specializing in the research and development, production and sales of industrial lighting fixtures. Products are widely used in petroleum, chemical, electric power, mining, metallurgy and other industrial enterprises lighting, China's national high-tech enterprises ", "National Torch program", the company has passed the ISO9001 quality, ISO14001 environment, OHSAS18001 occupational health and safety management system certification, The products have passed the national coal mine safety certification, the National Lamps and Lanterns Quality Supervision and Inspection Center and the National explosion-proof electrical Products Quality Supervision and inspection Center and other domestic authority certification, in China, Tongming explosion-proof lamps and explosion-proof electrical appliances are used in many projects.

For the international market, Tormin explosion-proof lamp is mainly European ATEX explosion-proof certification, IECEx international explosion-proof certification.

Portable Explosion Proof Lamp 20W 30W 40W

LED EXPLOSION-PROOF PORTABLE LIGHTS

Model No. CES-J20/J30/J40S

These explosion-proof portable flood lights are ideal for hazardous areas lighting such as accident scenes, chemical spaces, inspections, and more unplugged lighting. The luminaries obtained ATEX and IECEx certificates, which can apply to Zone 1 and Zone 21 hazardous locations with explosive gas and dust atmospheres.

10-meter cord, or with the battery backup, this explosion-proof portable light can work continuously for 3 hours.

20W, 30W, and 40W POWER can be optional.

• Wastewater treatment, oil, and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor walls, and stanchion-mounted general area lighting, where flammable vapors and gases are present.

• Applies to hazardous locations of Zone 1 Zone 21 with explosive gas atmosphere.

Features

- Light efficacy: 130lm/W

- -40°C to +55°C ambient operating temperature

- Housing – Aluminum alloy (ADC12 )

- Lens – tempered glass

- Beam angle: 90° / 120°

- Power Driver: High-Efficiency LED Driver

Parameters

- Power: 20W / 30W / 40W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- Working Time: 3 hours for emergency

Ex-proof Standard

NEC and CEC standards for hazardous locations and environments

-

ATEX:

- EX II 2G Ex eb mb op is IIC T4 Gb

- EX II 2D Ex op is tb IIIC T95°C Db

- IP66

- Certify No.:IEP 19ATEX 0714

IECEx:

- Ex ec IIC T4 Gc

- IP66

- Certify No: IECEx UL 18.0046

Mounting

Versatile mounting options:

- Portable bracket

Shipping Container Lighting - 2ft Explosion Proof Light - Mexico

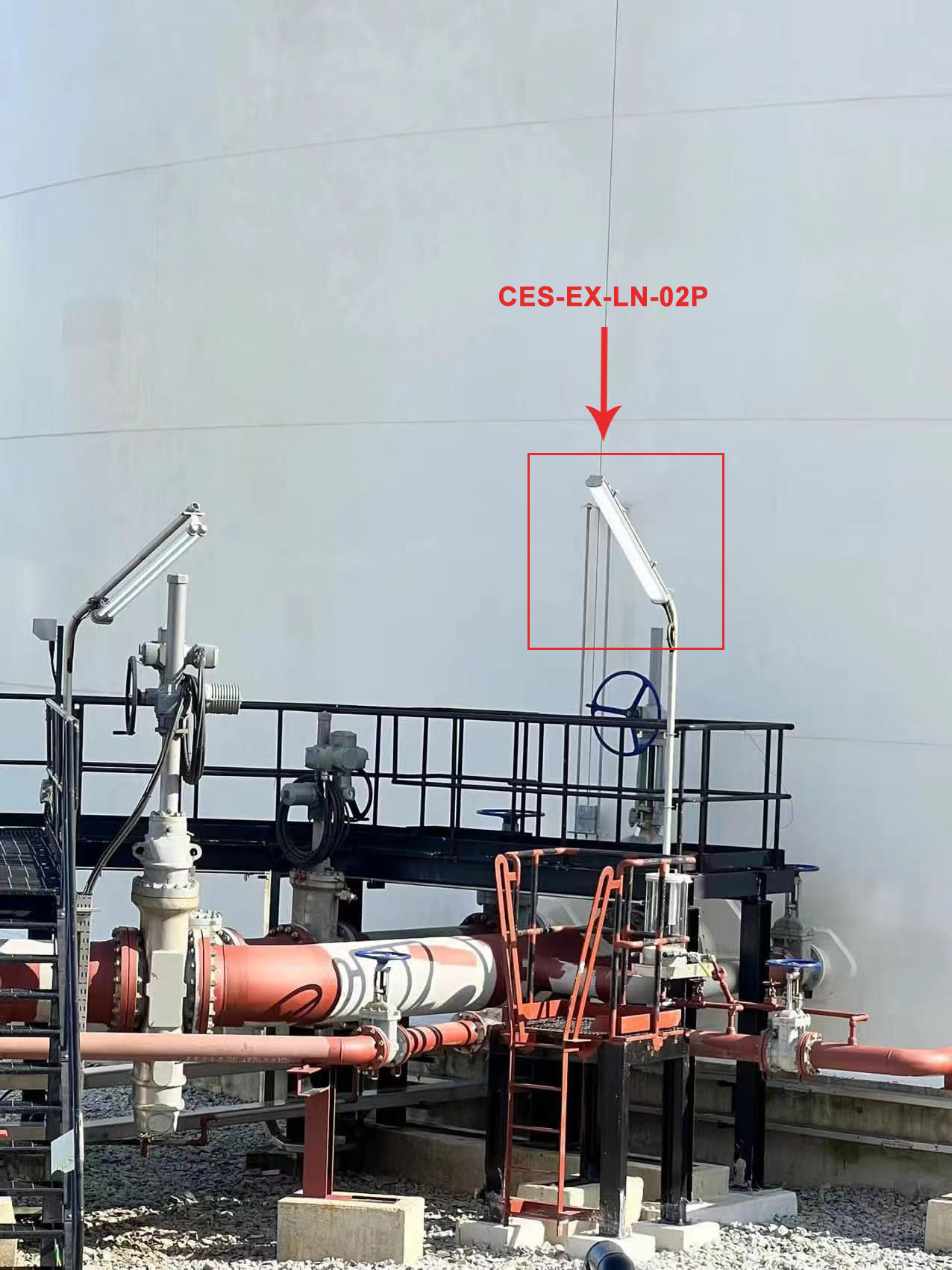

Luminaires: CES-EX-LN-02P

2ft explosion proof linear light used for the shipping container.

For the project, a total of 12 containers, with 6 lamps installed in each container.

If you would like to know more, please contact us any time.

20W Explosion Proof Exit Lighting - Zone 1 Zone 21 - Voltage 100V-277V

This Explosion Proof emergency lighting is designed for Zone 1, Zone 21 hazardous locations as the exit sign, it is available as an AC (100V - 277V) version.

Applications: In harsh and hazardous environments where illuminated exit signs are required.

ATEX: EN IEC 60079-0-2018; EN 60079-7-2015; EN 60079-18-2015; EN 60079-31-2014;

IECEx: IEC 60079-0-2017; IEC 60079-7-2015; IEC 60079-18-2014; IEC 60079-31-2013;

IECEx & ATEX :

- “CAUTION-USEFASTENER WITH YIELD STRESS ≥ 640 MPa”;

- “WARNING – DO NOT OPEN WHEN ENERGIZED”;

- “WARNING – DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT”;

- “WARNING – ONLY USE CABLES SUITABLE FOR 85°C”;

- " WARNING - DETAILED TEMPERATURE CLASS - SEE INSTRUCTIONS”;

- “THE FLAMPROOF JOINTS ARE NOT INTENDED TO BE REPAIRED”;

- End user shall use certified cable gland or conduit with suitable type of protection for final installation purpose;

- External earthing wire shall be connected when used and the cross-sectional areashall be more than 4mm2 or 10AWG;

- Under rating condition, maximum temperature on the luminaire’s shell shall not be higher than 130℃ for T4.Temperature at cable inlet shall not be higher than allowable limit of the cable applied, to ensure the cable operation normally. The branch point is 83.6℃ and cable entry point is 69.4℃.

Features

- Industry-leading efficacy: up to 120lm/W±5

- -40°C to +45°C /50°C /55°CAmbient operating temperature

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: M25Χ1.5 or NPT 3/4”-14

- Material : Aluminum alloy (ADC12 ) + PC

Parameters

- Power: 20W

- Voltage: AC100-277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 2400LM

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: High efficiency driver

- Dimension: 329 mm x 125mm x 88.7 mm

- Weight: 2.5KG (1 Foot)

Certificate & Standard

Have certified CES-EX-LN-02P fixtures with the IECEX and ATEX standards for hazardous location and environments.

ATEX:

- II 2G Ex eb mb IIC T5…T6 Gb

- II 2D Ex tb IIIC T**°C

- IP66

- Certificate No:SEV 21 ATEX 0578 X

IECEx:

-

• Ex eb mb IIC T5…T6 Gb;

• Ex tb IIIC T**°C;

• IP66

• Certificate No:IECEx SEV 21.0038X

Amounting

Versatile mounting options:

- Wall Ceiling mounting

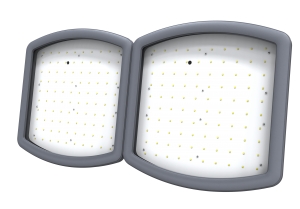

CES-EX-LN-02P Explosion Proof Linear Light

EX-proof Fluorescent lamp VS CESP Ex-proof linear luminaries.

CNOOC - Oilfield & Offshore Lighting Engineering Project

This lighting project is for CNOOC in China. The luminaries including below,

CES-EX-LN-40P Explosion proof LED linear Light

CES-FG-02-120 Explosion proof LED Floodlight

CES-HB5-200 Explosion proof LED High Bay

Explosion Proof Flood Light - Class 1 Division 2 - 240W/300W/370W

Applications:

• Wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting, and where flammable vapors, gases are present.

• Applies to hazardous locations of Class I, Division 2 with explosive gas atmosphere.

• Applies to marine locations, non-recessed outside type (salt water).

Warning:

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING 40°C;

- FOR SUPPLY CONNECTION, USE WIRES RATED FOR AT LEAST90°C;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

UL for marine locations:

- OUTSIDE TYPE or OUTSIDE TYPE (SALT WATER);

Features

- Industry-leading efficacy: 120 - 140LM/W

- -40°C to +55°C Ambient operating temperature

- Wide optics for uniform illumination

- Entry Size: NPT 3/4”-14 ;

- Housing –Aluminum alloy (ADC12 );

- Lens –tempered glass

- Beam angle: 108°, 120°

- Dimension: 400x400x169mm

- Weight: 22kg

Parameters

- Power: 240W / 300W / 370W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: Meanwell HLG series

Certificate & Standard

Have certified CES-J fixtures with the NEC and CEC standards for hazardous location and environments

- Class I, Division 2, Groups A, B, C and D

- T-Class: T5

- Damp and wet locations

- Certificate No:E475887

- US: UL 844; UL 1598A;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0;

Mounting

Versatile mounting options:

- Universal installation

- Mounting Angle:0°to ±90°;

Explosion-proof cable gland types

Explosion-proof sealing connector are also called explosion-proof cable glands, which are used for tightening and sealing of cables of explosion-proof equipment.

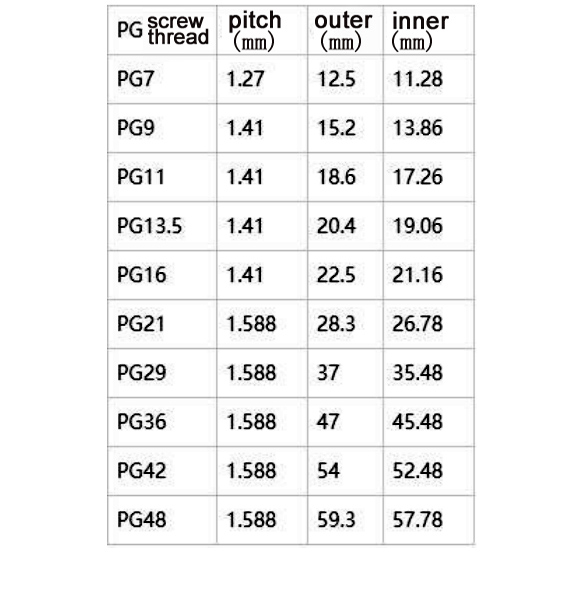

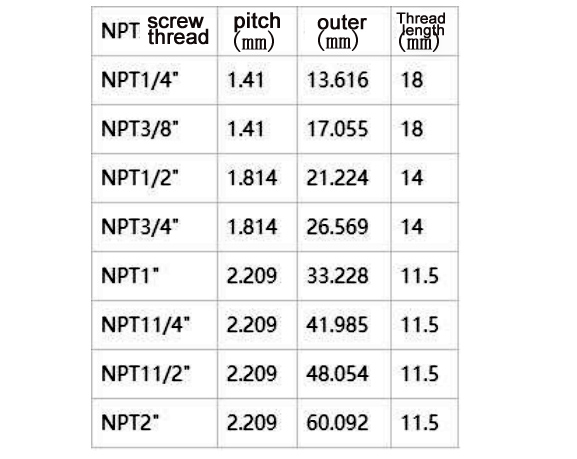

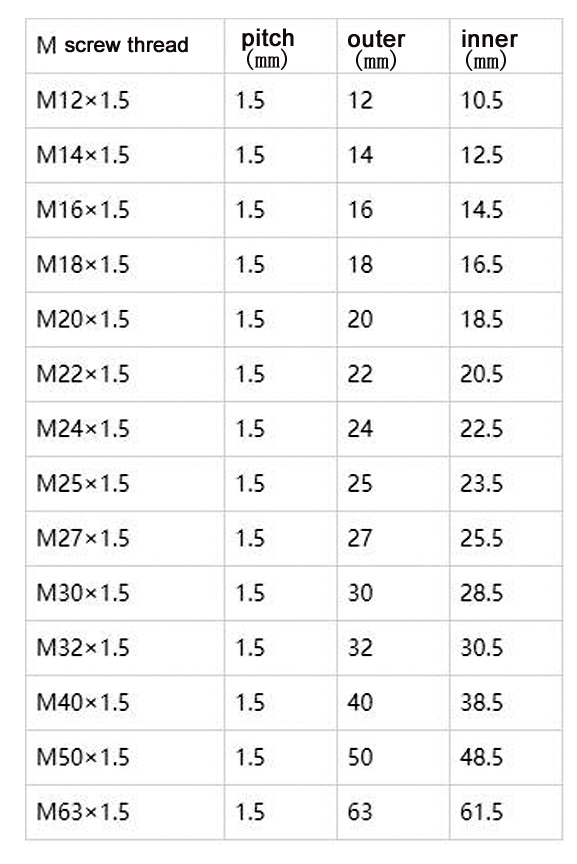

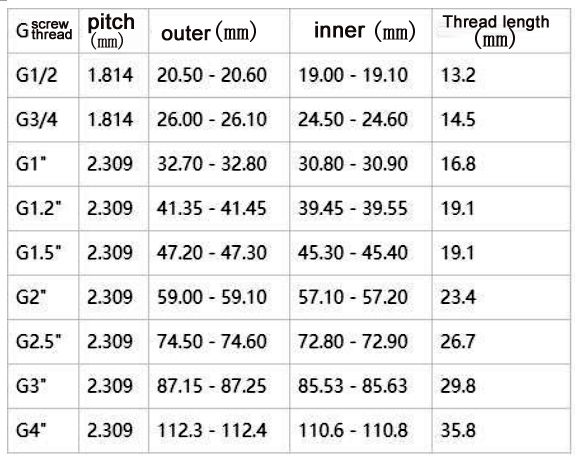

Thread specifications are divided into the following four types:

Metric M thread, German PG thread, American NPT taper thread, Imperial G(PF) pipe thread

The most common demand is M thread. Among the specifications, M12, M20, M25, M32, M63, M72, M75, etc., the common pitch is 1.5 and 2.

There are also some threads that are not conventional and need to be customized, such as reducing-diameter explosion-proof cable glands. The specifications at both ends are customized according to the interface specifications of the introduction device of the explosion-proof equipment on site.

For unconfirmed specifications and sizes that need to be purchased, you should confirm with the seller, because generally non-standard customized specifications of explosion-proof cable glands cannot be returned after sale, so if the purchase quantity is large, it is best to order samples to confirm that they are correct, and then place bulk orders.

The product is generally made of S304 stainless steel, with unique explosion-proof function, special design of clamping melon and clamping ring, large clamping cable range, strong tensile strength, waterproof, dustproof, salt resistance, weak acid resistance, Alcohol, oil, fat and general solvents.

The following is the size comparison table of inch thread (G), metric thread (M), American thread (NPT) and German thread (PG)

CESP provides customized explosion proof cable glands of 316 stainless steel, high temperature resistant, flame retardant, etc. Protection level: within the specified bayonet range, and use the sealing ring to tighten the tightening head to reach IP68-5 Bar.

Welcome to contact us!

How to design the retricted breathing lamps (ex-proof “nR”)

Restricted breathing lamps are a kind of "n" type explosion-proof products. They are used in enviroment with potentially explosive gas atmospheres in Zone 2. They are the same as increased safety lamps in terms of use, but their light source types are higher than that of increased safety lamps. The weight is lighter than that of flameproof lamps, but the scope of use is not as wide as that of flameproof lamps. It has the characteristics of light weight and various types of applicable light sources. It is undoubtedly an economical and easy-to-use product for use in places where good lighting is required in zone 2.

According to IEC/EN 60079-15 Type of Protection “ n ”

Electrical installations designed so that ignition is unlikely to occur in normal or abnormal operation. The gas explodes. The main protection methods are classified as follows.

- nA: Non-Sparking

- nC: Enclosed-Break (blocked), Hermetically-Sealed (metallicor glass tight seal), Non-Incendive (non-incendive), Sealed device (sealed)

- nR: Restricted Breathing Enclosure

This new type of product has many novelties in explosion-proof mechanism, characteristics, inspection difficulties and design. Only when designers and users understand these can they be well designed and used.

Part.1 Explosion-proof mechanism for the Restricted breathing lamps

To understand the explosion-proof mechanism of the restrictive breathing lamp, we must first understand where it is used, and understand where to start with this product to consider the explosion-proof structure treatment.

Restricted breathing lamps have certain restrictions on the use of this kind of lamp, which is only allowed to be used in places with potential explosion hazard gas environment 2, that is to say, the place where this lamp is used is relatively less dangerous. In normal operation, there are no explosive hazardous substances in the environment, including gases, vapors and mist, and dangerous explosive gases, vapors or mist will appear only when they fail, and the chance of such failure is very small, and even if there is a failure, the time of failure is very short. It is precisely because of the particularity of the use environment that this kind of lamp only needs to prevent the danger of dangerous substances in rare cases and the duration of dangerous substances is extremely short. Therefore, the shell of this kind of lamp is to limit the amount of gas, vapor and mist entering, rather than preventing gas, vapor and mist from entering.

When the lamp is working normally, the calorific value of the internal light source is relatively high, which will cause the internal gas to expand and form a positive pressure in the light source cavity of the lamp. Due to the formation of positive pressure, the internal gas leaks out. When the lamp is out of use, the inside of the lamp will gradually cool down. At this time, due to the temperature drop in the lamp, the gas volume is reduced. At this time, the air volume in the lamp is smaller than that in the initial state of the lamp, which causes the inside of the lamp. of negative pressure. If the lamp does not take protective measures, and an accident happens at this time, there is a leakage of dangerous substances, then the dangerous substances may enter the lamp. When the lamp is used again, the high temperature inside the lamp may ignite the explosive gas, vapor or mist existing in the lamp, resulting in a dangerous accident. Restricted breathing lamps are based on this characteristic of lamps, and the light source and its related electrical components are put into restricted breathing enclosures. A restricted breathing enclosure is a type of enclosure that restricts the entry of gases, vapors and mists. That is to say, a restricted-breathing luminaire is a luminaire product with a special housing. This product increases the ability of the housing to restrict the ingress of gases, vapors and mists, so hazardous substances do not enter the luminaire for a short period of time. Of course, if the accident lasts for a long time, there will be danger. Therefore, for this kind of lamps, corresponding measures have been taken to further increase the safety. First of all, its use place is limited, and it is only allowed to be used in Zone 2, so that due to the short maintenance time of the accident, the number of accidents is less, and the chance of danger is reduced. At the same time, strict performance inspections have been carried out for the dangerous components in the casing, such as ballasts, lamp sockets, starters, etc., to ensure the safety and reliability of the components. In this way, this explosion-proof lamp is safe.

Before the emergence of restricted breathing lamps, there were two commonly used lamps in the explosion-proof lamps family: explosion-proof lamps and increased safety lamps. Explosion-proof lamps can be used in areas with potentially explosive gas atmospheres in Zone 1. This kind of lamp mainly uses the high strength and explosion-proof property of the product shell to achieve the purpose of explosion-proof, allowing accidents in the surrounding environment and dangerous substances in the lamp. It uses the strength of the lamp shell to prevent the pressure generated by the internal explosion of the lamp from damaging the lamp body and ignites the surrounding environment, and at the same time uses the extremely small gap between the metal joints of the shell to prevent the flame in the lamp from igniting the surrounding flammable substances; Lamps are also a kind of explosion-proof lamps that are widely used. This kind of lamps is designed by adding a series of safety measures, such as increasing the electrical clearance and creepage distance, increasing the protection level of the shell, and using explosion-proof lamps where sparks may occur in the lamps. Measures to deal with, limit the temperature level of lamps, etc. to achieve safety purposes. In my country, most of this type of explosion-proof lamps are used in Zone 2, and only increased safety single-plug fluorescent lamps are allowed to be used in Zone 1.

Through the above description, it is not difficult to find that the restricted-breathing lamps achieve the purpose of explosion-proof by restricting the entry of explosive gas, vapor or mist into the interior of the lamp body through the good sealing of the shell; And high-strength shell to achieve the purpose of explosion-proof; increased safety lamps and lanterns by increasing the safety of the lamp itself to achieve the purpose of explosion-proof lamps. Therefore, these three lamps each have different characteristics.

Part.2 The Feature of the Restricted breathing lamps

Through the description of the explosion-proof principle of restricted-breathing lamps, it is not difficult to find that restricted-breathing lamps mainly improve the reliability of internal components, at the same time increase the protection capability of the shell, and limit their use places. This also determines its different characteristics from other explosion-proof lamps.

First of all, due to the requirements for limiting the protection capability of the internal components and shells of the breathing lamps, the restricted breathing lamps have higher requirements on the selection of internal components: they must be components with reliable performance and firm connections. After the components are selected, the main hazards of this kind of lamps are the limited breathing ability of the shell and the heating problem of the product surface. Therefore, the measurement of the surface temperature in the inspection is to select the surface of the lamp body, which is the same as the explosion-proof product, which also forms a great advantage compared with the increased safety lamps.

The increased safety lamp is to increase the safety of all parts of the lamp, including the temperature limit. Therefore, the temperature measurement of the increased safety lamp is to detect the high surface temperature of each component inside the lamp, so that when the increased safety lamp determines its temperature group The temperature is determined by measuring the high temperature points on the surface of the light source. Therefore, the heat generation of the increased-safety lamps is very high, and their applicable range is narrow. Those flammable gas environments with low ignition temperature are not suitable for the use of increased-safety lamps. It is precisely because the safety-enhancing lamps and lanterns are considering the safety of the internal components of the lamps and lanterns, which have certain restrictions on the use of light sources. In the national standard currently used in my country, only cold-start fluorescent lamps, incandescent lamps and self-ballasted fluorescent lamps are allowed. Light bulbs that ignite for a short time after being broken (verified that the short-term high temperature of the bulb does not cause danger). From the restrictions on the increased safety lamps, it is not difficult to find that the restricted breathing lamps and lanterns use the restricted breathing type casing, so when measuring the surface temperature of the lamp, the temperature of the outer surface of the lamp is measured. In this way, under the condition of good lighting design and good heat dissipation, it is easy to reduce the surface temperature of the lighting and broaden the use range of the lighting. While reducing the surface temperature of the lamps, the types of light sources used by the lamps are also increased. Since the housing is of a restricted breathing type, the interior of the luminaire is relatively safe, so most of the light sources can be used except for those light sources that are dangerous to the luminaire itself. Restricted breathing lamps can use incandescent, mercury, sodium and metal halide lamps as well as fluorescent lamps. In this way, the illuminance of the restricted breathing lamps is greatly increased. Some lamps that need high illumination and high heat generation hanging at the height of the workshop can completely use the restricted breathing lamps, because it is easy to form a zone 2 dangerous place at the height of the workshop.

Secondly, since the restricted breathing type luminaire only needs to have the restricted breathing capacity of the outer casing, it does not need to make the outer casing as thick as the flameproof type lamp, making the lamp very heavy. In this way, in some places that require high illuminance and low degree of danger, restricted breathing lamps can completely replace explosion-proof lamps, because they are lighter than explosion-proof lamps, but they can use the same light source and have the same temperature group. do not. Of course, it cannot be used in Zone 1 hazardous locations, and the scope of use is small, which is incomparable with explosion-proof lamps.

To sum up, the restricted breathing lamp has the characteristics of low external heat generation, wide applicable temperature range, relatively many types of light sources, and relatively light shell.

Part.3 Inspection Difficulties for the Restricted breathing lamps

From the explosion-proof principle and characteristics of restricted breathing lamps, it is not difficult to find the main problems in their inspection.

First of all, the restricted-breathing lamps have high requirements on the performance of the internal components, so the inspection of the internal components of the lamps in the inspection is quite cumbersome. Mainly focus on the inspection of ballasts, lamp sockets and starters. It is mainly the inspection of the ballast and the starter, including the high-voltage pulse test of the ballast and the performance inspection of the starter seat, which not only costs high test costs, but also takes a long time to test.

Secondly, it is a difficult point in the inspection that the enclosure of the restricted breathing luminaire restricts the breathing ability. For longer joints in luminaires, it is difficult to pass the test of the restricted breathing enclosure. Because during the test, it is required to evacuate the shell to -3

kPa, and then rely on the sealing performance of the shell itself so that it does not drop to 1.5kPa within 3min. This test has very strict requirements on sealing and requires very good elasticity of the gasket. In the large number of experiments we have conducted, not a single unit has passed the test at one time, and all of them are continuously improved in the experiment, so as to finalize the final product design.

Part.4 Some techniques that can be used in design of the Restricted breathing lamps

Through the above analysis, several suggestions are put forward for the design of restricted breathing lamps.

First, because of the reduction in the joint surface that restricts the breathing shell. The more surfaces a restricted breathing enclosure has, the more leak points it will have. Conversely, the fewer surfaces a restricted breathing enclosure has, the fewer leak points it will have, so that the chance of passing the restricted breathing enclosure test is better. bigger. Even if there is a leak, it is easy to identify the leak and remedy it.

Second, reduce the length of the joint surface. Due to the high degree of sealing required by the restricted breathing type housing, the longer the distance of a joint surface, the more leakage points. To seal, the sealing distance must be reduced, so that the number of fasteners will increase, which will be difficult to install and disassemble. Add trouble.

Finally, avoid the difficulty in testing. During the inspection, the inspection of some internal components is quite time-consuming; it will also cost a lot of inspection funds, and we can also try to avoid it in the design.

The following takes the restricted breathing lamps as an example to illustrate the design points of the restricted breathing lamps.

- Pay attention to the design of the lamp body, which can reduce the high surface temperature of the lamp. The metal part of the lamp should be as large as possible, and the light source should be wrapped in metal as much as possible. Using the principle of parabolic focus, the light should be reflected as much as possible through the lamp body. If there is a reflective umbrella, you can consider the reflective umbrella as close to the lamp body as possible. The body dissipates heat.

- In designing the bonding method between the transparent part and the lamp body, the adhesive structure should be considered. Because the joint surface between the transparent part and the lamp body is generally the long joint surface of the lamp, and the problem of rubber aging is easy to occur due to heat generation, it is not suitable to use rubber material for sealing. The surface temperature of the lamp body is a better sealing measure. In this way, this interface can be easily passed during the restricted breathing type enclosure test. However, when using the adhesive, it is necessary to consider the heat-resistant temperature of the adhesive and the damage to the transparent parts of the lamp due to different thermal expansion rates. Usually, the solution to the different thermal expansion rates of adhesives is to add additives of other materials to the sealant, so that the thermal expansion of the glass has a certain space without damage.

- Only the light source: wiring socket and lamp socket are installed in the restricted breathing housing, and the starter and ballast are treated with other explosion-proof measures, which can greatly reduce the production cost and inspection cost.

- The light source is taken out from the rear of the lamp body or from the side. This reduces the number of luminaire joints and the length of the joints. Lamps generally have three joint surfaces, the transparent part and the lamp cover, the lamp cover and the lamp body, and the lamp body and the junction box cover. Among them, the joint surface between the lamp cover and the lamp body is often used as the place to replace the light source, but this joint surface is relatively large. Due to the need for replacing the light source, the fasteners are not easy to be too many, which forms a contradiction and limits the breathing test. difficult to pass. If the light source is considered to be removed from the rear for replacement, the length of the joint will be greatly shortened, and the joint can be easily sealed with four fasteners. If you are afraid of the performance problem of the lamp caused by the high temperature of the lamp holder caused by taking out the light source from the rear, you can consider dividing the reflector of the lamp into two parts. The large part is fixed and will not be taken out when the light source is taken out; The part is movable and integrated with the lamp holder, when the light source is taken out, it is taken out with it. Its main function is to reflect the light hitting the lamp holder, so that the temperature of the lamp holder is lowered, and at the same time, the sealing material is placed in a low temperature place, which can well prevent the aging of the rubber material.

- The choice of sealing material: the sealing material used to seal the restricted breathing enclosure is difficult to choose, and some customers have to repeatedly select a better material when conducting experiments. Of course, high temperature resistance, aging resistance, good material elasticity and good recovery are the main conditions for material selection.

- The choice of sealing structure: the sealing structure adopted by most enterprises is usually face sealing. Rubber is sandwiched between the two planes, and this structure has great disadvantages. First of all, it is caused by poor plane processing. Due to poor plane processing, the flatness cannot meet the requirements. In places far from the fasteners, the sealing is often not tight due to uneven force; secondly, the installation hinges do not match. It causes the upper and lower hinges to struggle with each other, and it is not easy to press the gasket at the place where the hinge is installed, which is easy to cause leakage. At present, a better sealing method is to use wire sealing, and make a protrusion for wire sealing on one side of the joint surface, and then press it with a fastener. This kind of sealing effect is better.