IECEx ATEX Certified Explosion proof LED Lights - Zone 1 Zone 2 Hazardous Area Lighting

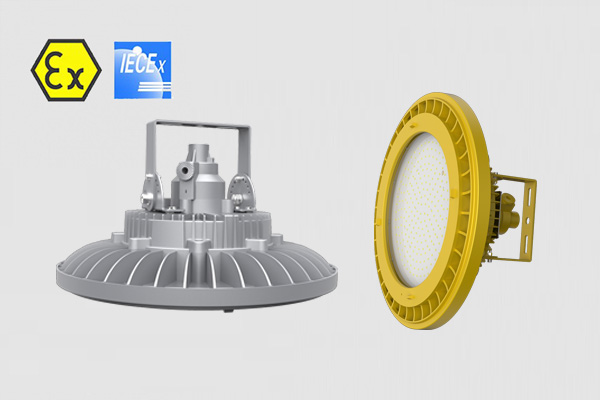

For Zone 1 Zone 2, Zone 21 Zone 22 hazardous area led lighting, 20W - 200W, 130lm/W,aluminum alloy + 8mm tempered glass, multi-installation for different projects, such as light tower, canopy light, marine grade.

Flameproof enclosure, Ex db op is IIC T6 Gb, Zone 1 & Zone 21 with explosive gas atmosphere, Zone 21 and Zone22 with explosive dust atmosphere, 10mm temered glass, 7J impact resistance,up to 26000lm.

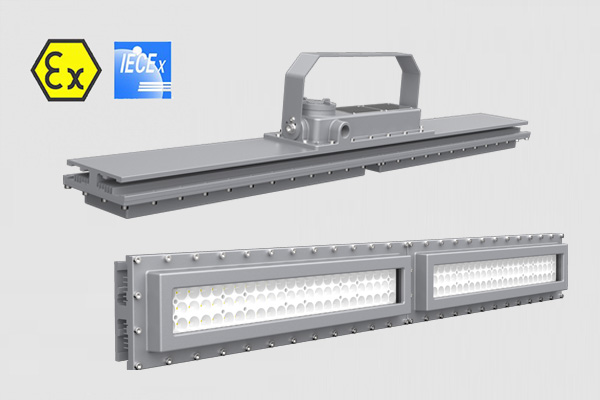

Flameproof enclosure, Ex db op is IIC T6 Gb, IP68 protection grade, tempered glass 10mm, withstand impacts up to 10J, 2 foot and 4 foot Length, 50Watt- 240Watt, 130lm/W light efficacy.

Zone 1 & Zone 21, 1ft, 2ft, 3ft, 4ft length can be selected, replace the traditional explosion-proof three-proof lamp, explosion-proof fluorescent tube, anti-corrosion, anti-glare, anti-drop, competitive price.

Flameproof LED hand lamp for Zone 1 & Zone 21 hazardous areas, 10mm tempered glass, pass the multi-angle drop test, 10W, 20W, 30W Power, can be connected to the cable, emergency power box.

The CES-EX-SF series explosion-proof ceiling lamp has a strong shell, with features such as impact resistance, vibration resistance, and corrosion resistance. It can be used in hazardous environments of Zone 1&21, Zone 2&22.

CES-EX-JX Series is your go-to solution for illuminating hazardous Zone 1 and Zone 21 areas. With ATEX approval, these Explosion-proof LED Flood Lights offer unbeatable safety standards.

Discover the pinnacle of safety and illumination with our CES-EX-GBX Series Explosion-proof LED High Bay Lights. Designed for hazardous Zone 1 and Zone 21 areas, these lights boast ATEX approval, ensuring the highest safety standards.

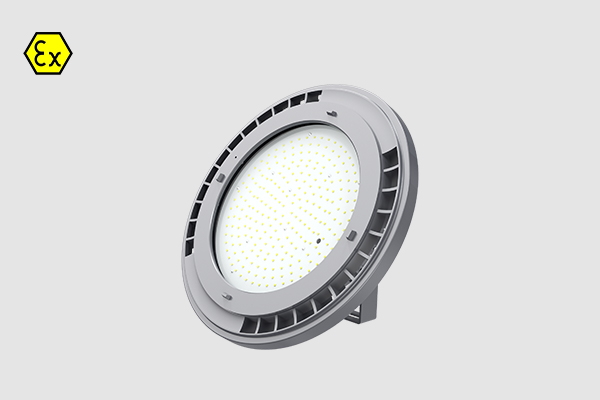

GB-02 explosion-proof lights are made of alloy aluminum and tempered glass, with shock resistance and anti-vibration performance. The luminaires have passed the ATEX IECEx standards test, from 30W to 80W for hazardous area lighting.

LN-02 explosion-proof lights obtained an IECEx ATEX certificate, it's safe for the Zone 1 and Zone 2 hazardous locations. The copper-free aluminum alloy body is powder-coated to increase durability and beautiful appearance, are able to withstand violent shaking and shock resistance.

an innovative line of LED hazardous area lighting products, specifically designed for use in potentially explosive atmospheres (Zone 1/21 & 2/22) within harsh industrial settings such as coal mines and oil & gas facilities.

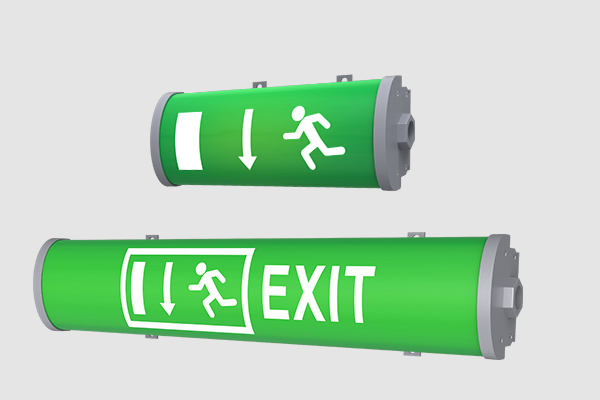

Explosion-proof safety exit lamps are for personnel evacuation, and fire operations to provide lighting fire emergency lamps! It usually uses an external power supply, when the power automatically switches to the battery power state!

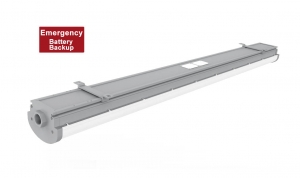

4ft Class 1 Division 2 Emergency Linear Lights - 90 min backup battery

Description:

CES-EX-LN-02P-E series 4ft length emergency explosion proof linear LED fixtures, 40W, 50W, 60W, 65W, 70W, 75W power, with an backup ( 12 Watt ) Li-ion battery that provides energy efficient illumination, the emergency backup provide 1680 lumens for the 1.5 hours.

This linear hazardous location LED fixtures on only obtained UL844 certificate, can used for the hazard location of Class 1 Div 2 Groups A, B, C and D. For design and structure, this emergency hazardous location LED fixtures made of the die-cast aluminum and the PC cover. Good heat, and 6J impact resistance.

In addition, we designed this fixtures for marine location ( UL1598A certificate), we adopt to the electrophoresis technology and the multiple coats of marine anti-corrosion paint, the all the mounting brackets and accessories are made of 316 stainless steel, UL1598A anti-corrosion standard can for marine location.

For the optics, adopt to the high light efficacy LED source, up to 140lm/W, the CCT 2700K, 3000K, 4000K, 5000K, 5700K, 6500K optional, no flicker, no glare.

If you need IECEx and ATEx certified, please visit to 4ft emergency epxlosion proof linear lights of Zone 1.

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING __55__ °C (_131 °F);

- MIN 90°C (194°F) SUPPLY CONDUCTORS;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Industry-leading efficacy: up to 110 - 130lm/W

- -40°C to + 50°C Ambient operating temperature

- Mounting: Ceiling

- 5 years warranty

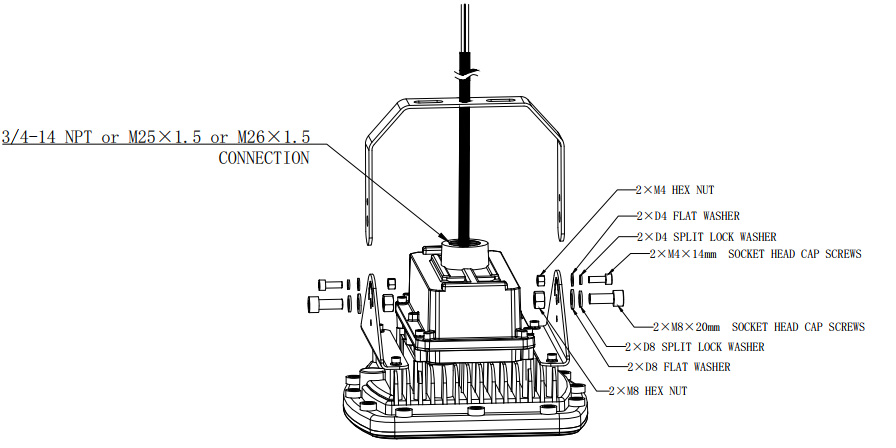

- Entry Size: NPT 3/4”-14

- Housing –Aluminum alloy (ADC12 and 6063 )

- Lens – Polycarbonate (PC)

- Beam angle:120°

Parameters

- Power: 40W / 50W / 60W / 65W / 75W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 4800LM / 6000LM / 7200LM / 7800LM / 9000LM

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: high Efficiency LED Driver

- Dimension: 1229 mm x 138.3mm x 98.1 mm

- Weight: 5.5KG

- Backup battery: Li-ion battery, 12W power

- Emergency: ≥90 mins

Certificate & Standard

Have certified CES-EX-LN-02P fixtures with the North American UL844 standards for hazardous location and environments.

NEC/CEC:

- Class I, Division 2, Groups A, B, C and D

- T-Class: T4A / T5

- Damp and wet locations

- Certify No:E475887

Standard:

- US: UL 844; UL 1598;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Special order

- Special Orders- Requirements

Contact us for special requirements

Tel: +86-755-83509822

Fax: +86-755-83509868

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

2ft Class 1 Division 2 Emergency Linear Lights - 90 min backup battery

Description:

CES-EX-LN-02P-E series 2ft length emergency explosion proof linear LED fixtures with an backup Li-ion battery that provides energy efficient illumination, the emergency backup provide 1680 lumens for the 1.5 hours.

This linear hazardous location LED fixtures on only obtained UL844 certificate, can used for the hazard location of Class 1 Div 2 Groups A, B, C and D. For design and structure, this emergency hazardous location LED fixtures made of the die-cast aluminum and the PC cover. Good heat, and 6J impact resistance.

In addition, we designed this fixtures for marine location ( UL1598A certificate), we adopt to the electrophoresis technology and the multiple coats of marine anti-corrosion paint, the all the mounting brackets and accessories are made of 316 stainless steel, UL1598A anti-corrosion standard can for marine location.

For the optics, adopt to the high light efficacy LED source, up to 140lm/W, the CCT 2700K, 3000K, 4000K, 5000K, 5700K, 6500K optional, no flicker, no glare.

If you need IECEx and ATEx certified, please visit to 2ft emergency epxlosion proof linear lights of Zone 1.

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING __55__ °C (_131 °F);

- MIN 90°C (194°F) SUPPLY CONDUCTORS;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Industry-leading efficacy: up to 110 - 130lm/W

- -40°C to + 50°C Ambient operating temperature

- Mounting: Ceiling

- 5 years warranty

- Entry Size: NPT 3/4”-14

- Housing –Aluminum alloy (ADC12 and 6063 )

- Lens – Polycarbonate (PC)

- Beam angle:120°

Parameters

- Power: 30W / 40W / 50W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 2600LM / 4800LM / 6000LM

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: high Efficiency LED Driver

- Dimension: 629 mm x 125mm x 88.7 mm

- Weight: 3.0KG

- Backup battery: Li-ion battery, 12W power

- Emergency: ≥90 mins

Certificate & Standard

Have certified CES-EX-LN-02P fixtures with the North American UL844 standards for hazardous location and environments.

NEC/CEC:

- Class I, Division 2, Groups A, B, C and D

- T-Class: T4A / T5

- Damp and wet locations

- Certify No:E475887

Standard:

- US: UL 844; UL 1598;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Special order

- Special Orders- Requirements

Contact us for special requirements

Tel: +86-755-83509822

Fax: +86-755-83509868

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

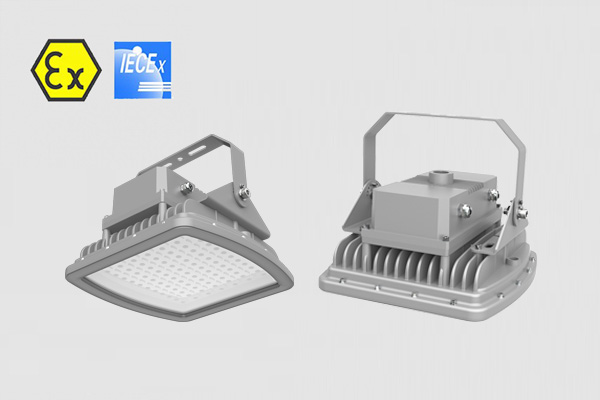

Explosion Proof Emergency Lighting - 1.5 Hours - 120W/150W/180W/200W

Explosion Proof Emergency Lighting - 1.5 Hours - 60W/80W/100W

Description:

This explosion proof emergency flood light fixtures with an emergency backup battery (12W Li-ion battery), the emergency backup lighting provide 1680 lumens for the 1.5 hours. For the normal lighting , the input voltage is AC100 - 277V, 60W, 80W, 100W power optional.

For design and structure, this emergency explosion proof light made of the die-cast aluminum and the 8mm high tempered glass. Good heat and 6J impact resistance.

If you need anti-corrosion performance for the marine environment, that is optional. We adopt to the electrophoresis technology and the multiple coats of marine anti-corrosion paint, the all the mounting brackets and accessories are made of 316 stainless steel. Certified by UL1598A and CCS.

Design standard of CES-J: EN 60079-0: 2013 ; EN 60079-7: 2015 ; EN 60079-18: 2015 ; EN 60079-28: 2015 ; EN 60079-31:2014;

Warning:

- “WARNING – DO NOT OPEN WHEN ENERGIZED”

- “WARNING – DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT”

- “WARNING – ONLY USE CABLES SUITABLE FOR 85°C”

- End user shall use certified cable gland or conduit with suitable type of protection for final installation purpose.

- External earthing wire shall be connected when used and the cross-sectional areashall be more than 4mm2 or 10AWG.

- Under rating condition, maximum temperature on the luminaire’s shell shall not be higher than 95℃ for T4.Temperature at cable inlet shall not be higher than allowable limit of the cable applied, to ensure the cable operation normally.

Features

- Industry-leading efficacy: up to 130lm/W±5

- -40°C to +55°C Ambient operating temperature

- Amounting: U-bracket

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: M25Χ1.5 or NPT 3/4”-14

- Housing –Aluminum alloy (ADC12 )

- Lens – tempered glass

- Beam angle: 8°, 15°, 35°, 60°, 90°, 108°, 120°

Parameters

- Power:60W/80W/100W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 7200lm / 9600lm / 12000lm

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030

- LED Driver: Meanwell HLG series

- Dimension: 300mm x300mm x 165(251)mm

- Weight: 7.5KG

- Backup battery: Li-ion battery, 12W power

- Emergency: ≥90 mins

Certificate & Standard

Have certified CES-J light fixtures with the IECEX and ATEX standards for hazardous location and environments.

ATEX:

- EX II 2G Ex eb mb op is IIC T4 Gb

- EX II 2D Ex op is tb IIIC T95°C Db

- IP66

- Certify No:IEP 19ATEX 0714

IECEx:

- Ex ec IIC T4 Gc

- IP66

- Certify No:IECEx UL 18.0046

Special order

- Special Orders- Requirements

Contact us for special requirements

Tel: +86-755-83509822

Fax: +86-755-83509868

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Explosion Proof Emergency Lighting - 1.5Hours - 20W/30W/40W

Description:

This explosion proof emergency flood light fixtures with an emergency backup battery (12W Li-ion battery), the emergency backup lighting provide 1680 lumens for the 1.5 hours. For the normal lighting , the input voltage is AC100 - 277V, 20W, 30W, 40W power optional.

If you need anti-corrosion performance for the marine environment, that is optional. We adopt to the electrophoresis technology and the multiple coats of marine anti-corrosion paint, the all the mounting brackets and accessories are made of 316 stainless steel. Certified by UL1598A and CCS.

• Applies to hazardous locations of Zone 1 and Zone2 with explosive gas atmosphere.

• Applies to hazardous locations of Zone 21 and Zone22 with explosive dust atmosphere.

Design standards: EN 60079-0: 2013 ; EN 60079-7: 2015 ; EN 60079-18: 2015 ; EN 60079-28: 2015 ; EN 60079-31:2014;

Warning:

- “WARNING – DO NOT OPEN WHEN ENERGIZED”

- “WARNING – DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT”

- “WARNING – ONLY USE CABLES SUITABLE FOR 85°C”

- End user shall use certified cable gland or conduit with suitable type of protection for final installation purpose.

- External earthing wire shall be connected when used and the cross-sectional areashall be more than 4mm2 or 10AWG.

- Under rating condition, maximum temperature on the luminaire’s shell shall not be higher than 95℃ for T4.Temperature at cable inlet shall not be higher than allowable limit of the cable applied, to ensure the cable operation normally.

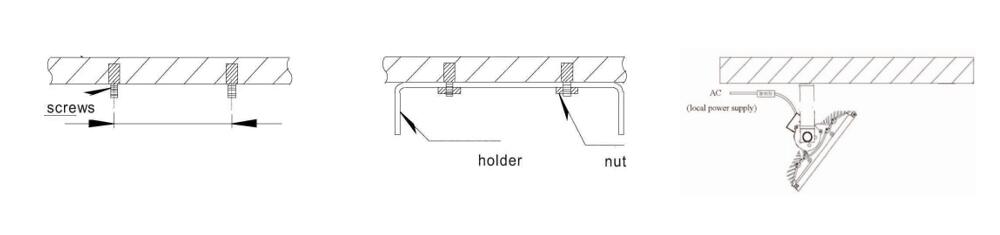

Mounting:

Fix 2 M10 screws on the wall according to the distance between the holes of the bracket. Install the bracket on the screws and then fasten it with the nut. Fix the position of the lamp Place the lamp cord into the pole; connect the wire to local power supply (AC100-277V).

Features

- Industry-leading efficacy: up to 140lm/W

- -40°C to +55°C Ambient operating temperature

- Amounting: U-bracket

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: M25Χ1.5 or NPT 3/4”-14

- Housing –Aluminum alloy (ADC12 )

- Lens – tempered glass

- Beam angle: 8°, 15°, 35°, 60°, 90°, 108°, 120°

Parameters

- Power:20W / 30W / 40W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 2400lm / 3600lm / 4800lm

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030

- LED Driver: Meanwell HLG series

- Dimension: 200mm*200mm*147mm

- Weight: 4KG

- Backup battery: Li-ion battery, 12W power

- Emergency: ≥90 mins

Certificate & Standard

Have certified CES-J fixtures with the IECEX and ATEX standards for hazardous location and environments.

ATEX:

- EX II 2G Ex eb mb op is IIC T4 Gb

- EX II 2D Ex op is tb IIIC T95°C Db

- IP66

- Certify No.:IEP 19ATEX 0714

IECEx:

- Ex ec IIC T4 Gc

- IP66

- Certify No:IECEx UL 18.0046

Special order

- Contact us for special requirements

Tel: +86-755-83509822

Fax: +86-755-83509868

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Explosion Proof Emergency Light 1.5 Hours - Class 1 Division 2 - 120W/150W/185W

Features:

CES-J120/J150/185 hazardous location emergency light fixtures with an emergency backup battery that provides energy-efficient illumination, the emergency backup provides 1680 lumens for 1.5 hours. For normal lighting, the input voltage is AC100 - 277V, 120W, 150W, 185W power optional, up to 25900-lumen flux. These floodlight hazardous location LED fixtures only obtained UL844, and can use for Class 1 Div 2, Groups A, B, C, and D. For design and structure, these emergency hazardous location LED fixtures are made of die-cast aluminum, and the 8mm high tempered glass. Good heat, and 6J impact resistance.

If you need anti-corrosion performance for the marine environment, that is optional. We adapt to the electrophoresis technology and multiple coats of marine anti-corrosion paint, all the mounting brackets and accessories are made of 316 stainless steel.

Warning:

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING 40°C;

- FOR SUPPLY CONNECTION, USE WIRES RATED FOR AT LEAST90°C;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

UL for marine locations:

- OUTSIDE TYPE or OUTSIDE TYPE (SALT WATER);

Features

- Industry-leading efficacy: up to 140 lm/W

- -40°C to +55°C Ambient operating temperature

- Wide optics for uniform illumination

- Entry Size: NPT 3/4”-14 ;

- Housing –Aluminum alloy (ADC12 );

- Lens –tempered glass

- Beam angle: 108°, 120°

- Dimension: 400x400x169mm

- Weight: 10.5kg

Parameters

- Power: 120W/ 150W / 185W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 120 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: Meanwell HLG series

- Backup battery: Li-ion battery, 12W power

- Emergency: ≥90 mins

Certificate & Standard

Have certified CES-J fixtures with the NEC and CEC standards for hazardous location and environments

- Class I, Division 2, Groups A, B, C and D

- T-Class: T5

- Damp and wet locations

- Certificate No:E475887

- US: UL 844; UL 1598A;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0;

Mounting

Versatile mounting options:

- Ceiling mount

- Drop mount

- Pole mount

- Wall Mount

- Mounting Angle:0°to ±90°;

Explosion Proof Emergency Light 1.5 Hours - Class 1 Division 2 - 60W/80W/100W

Features:

CES-J SERIES hazardous location emergency light fixtures with an emergency backup battery that provides energy-efficient illumination, the emergency backup provides 1680 lumens for 1.5 hours. For normal lighting, the input voltage is AC100 - 277V, 60W, 80W, 100W power optional, up to 14000-lumen flux.

These floodlight hazardous location LED fixtures only obtained UL844, and can use for Class 1 Div 2, Groups A, B, C, and D. For design and structure, these emergency hazardous location LED fixtures are made of die-cast aluminum, and the 8mm high tempered glass. Good heat, and 6J impact resistance.

If you need anti-corrosion performance for the marine environment, that is optional. We adapt to the electrophoresis technology and the multiple coats of marine anti-corrosion paint, all the mounting brackets and accessories are made of 316 stainless steel.

Warning:

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING 40°C;

- FOR SUPPLY CONNECTION, USE WIRES RATED FOR AT LEAST90°C;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

UL for marine locations:

- OUTSIDE TYPE or OUTSIDE TYPE (SALT WATER);

Features

- Industry-leading efficacy: up to 140lm/W

- -40°C to +55°C Ambient operating temperature

- Wide optics for uniform illumination

- Fixture warranty

- Entry Size: NPT 3/4”-14 ;

- Housing –Aluminum alloy (ADC12 );

- Lens –tempered glass

- Beam angle: 108°, 120°

- Dimension: 300x300x165mm

- Weight: 7.5kg

Parameters

- Power: 60W / 80W / 100W

- Input voltage: AC100 - 277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 110 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: Meanwell HLG series

- Backup battery: Li-ion battery, 12W power

- Emergency: ≥90min

Certificate & Standard

Have certified CES-J fixtures with the NEC and CEC standards for hazardous location and environments

- Class I, Division 2, Groups A, B, C and D

- T-Class: T6

- Damp and wet locations

- Certificate No:E475887

- US: UL 844; UL 1598A;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0;

Mounting

Versatile mounting options:

- Ceiling mount

- Drop mount

- Pole mount

- Wall Mount

- Mounting Angle:0°to ±90°;

Explosion Proof Emergency Light 1.5 Hours - Class 1 Division 2 - 20W/30W/40W

Features:

CES-J40S explosion-proof light fixtures with an emergency backup battery that provides energy-efficient illumination, the emergency backup provides 1680 lumens for 1.5 hours. For normal lighting, the input voltage is AC100 - 277V, 20W, 30W, and 40W power optional.

These floodlight hazardous location LED fixtures only obtained UL844, and can use for Class 1 Div 2, Groups A, B, C, and D. For design and structure, these emergency hazardous location LED fixtures are made of die-cast aluminum, and the 8mm high tempered glass. Good heat, and 6J impact resistance.

If you need anti-corrosion performance for the marine environment, that is optional. We adapt to the electrophoresis technology and the multiple coats of marine anti-corrosion paint, all the mounting brackets and accessories are made of 316 stainless steel.

Warning:

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING 40°C;

- FOR SUPPLY CONNECTION, USE WIRES RATED FOR AT LEAST90°C;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

UL for marine locations:

- OUTSIDE TYPE or OUTSIDE TYPE (SALT WATER);

Features

- Industry-leading efficacy: up to 130 lm/W

- -40°C to +55°C Ambient operating temperature

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: NPT 3/4”-14 ;

- Housing –Aluminum alloy (ADC12 );

- Lens – tempered glass

- Beam angle: 108°, 120°

- Dimension: 200x200x147mm

- Weight: 4kg

Parameters

- Power: 20W, 30W, 40W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 120 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: Meanwell HLG series

- Backup battery: Li-ion battery, 12W power

- Emergency: ≥90min

Certificate & Standard

Have certified CES-J fixtures with the NEC and CEC standards for hazardous location and environments

- Class I, Division 2, Groups A, B, C and D

- T-Class: T6

- Damp and wet locations

- Certificate No:E475887

- US: UL 844; UL 1598A;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0;

Mounting

Versatile mounting options:

- Ceiling mount

- Drop mount

- Pole mount

- Wall Mount

- Mounting Angle:0°to ±90°;

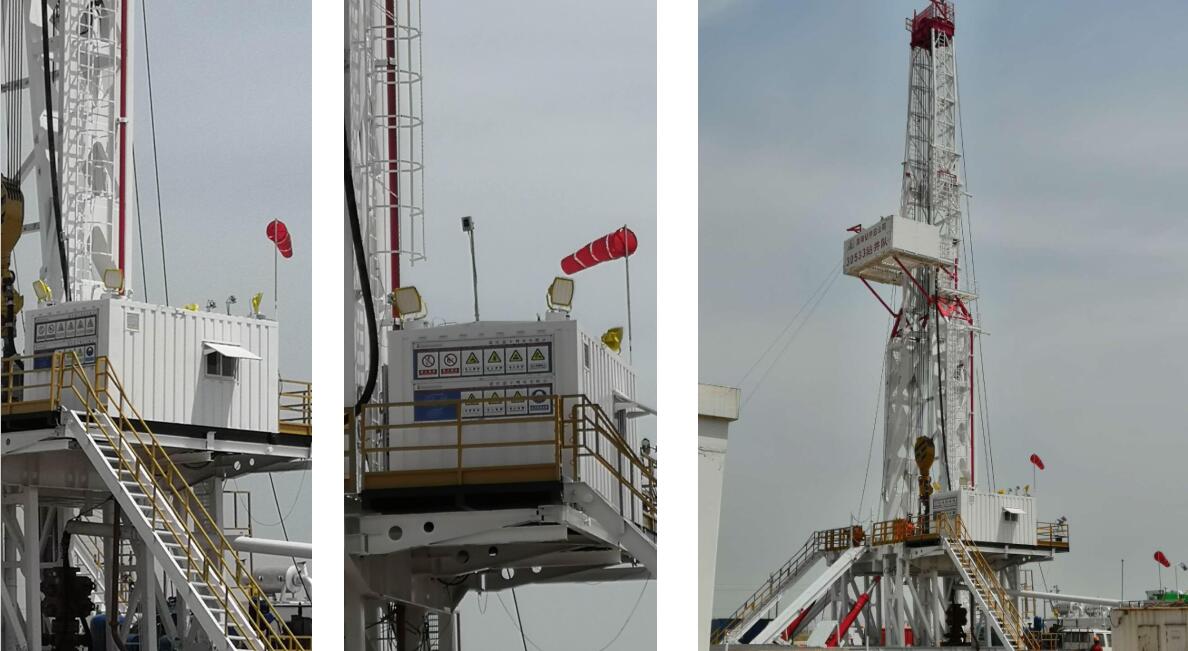

Lighting Requirements for Offshore Drilling Rig Platforms

The lighting system is one of the branches of the power system of the offshore platform, which is directly related to the safety production of the platform and the quality of life of the staff. This paper briefly introduces the selection, installation method, lighting arrangement, system power supply requirements and control of the lighting system of the offshore platform.

CESP LED Explosion proof Lights for Drilling Platform

Part.1 How to select lighting fixtures for offshore platform

The protection level and explosion-proof level of the lamp housing shall be suitable for the installation site and shall meet the following requirements:

The minimum requirements for the protection level of indoor dry spaces should meet IP23;

- The minimum requirements for indoor large dripping spaces and mechanical damage hazard spaces shall meet IP34;

- The minimum requirements for ballast pump rooms, refrigerated rooms, galleys and laundry rooms should meet IP44;

- The minimum protection level for outdoor and open decks should meet IP55.

- When it is in the open air or exposed to rain and waves, the minimum protection level should meet IP56.

Positive pressure ventilation (Exp), flameproof (Ex d) and intrinsically safe (Ex "ia" or "ib") are available in Class 1 hazardous areas. Increased safety (Ex e), positive pressure ventilation (Exp), flameproof (Ex d) and intrinsically safe (Ex "ia" or "ib") are available in Class 2 hazardous areas.

Some marine lighting fixtures and explosion proof lights from CESP for you reference. or you can send the project requirement to us directly.

Part. 2 The type of lighting fixtures and installation

The types of lighting fixtures for offshore platforms can be divided into: fluorescent lamps, high pressure sodium lamps, metal halide lamps, emergency exit lamps, aircraft deck boundary lamps, windsock lamps, etc. Each type of lamps is used in different locations. The following mainly introduces fluorescent lamps and high pressure sodium lamps. , the installation of emergency exit lights.

- Fluorescent lamps: embedded, pole-mounted, wall-mounted, ceiling-mounted, etc.; embedded spaces are used for indoor spaces with ceilings. The pole-mounted type is installed on the boundary of the platform, the wall-mounted type is installed on the firewall, and the hoisting type is installed in the indoor mechanical space.

- High pressure sodium lamp: The high pressure sodium lamp on the platform is divided into flood light and flood light. The flood light is installed on the platform column with a height of 5.5~6 meters. The flood light mainly illuminates the interior of the platform. The floodlight should ensure that its movable part is within the illumination range required by the work, and the rotation is flexible and unobstructed, and the light is not obstructed. Flood lights are also installed on the border of the platform, mainly illuminating the sea surface.

- The emergency exit light is the light fixture of the emergency lighting system. Installed at the door of the room, it is used to indicate the escape route and indicate the rapid evacuation of personnel.

Part.3 Illumination requirements for lighting fixtures

The number and location of lamps in each area depends on the average illuminance of the room. Different areas and rooms have different illuminance requirements. The average illuminance of each area on the platform is as follows:

|

Area |

Normal lighting (average illuminance) |

|

Staircase/passage area |

100 Lux |

|

Restrooms/toilets/changing rooms/other areas |

100 Lux |

|

material storage area |

100 Lux |

|

occupancy cabin |

150 Lux |

|

machinery spaces |

150 Lux |

|

Dining Room/Infirmary/Office/Control Room/Telegraph Room |

200 Lux |

|

kitchen |

300 Lux |

|

Frequency conversion room/electrician room/distribution room |

300 Lux |

Part.4 The layout of lighting fixtures

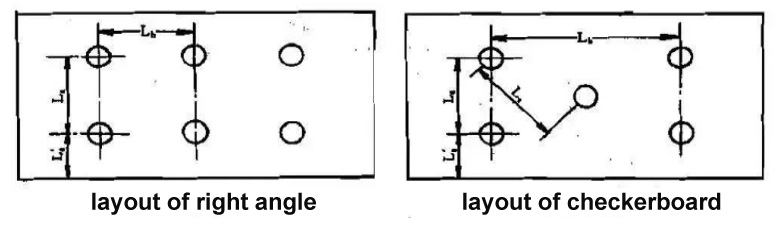

On the basis of the selected lighting fixture model, power and quantity, the cabin lighting fixtures can be arranged. While arranging, the environmental conditions of the cabin should be fully considered, and the main body should be illuminated evenly if possible. Due to the limited space in the cabin, in addition to lighting fixtures, there may be air conditioning vents, fire detectors, speakers, etc. on the ceiling. Therefore, the arrangement of lamps and lanterns must be carefully coordinated with the relevant professions. Make the lighting reasonable, beautiful and applicable as much as possible. When there is only one light in the cabin, it is generally arranged in the center, or close to the working position, and avoid placing it above the bed or in a position that may be severely blocked; when there are two or more lights in the cabin, it is In order to make the lighting of the whole room uniform, and considering the appearance of the cabin, the layout is often symmetrical. The arrangement of multiple lamps can be arranged in a right-angle or checkerboard arrangement as shown in the following figure:

The layout of other areas of the platform lighting fixtures should pay attention to the following aspects:

- It should be ensured that there is sufficient lighting in places where frequent operations and maintenance are required.

- The escape route, emergency escape and fire fighting equipment and other premises must have emergency temporary lighting.

- The arrangement and installation position and height of the lamps should ensure that the lamps are easy to operate and maintain, avoid being arranged above the movable equipment, and do not affect the aisles and safety passages, and provide lighting for the platform to the maximum extent; lamps should not be arranged in the pipeline method. To avoid the gasket breaking and the medium in the pipe spraying to the lamp.

- Emergency lighting should be arranged in the emergency equipment area so that the operation and maintenance of emergency equipment will not be affected when the emergency generator supplies power.

- The light of the lamp is not affected by any obstacles.

- The aircraft deck boundary lights and windsock lights shall ensure the safe take-off and landing of the helicopter on the offshore platform, and the arrangement and installation position shall comply with the relevant.

CESP Case: CNOOC - Oilfield & Offshore Lighting Engineering Project

Part.5 Lighting system power supply and control

Lighting can be divided into: normal lighting system, emergency lighting system, temporary emergency lighting system. The normal lighting switchboard shall not be placed in the same space as the emergency lighting switchboard. Except for personnel living spaces, the emergency light points in other spaces of the platform should be higher than at least 1/3 of the total number of light points in the room. Each lighting circuit shall be provided with overload and short circuit protection. Each lighting switchboard with a capacity greater than 16A should have no more than one last shunt power supply lamp.

The number of points of the last shunt-supplied lamps with a capacity less than or equal to 16A shall not exceed:

For circuits of 50V and below: 10 points

For 51~120V circuit: 14 points

For 121~250V circuit: 24 points

The power supply lamp head is close to the final shunt of the clustered cornice lighting, wall lamps, electric signs, etc. If the maximum working current does not exceed 10A, the lamp points supplied can be unlimited. The last branch of the lighting circuit should not supply power to electric heating and electrical equipment, but for small kitchen equipment (such as bread toasters, small mixers, coffee pots), small electric motors (such as desk fans, cabin fans, refrigerators) ), wardrobe heaters and the like may be excluded. For large machinery spaces, large galleys, passages (including entrances and exits), stairways leading to lifeboat decks and public spaces, the lighting is to be powered by at least two final branches for lighting. When any one of the routes is not powered, the other route should still be able to maintain the above necessary lighting.

The lighting system of the offshore platform directly affects the overall quality of the platform, so the lighting design must not only be meticulous, but also pay attention to methods, make overall arrangements, and follow specifications.

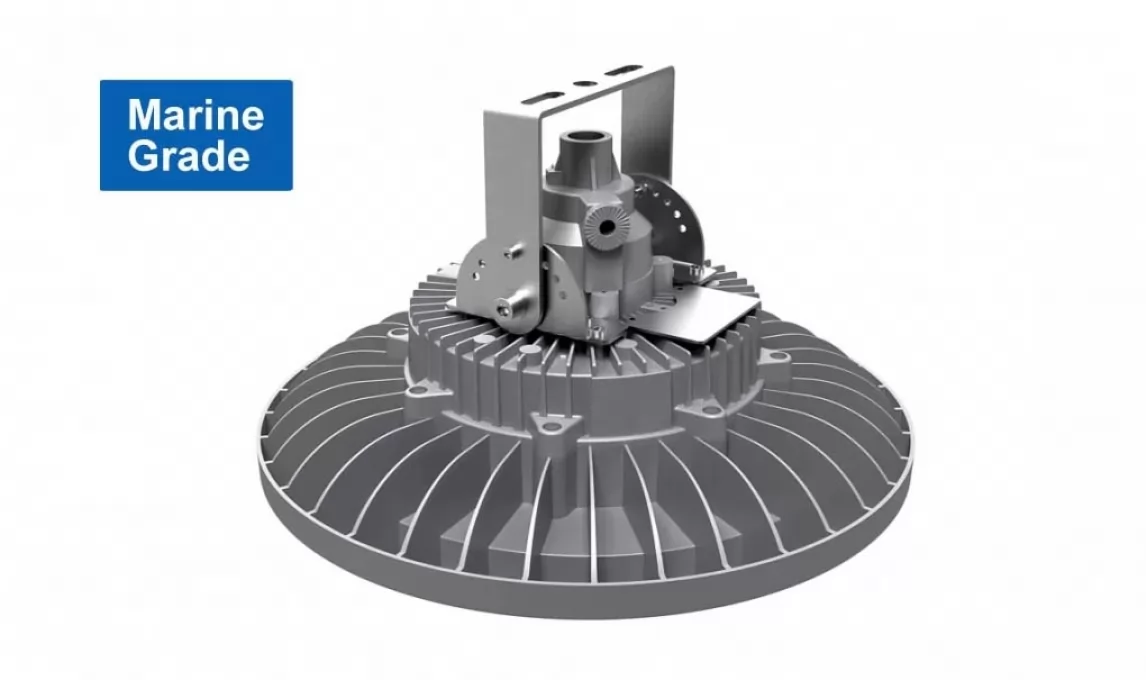

Marine Lighting - Explosion Proof Floodlight - Class 1 Division 2 - 40W to 200W

Marine Grade Explosion proof LED Flood Light | Class 1 Division 2 Light | Anti-Corrosion

In accordance with UL1598A requirements, the lamp body of CESP marine-grade LED lighting fixtures is coated with multiple layers of marine-grade anti-corrosion paint. Additionally, the mounting brackets and accessories are made of 316 stainless steel to ensure long-term reliability in harsh saltwater and atmospheric corrosion environments. Furthermore, the product includes a UL844 certification, making it suitable for Class 1 Division 2 hazardous location lighting.

Application:

• Applies to hazardous locations of Class I, Division 2 with explosive gas atmosphere.

• Applies to marine locations, non-recessed outside type (salt water).

Warning:

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING 40°C;

- FOR SUPPLY CONNECTION, USE WIRES RATED FOR AT LEAST90°C;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

UL for marine locations:

- OUTSIDE TYPE or OUTSIDE TYPE (SALT WATER);

Features

- Industry-leading efficacy: up to 140 LM/W

- -40°C to +55°C Ambient operating temperature

- Wide optics for uniform illumination

- Fixture warranty

- Entry Size: NPT 3/4”-14 ;

- Housing –Aluminum alloy (ADC12 ) - Anti-corrosion powder coating

- Lens –tempered glass

- Beam angle: 108°, 120°

- Dimension: 300x300x165mm

- Weight: 7.5kg

Parameters

- Power: 40W / 60W/ 80W/ 100W/120W/ 150W/ 185W / 200W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 110 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: Meanwell HLG series

Ex Standard (UL844, UL1598)

Have certified CES-J fixtures with the NEC and CEC standards for hazardous location and environments

- Class I, Division 2, Groups A, B, C and D

- T-Class: T6

- Damp and wet locations

- Certificate No:E475887

- US: UL 844; UL 1598A;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0;

Marine Standard (UL1598, UL1598A)

Certifications and compliancesfor marine locations:

• Damp and wet locations;

• Certification body:UL

• Certification Mark:UL

• Certificate No:E495071