IECEx ATEX Certified Explosion proof LED Lights - Zone 1 Zone 2 Hazardous Area Lighting

For Zone 1 Zone 2, Zone 21 Zone 22 hazardous area led lighting, 20W - 200W, 130lm/W,aluminum alloy + 8mm tempered glass, multi-installation for different projects, such as light tower, canopy light, marine grade.

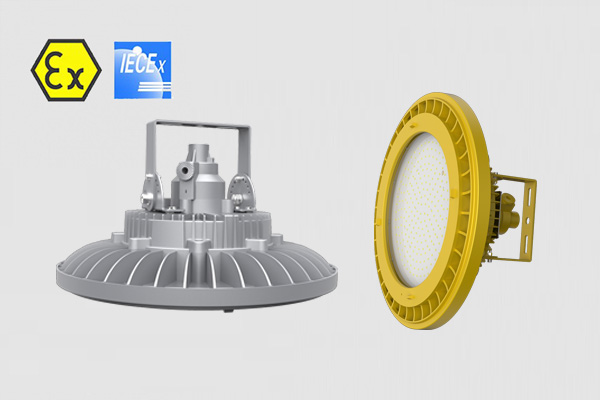

Flameproof enclosure, Ex db op is IIC T6 Gb, Zone 1 & Zone 21 with explosive gas atmosphere, Zone 21 and Zone22 with explosive dust atmosphere, 10mm temered glass, 7J impact resistance,up to 26000lm.

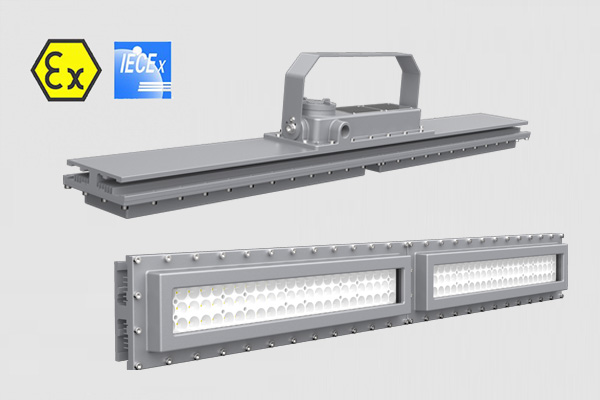

Flameproof enclosure, Ex db op is IIC T6 Gb, IP68 protection grade, tempered glass 10mm, withstand impacts up to 10J, 2 foot and 4 foot Length, 50Watt- 240Watt, 130lm/W light efficacy.

Zone 1 & Zone 21, 1ft, 2ft, 3ft, 4ft length can be selected, replace the traditional explosion-proof three-proof lamp, explosion-proof fluorescent tube, anti-corrosion, anti-glare, anti-drop, competitive price.

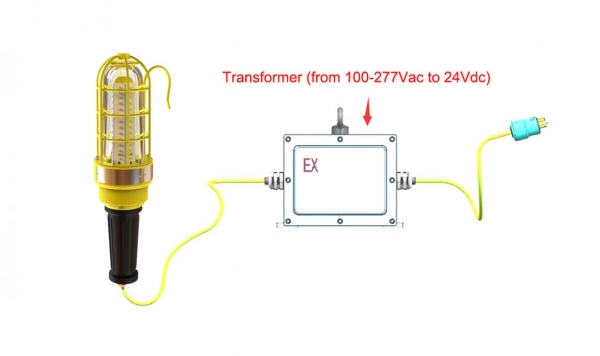

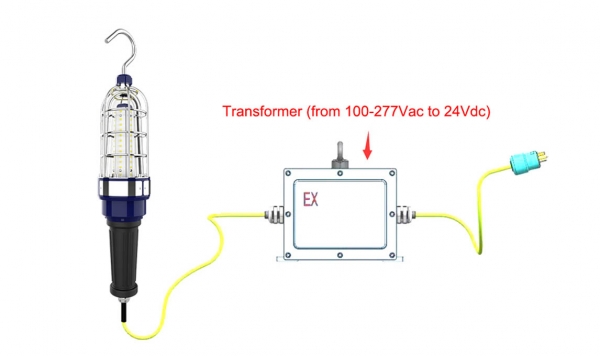

Flameproof LED hand lamp for Zone 1 & Zone 21 hazardous areas, 10mm tempered glass, pass the multi-angle drop test, 10W, 20W, 30W Power, can be connected to the cable, emergency power box.

The CES-EX-SF series explosion-proof ceiling lamp has a strong shell, with features such as impact resistance, vibration resistance, and corrosion resistance. It can be used in hazardous environments of Zone 1&21, Zone 2&22.

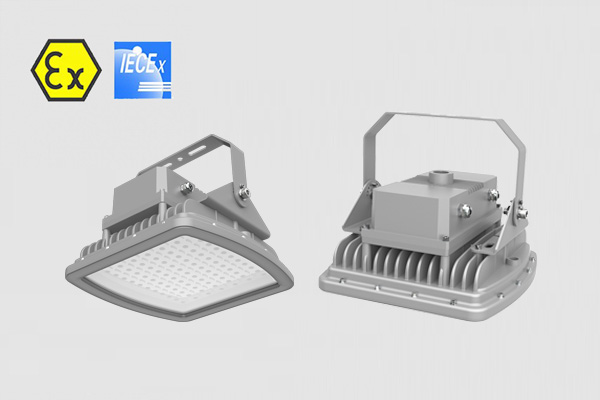

CES-EX-JX Series is your go-to solution for illuminating hazardous Zone 1 and Zone 21 areas. With ATEX approval, these Explosion-proof LED Flood Lights offer unbeatable safety standards.

Discover the pinnacle of safety and illumination with our CES-EX-GBX Series Explosion-proof LED High Bay Lights. Designed for hazardous Zone 1 and Zone 21 areas, these lights boast ATEX approval, ensuring the highest safety standards.

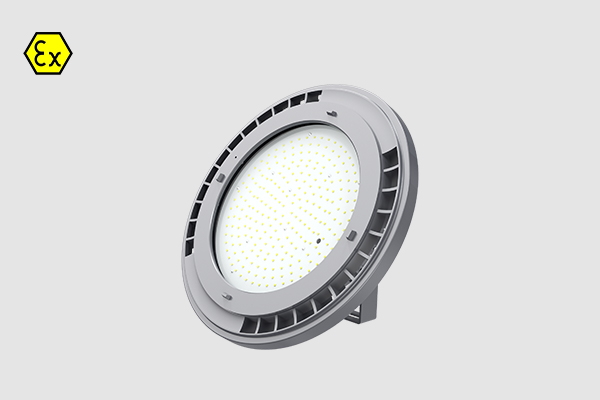

GB-02 explosion-proof lights are made of alloy aluminum and tempered glass, with shock resistance and anti-vibration performance. The luminaires have passed the ATEX IECEx standards test, from 30W to 80W for hazardous area lighting.

LN-02 explosion-proof lights obtained an IECEx ATEX certificate, it's safe for the Zone 1 and Zone 2 hazardous locations. The copper-free aluminum alloy body is powder-coated to increase durability and beautiful appearance, are able to withstand violent shaking and shock resistance.

an innovative line of LED hazardous area lighting products, specifically designed for use in potentially explosive atmospheres (Zone 1/21 & 2/22) within harsh industrial settings such as coal mines and oil & gas facilities.

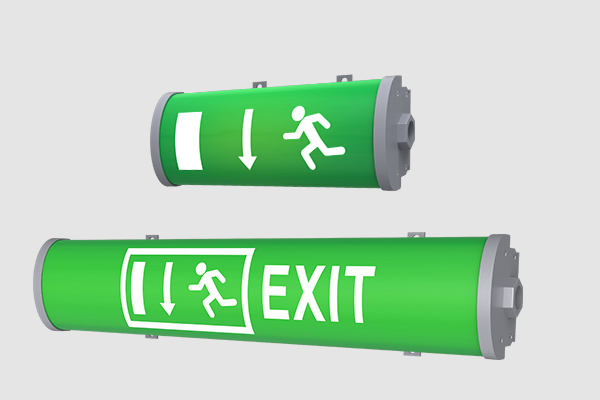

Explosion-proof safety exit lamps are for personnel evacuation, and fire operations to provide lighting fire emergency lamps! It usually uses an external power supply, when the power automatically switches to the battery power state!

Zone 1 Explosion Proof LED Linear Light - ATEX IECEx - 200W 240W 300W

Explosion Proof LED Linear Light - ATEX IECEx Zone 1 Zone 2 - 200W 240W 300W

Applications

Wastewater treatment,oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting, and where flammable vapors, gases, ignitable dusts, fibers or flyings are present.

Standard :

ATEX: EN IEC 60079-0-2018; EN 60079-7-2015; EN 60079-31-2014;

IECEx: IEC 60079-0-2017; IEC 60079-7-2015; IEC 60079-31-2013;

Warning:

IECEx& ATEX :

- “WARNING – DO NOT OPEN WHEN ENERGIZED”;

- “WARNING – DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT”;

- “WARNING – Potential Electrostatic Charging Hazard –Please wipe with a damp cloth when cleaning”;

- End user shall use certified cable gland suitable type of protection for final installation purpose;

- External earthing wire shall be connected when used and the cross-sectional area shall be more than 4mm²or 10AWG;

- Under rating condition, maximum temperature on the luminaire’s shell shall not be higher than 165℃ for T3. Temperature at cable inlet shall not be higher than allowable limit of the cable applied, to ensure the cable operation normally. For CES-EX-LN-02-80、CES-EX-LN-02-100、CES-EX-LN-02-120、CES-EX-LN-02-150, the branch point is 78.4℃ and cable entry point is 66.8℃

Features

- Luminous flux: 26000LM / 31200LM / 39000LM

- -40°C to + 50°C Ambient operating temperature

- 5 years warranty

- Entry Size: M25 X 1.5

- Housing – Aluminum alloy (ADC12 and 6063)

- Lens – Tempered glass

- LED Driver: Meanwell HLG series

Parameters

- Power: 200W / 240W / 300W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 120 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- Bean angle: 90° or 110°

- Dimension: 564*202*112mm (Single Fixture)

- Weight: 10.6KG

Certificate & Standard

IECEx Certificate No. : IECEx UL 22.0091X

- Ex ec IIC T *Gc

- Ex tb IIIC T *°C Db

- IP66

IECEx Certificate No. : ATEX Certificate No.: UL 22 ATEX 2543X, UL 22 ATEX 2544X

- II 3G Ex ec IIC T*Gc

- II 2D Ex tb IIIC T*Db

- IP66

Mounting

Versatile mounting options:

- Ceiling mount

- Drop mount

- Wall Mount

- Mounting Angle:0°to ±90°

Zone 1 Explosion Proof LED Linear Light - ATEX IECEx - 80W 100W 120W 150W

Explosion Proof LED Linear Light - ATEX IECEx Zone 1 Zone 2 - 80W 100W 120W 150W

Applications

Wastewater treatment,oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting, and where flammable vapors, gases, ignitable dusts, fibers or flyings are present.

Standard :

ATEX: EN IEC 60079-0-2018; EN 60079-7-2015; EN 60079-31-2014;

IECEx: IEC 60079-0-2017; IEC 60079-7-2015; IEC 60079-31-2013;

Warning:

IECEx& ATEX :

- “WARNING – DO NOT OPEN WHEN ENERGIZED”;

- “WARNING – DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT”;

- “WARNING – Potential Electrostatic Charging Hazard –Please wipe with a damp cloth when cleaning”;

- End user shall use certified cable gland suitable type of protection for final installation purpose;

- External earthing wire shall be connected when used and the cross-sectional area shall be more than 4mm²or 10AWG;

- Under rating condition, maximum temperature on the luminaire’s shell shall not be higher than 165℃ for T3. Temperature at cable inlet shall not be higher than allowable limit of the cable applied, to ensure the cable operation normally. For CES-EX-LN-02-80、CES-EX-LN-02-100、CES-EX-LN-02-120、CES-EX-LN-02-150, the branch point is 78.4℃ and cable entry point is 66.8℃

Features

- Luminous flux: 10400LM / 13000LM / 15600LM / 19500LM

- -40°C to +50°C Ambient operating temperature

- 5 years warranty

- Entry Size: M25 X 1.5

- Housing – Aluminum alloy (ADC12 and 6063)

- Lens – tempered glass

- LED Driver: Meanwell HLG series

Parameters

- Power:80W/100W/120W / 150W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 120 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- Bean angle: 90° or 110°

- Dimension: 564*202*112mm

- Weight: 10.6KG

Certificate & Standard

IECEx Certificate No. : IECEx UL 22.0091X

- Ex ec IIC T *Gc

- Ex tb IIIC T *°C Db

- IP66

IECEx Certificate No. : ATEX Certificate No. : UL 22 ATEX 2543X, UL 22 ATEX 2544X

- II 3G Ex ec IIC T*Gc

- II 2D Ex tb IIIC T*Db

- IP66

Mounting

Versatile mounting options:

- Ceiling mount

- Drop mount

- Wall Mount

- Mounting Angle:0°to ±90°

Zone 1 Explosion Proof LED Linear Light - ATEX IECEx - 40W 50W 60W

Explosion Proof LED Linear Light - ATEX IECEx Zone 1 Zone 2 - 40W 50W 60W

Applications

Wastewater treatment,oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting, and where flammable vapors, gases, ignitable dusts, fibers or flyings are present.

Standard :

ATEX: EN IEC 60079-0-2018; EN 60079-7-2015; EN 60079-31-2014;

IECEx: IEC 60079-0-2017; IEC 60079-7-2015; IEC 60079-31-2013;

Warning:

IECEx& ATEX :

- “WARNING – DO NOT OPEN WHEN ENERGIZED”;

- “WARNING – DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT”;

- “WARNING – Potential Electrostatic Charging Hazard –Please wipe with a damp cloth when cleaning”;

- End user shall use certified cable gland suitable type of protection for final installation purpose;

- External earthing wire shall be connected when used and the cross-sectional area shall be more than 4mm²or 10AWG;

- Under rating condition, maximum temperature on the luminaire’s shell shall not be higher than 165℃ for T3. Temperature at cable inlet shall not be higher than allowable limit of the cable applied, to ensure the cable operation normally. For CES-EX-LN-02-40、CES-EX-LN-02-50、CES-EX-LN-02-60, the branch point is 61.8℃ and cable entry point is 57.5℃.

Features

- Luminous flux: 5200LM / 6500LM / 7800LM

- -40°C to +50°C Ambient operating temperature

- 5 years warranty

- Entry Size: M25 X 1.5

- Housing –Aluminum alloy (ADC12 and 6063)

- Lens –tempered glass

- LED Driver: Meanwell HLG series

Parameters

- Power:40W/50W/60W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 120 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- Bean angle: 90° or 110°

- Dimension: 596*126*114mm

- Weight: 7.5KG

Certificate & Standard

IECEx Certificate No. : IECEx UL 22.0091X

- Ex ec IIC T *Gc

- Ex tb IIIC T *°C Db

- IP66

IECEx Certificate No. : ATEX Certificate No. : UL 22 ATEX 2543X, UL 22 ATEX 2544X

- II 3G Ex ec IIC T*Gc

- II 2D Ex tb IIIC T*Db

- IP66

Mounting

Versatile mounting options:

- Ceiling mount

- Drop mount

- Wall Mount

- Mounting Angle:0°to ±90°

Explosion Proof LED Light - IECEx ATEX Zone 21 - 30W 40W

Zone 21 Explosion Proof LED Light - ATEX IECEx - 30W 40W

Applications

Wastewater treatment,oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall, and stanchion mounted general area lighting, and where flammable vapors, gases, ignitable dusts, fibers or flyings are present.

Standard :

ATEX: EN IEC 60079-0-2018; EN 60079-7-2015; EN 60079-31-2014;

IECEx: IEC 60079-0-2017; IEC 60079-7-2015; IEC 60079-31-2013;

Warning:

IECEx& ATEX :

- “WARNING – DO NOT OPEN WHEN ENERGIZED”;

- “WARNING – DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT”;

- “WARNING – Potential Electrostatic Charging Hazard –Please wipe with a damp cloth when cleaning”;

- End user shall use a certified cable gland suitable type of protection for final installation purpose;

- External earthing wire shall be connected when used and the cross-sectional area shall be more than 4mm² or 10AWG;

- Under rating conditions, the maximum temperature on the luminaire’s shell shall not be higher than 130℃ for T4. Temperature at cable inlet shall not be higher than allowable limit of the cable applied, to ensure the cable operation normally. For CES-EX-GB-02-30、CES-EX-GB-02-40,The branch point is 57.3℃ and the cable entry point is 52.3℃.

Features

- Luminous flux: 3900lm / 5200lm

- -40°C to +50°C ambient operating temperature

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: M25*1.5

- Housing – Aluminum alloy (ADC12)

- Lens – tempered glass

- Dimension: 200*157mm

- Weight: 3KG

Parameters

- Power: 30W / 40W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 120 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: Meanwell brand

Certificate & Standard

Certifications and compliances for hazardous location.

-

IECEx Certificate No. : IECEx UL 22.0091X

• Ex ec IIC T4 Gc

• Ex tb IIIC T 79°C Db

• IP66 -

ATEX Certificate No. : UL 22 ATEX 2543X, UL 22 ATEX 2544X

• II 3G Ex ec IIC T3...T4...T5 Gc

• II 2D Ex tb IIIC T*Db

• IP66

Mounting

Versatile mounting options:

- Ceiling mount

- Pole mount

Explosion Proof LED Light - IECEx ATEX Zone 21 - 60W 80W

Zone 21 Explosion Proof LED Light - ATEX IECEx - 60W 80W

Applications

Wastewater treatment,oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall, and stanchion mounted general area lighting, and where flammable vapors, gases, ignitable dusts, fibers or flyings are present.

Standard :

ATEX: EN IEC 60079-0-2018; EN 60079-7-2015; EN 60079-31-2014;

IECEx: IEC 60079-0-2017; IEC 60079-7-2015; IEC 60079-31-2013;

Warning:

IECEx& ATEX :

- “WARNING – DO NOT OPEN WHEN ENERGIZED”;

- “WARNING – DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT”;

- “WARNING – Potential Electrostatic Charging Hazard –Please wipe with a damp cloth when cleaning”;

- End user shall use certified cable gland suitable type of protection for final installation purpose;

- External earthing wire shall be connected when used and the cross-sectional area shall be more than 4mm² or 10AWG;

- Under rating condition, maximum temperature on the luminaire’s shell shall not be higher than 130℃ for T4. Temperature at cable inlet shall not be higher than allowable limit of the cable applied, to ensure the cable operation normally. For CES-EX-GB-02-60、CES-EX-GB-02-80,The branch point is 58.2℃ and cable entry point is 52.6℃;

Features

- Luminous flux: 7800lm / 10400lm

- -40°C to +50°C ambient operating temperature

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: M25 * 1.5

- Housing – Aluminum alloy (ADC12)

- Lens – tempered glass

- Dimension: 300*204mm

- Weight: 7KG

Parameters

- Power: 60W / 80W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 120 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: Meanwell HBG series

Certificate & Standard

Certifications and compliances for hazardous location.

-

IECEx Certificate No. : IECEx UL 22.0091X

• Ex ec IIC T 79Gc

• Ex tb IIIC T4 Db;

• IP66; -

ATEX Certificate No. : UL 22 ATEX 2543X, UL 22 ATEX 2544X

• II 3G Ex ec IIC T3...T4...T5 Gc;

• II 2D Ex tb IIIC T*Db;

• IP66;

Mounting

Versatile mounting options:

- Ceiling mount

- Pole mount

Explosion Proof Emergency Exit Lights - 12W - 2ft - 180 mins Battery Backup

CES-EX-LN-02P-E series 2ft length explosion proof class 1 division 2 exit sign with an backup Li-ion battery that provides 180 mins (3 hours) operation, output 1440 lumen flux.

This explosion proof led exit sign, can used for the hazard location of Class 1 Div 2 Groups A, B, C and D. For design and structure, it made of the die-cast aluminum and the PC cover. Good heat, and 6J impact resistance.

Remark: if you need IECEx and ATEx certified, please visit to 1ft / 2ft emergency epxlosion proof exit sign of Zone 1.

ATEX: EN IEC 60079-0-2018; EN 60079-7-2015; EN 60079-18-2015; EN 60079-31-2014;

IECEx: IEC 60079-0-2017; IEC 60079-7-2015; IEC 60079-18-2014; IEC 60079-31-2013;

-

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING __55__ °C (_131 °F);

- MIN 90°C (194°F) SUPPLY CONDUCTORS;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Industry-leading efficacy: up to 120lm/W±5

- -40°C to +45°C /50°C /55°CAmbient operating temperature

- 5 years warranty

- Entry Size: NPT 3/4”-14

- Material : Aluminum alloy (ADC12 ) + PC

Parameters

- Power (Normal lighting): 12W

- Voltage: AC100-277V or DC24V

- Power factor: 0.97

- Lumen flux: 11440LM

- CCT: 5500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: High efficiency driver

- Dimension: 629 mm x 125mm x 88.7 mm

- Weight: 3.0KG

- Emergency time: >= 3.0 hours (180 mins)

Certificate & Standard

Have certified CES-EX-LN-02P fixtures with the UL844 standards for hazardous location and environments.

NEC/CEC:

- Class I, Division 2, Groups A, B, C and D

- T-Class: T4A / T5

- Damp and wet locations

- Certify No:E475887

Standard:

- US: UL 844; UL 1598;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Amounting

Versatile mounting options:

- Wall Ceiling mounting

Explosion Proof Exit Emergency Lights - 12W - 2ft - 180 mins Battery Backup

This 0.6 meters Explosion Proof emergency lighting is designed as the exit sign, it is available as an AC (100V - 277V) or DC 24V version, but it is available with a self-contained battery, no less than 90 min or 180 min backup for emergency use.

Features

- Industry-leading efficacy: up to 120lm/W±5

- -40°C to +45°C /50°C /55°CAmbient operating temperature

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: M25Χ1.5 or NPT 3/4”-14

- Material : Aluminum alloy (ADC12 ) + PC

Parameters

- Power (Normal lighting): 20W / 30W / 40W/ 50W

- Input voltage: AC100-277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 2400LM / 3600LM / 4800LM / 6000LM

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: High efficiency driver

- Dimension: 629 mm x 125mm x 88.7 mm

- Weight: 3.2KG (2 Foot)

- Emegency function: Yes

- Output voltage: DC24V

- Emergency: >= 3.0 hours (180 mins)

- Emergency power: 12W

- Emergency lumen flux: 1440LM

Amounting

Versatile mounting options:

- Wall Ceiling mounting

5W Explosion Proof Exit Light - Zone 1 Zone 21 - 180 mins Battery Backup

This Explosion Proof emergency lighting is designed as the exit sign, it is available as an AC (100V - 277V) or DC 24V version, but it is available with a self-contained battery, no less than 90 min or 180 min back up for emergency use.

Applications: In harsh and hazardous environments where illuminated exit signs are required.

Features

- Industry-leading efficacy: up to 120lm/W±5

- -40°C to +45°C /50°C /55°CAmbient operating temperature

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: M25Χ1.5 or NPT 3/4”-14

- Material : Aluminum alloy (ADC12 ) + PC

Parameters

- Power: 5W

- Input voltage: AC100-277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 600LM

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: High efficiency driver

- Dimension: 329 mm x 125mm x 88.7 mm

- Weight: 2.5KG (1 Foot)

- Emegency function: Yes

- output voltage: DC24V

- Emergency: > 3.0 hours (180 mins)

Amounting

Versatile mounting options:

- Wall Ceiling mounting

Explosion Proof Box Lighting - 2ft Linear Lights - Italy

Luminaires: CES-EX-LN-02P, 2 Feet explosion proof linear lights

Italy - these luminaries are installed in explosion-proof boxes

Explosion-proof box is generally used in the hazardous area of gas explosion or dust explosion environment, so the explosion-proof box itself uses explosion-proof structure. For the second area, in accordance with common sense, the electrical components inside the explosion-proof box (online monitoring instruments, distribution box equipment,) do not need to explosion-proof function, but in the use and maintenance process if the internal electrical components are ordinary, it will cause great difficulties in the maintenance and repair of the equipment.

For example, in the normal operation of the explosion-proof box, suddenly there is a problem in the online monitoring equipment, maintenance personnel need to enter the internal maintenance, then the explosion-proof box needs to be treated with power off, after the power off the air conditioning system in the box, lighting system will lose effect, in the hot summer or night maintenance is very inconvenient, so the explosion-proof box is best made of internal and external explosion-proof type.

Safety Precautions for Oil Tank Maintenance

In the maintenance of oil tank area, we need to pay attention to some matters to ensure the safety of maintenance personnel and the smooth maintenance work.

- The storage tanks storing flammable gas and flammable liquid should be equipped with necessary fire fighting equipment. Smoking, lighting and heating with open flame are strictly prohibited in the tanks, and the ignition source is prohibited to be brought into the tank area.

- For storage tanks with inflammable, explosive, toxic, corrosive and other media, the relevant regulations of dangerous goods management shall be strictly implemented.

- Before the inspection and repair of the storage tank, the power supply of the electrical equipment related to the storage tank must be cut off, and the equipment handover procedures must be completed.

- After the internal media of the storage tank is drained, the inlet and outlet valve should be closed or the blind plate should be added to cut off the pipeline and equipment connected with it, and there is an obvious partition sign.

- For storage tanks containing flammable, corrosive, toxic, or asphyxiating media, they must be replaced, neutralized, disinfected, cleaned, etc., and analyzed and inspected after treatment. The analysis results should meet the provisions of relevant specifications and standards. It is strictly prohibited to use air replacement with flammable medium.

- 30 minutes before entering the tank operation to sample analysis, its oxygen content is between 18-23%(volume ratio).

- When entering the tank to clean up toxic and corrosive residue, wear personal protective equipment.

- Need to build the scaffold and lifting device, must be firm and reliable, in the operation is strictly prohibited to throw material tools inside and outside, in order to ensure safe operation.

- The tank lighting should use the voltage is not more than 24Vexplosion-proof lamps.

CESP SC-series explosion proof led hand lamp is suitable for the inspection working in the hazardous location. ATEX IECEX Zone 1 Zone 21 and UL844-Class 1 Division 1 approved.

- Tank operations must have guardians, and reliable contact measures.

- At the time of completion, maintenance personnel and guardianship personnel jointly check the inside and outside of the tank. After it is confirmed, the guardian can close the manholes only after signing the operation certificate in the tank.