IECEx ATEX Certified Explosion proof LED Lights - Zone 1 Zone 2 Hazardous Area Lighting

For Zone 1 Zone 2, Zone 21 Zone 22 hazardous area led lighting, 20W - 200W, 130lm/W,aluminum alloy + 8mm tempered glass, multi-installation for different projects, such as light tower, canopy light, marine grade.

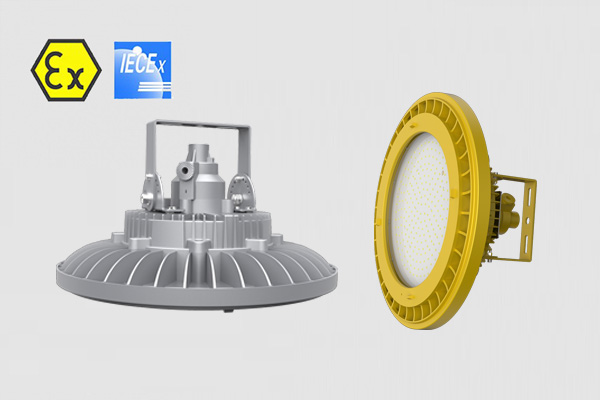

Flameproof enclosure, Ex db op is IIC T6 Gb, Zone 1 & Zone 21 with explosive gas atmosphere, Zone 21 and Zone22 with explosive dust atmosphere, 10mm temered glass, 7J impact resistance,up to 26000lm.

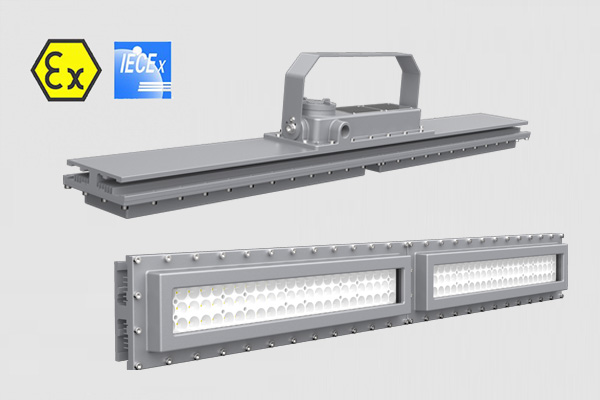

Flameproof enclosure, Ex db op is IIC T6 Gb, IP68 protection grade, tempered glass 10mm, withstand impacts up to 10J, 2 foot and 4 foot Length, 50Watt- 240Watt, 130lm/W light efficacy.

Zone 1 & Zone 21, 1ft, 2ft, 3ft, 4ft length can be selected, replace the traditional explosion-proof three-proof lamp, explosion-proof fluorescent tube, anti-corrosion, anti-glare, anti-drop, competitive price.

Flameproof LED hand lamp for Zone 1 & Zone 21 hazardous areas, 10mm tempered glass, pass the multi-angle drop test, 10W, 20W, 30W Power, can be connected to the cable, emergency power box.

The CES-EX-SF series explosion-proof ceiling lamp has a strong shell, with features such as impact resistance, vibration resistance, and corrosion resistance. It can be used in hazardous environments of Zone 1&21, Zone 2&22.

CES-EX-JX Series is your go-to solution for illuminating hazardous Zone 1 and Zone 21 areas. With ATEX approval, these Explosion-proof LED Flood Lights offer unbeatable safety standards.

Discover the pinnacle of safety and illumination with our CES-EX-GBX Series Explosion-proof LED High Bay Lights. Designed for hazardous Zone 1 and Zone 21 areas, these lights boast ATEX approval, ensuring the highest safety standards.

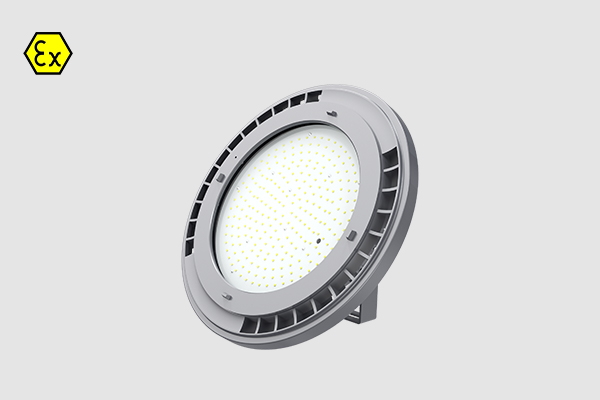

GB-02 explosion-proof lights are made of alloy aluminum and tempered glass, with shock resistance and anti-vibration performance. The luminaires have passed the ATEX IECEx standards test, from 30W to 80W for hazardous area lighting.

LN-02 explosion-proof lights obtained an IECEx ATEX certificate, it's safe for the Zone 1 and Zone 2 hazardous locations. The copper-free aluminum alloy body is powder-coated to increase durability and beautiful appearance, are able to withstand violent shaking and shock resistance.

an innovative line of LED hazardous area lighting products, specifically designed for use in potentially explosive atmospheres (Zone 1/21 & 2/22) within harsh industrial settings such as coal mines and oil & gas facilities.

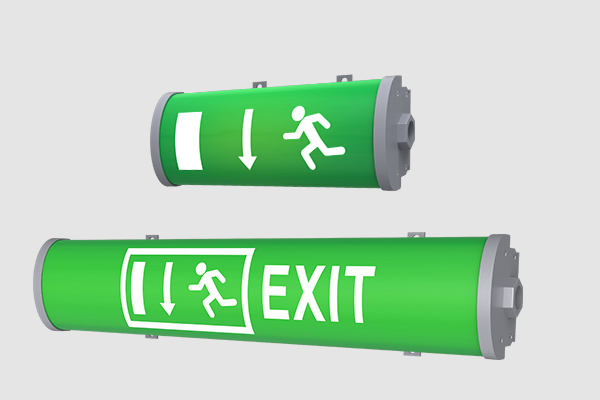

Explosion-proof safety exit lamps are for personnel evacuation, and fire operations to provide lighting fire emergency lamps! It usually uses an external power supply, when the power automatically switches to the battery power state!

Coal Mine Lighting Solution

The coal mine is a special lighting place, without natural light, and underground work is relatively dependent on lighting. Traditional coal mine lighting (incandescent, fluorescent, high-pressure sodium, etc.) has poor light penetration, short light life, and frequent maintenance. insufficient.

The LED light source is a cold light source, which has the advantages of high luminous efficiency, long life, energy saving and environmental protection. In recent years, in combination with the coal mine lighting environment and use requirements, the LED mining lamps developed and developed can withstand and resist shocks in underground lighting. , Anti-vibration, strong light penetration, less heat, power saving, long life, less maintenance, has gradually become the mainstream product of the new generation of coal mine lighting.

- The application of LED in coal mine lighting

Coal mine lighting is generally divided into mine ground lighting and underground lighting, while underground lighting can be divided into portable mobile lighting, roadway lighting, chamber lighting, airborne lighting, mining face lighting, etc. Due to the different underground environment and use requirements, LED mining According to the "GB3836-2010 Explosive Environment" series of standards, the lamps can be divided into flameproof enclosure type, intrinsic safety type, flameproof enclosure and intrinsic safety type, etc., according to "Coal Mine Safety Regulations", "Complete Standards for Coal Mine Mechanical and Electrical Equipment", "National Explosion-proof Electrical Standards, etc., can also be divided into the following common types:

- Miner's lamp

The miner’s light is a portable mobile lighting in underground lighting. Compared with the traditional miner’s lamp, the LED miner’s lamp is characterized by: overall sealed and explosion-proof design; high-power LED lamp beads have a maximum temperature of only 60℃, large-capacity lithium manganate battery, with overcharge and overdischarge Protection; intrinsic safety circuit with electronic short circuit protection design. Common specifications are: LED miner's lamp (4Ah, 5Ah), LED methane alarm miner's lamp (4Ah, 5Ah, 6Ah), etc.

- Laneway lights

Roadway lights are used and maintained the most in underground lighting. Compared with traditional roadway lights (straight tube fluorescent lamps and high-pressure sodium lamps), LED roadway lights have good sealing performance, good heat resistance, impact resistance, and a variety of circuit protections. The voltage effect is small, the light source is stable, the average illuminance is large, the light penetration is strong, the life is long, maintenance-free, the number of lamp changes are reduced, and the energy saving and environmental protection are characteristics. Common specifications are (in W): flameproof type (10, 12, 15, 18, 26, 30, 36, 40, 50, 55, 60, 70, 90, 100, 110, 120, 200, 24W), Intrinsically safe type (5, 8, 12, 13, 16, 21), flameproof and intrinsically safe type (12, 15, 18, 20, 24, 30, 36, 40, 48, 60, 80, 90, 108) Wait.

- Signal light

Signal lights are suitable for underground roadway safety instructions. Compared with traditional signal lights (high pressure sodium lamps), LED signal lights have the characteristics of high light efficiency, high color rendering index, long life, less maintenance, energy saving and environmental protection. 15W, 60W, 18W), flameproof and intrinsically safe type (5W).

- Locomotive lights

With the application of fully mechanized mining technology in modern coal mines, the application of LED locomotive lights on electric locomotives, explosion-proof vehicles, roadheaders, loader trucks, and coal shovels is also increasing. Compared with traditional incandescent lamps, LED locomotive lights have the following characteristics: LED light source has strong shock resistance, high luminous efficiency, safety and reliability, energy saving, and long service life. Common specifications are: flameproof type (9W, 12W, 15W, 18W, 20W) , 24W), intrinsically safe type (24W), etc.

- Bracket light

Compared with traditional stent lights (double-tube high-pressure sodium lamps), LED stent lights are suitable for underground fully mechanized mining face. Its characteristics are: intrinsically safe circuits, with over-current and over-voltage protection, short-circuit protection, LED high-brightness light source, and lighting life. Long; good sealing performance, water vapor, corrosion resistance, strong impact resistance, strong vibration, explosion-proof; maintenance-free, convenient installation and debugging, energy saving and environmental protection, common specifications are: flameproof enclosure and intrinsic safety (20W, 24W. 48W, 36W) , flameproof enclosure type (16W. 18W), etc.

- Design of LED mining lamps

At present, there are many units engaged in the development and design of LED mining lamps, and the representative ones are: Shenyang Guangjiao Complete Electric Co., Ltd., Huarong Technology Co., Ltd., Shenzhen Cesp Co.,Ltd, and Jiaozuo Jingan Electromechanical Equipment Manufacturing Co., Ltd., Coal Science and Technology Research Institute Co., Ltd., China Coal Science and Industry Group Chongqing Research Institute Co., Ltd., Hengshui Puguang Lighting Technology Development Co., Ltd., Zhejiang Xusheng Lighting Co., Ltd., Linfen Huace Xinguangyu Power Co., Ltd., Yueqing Sanle Lighting Co., Ltd., Nanjing Jingruida Lighting Manufacturing Co., Ltd., etc.

LED mining lamps require an MA certificate before they can be used in underground lighting. The design standard is mainly based on the "3836-2010 Explosive Gas" series. The procedures for applying for the MA mark are usually: safety standard center (online filing, drawing review), explosion-proof station (sample inspection), and production enterprise (on-site review).

The explosion-proof stations for testing and inspecting LED mining lamps mainly include: National Safety Production Fushun Mining Equipment Inspection and Inspection Center, Shanghai Mining Equipment Inspection and Inspection Center, Chongqing Mining Equipment Inspection and Inspection Center, Nanyang Explosion-proof Electrical Inspection and Inspection Center, Jiamusi Explosion-proof Electrical Inspection Inspection Center, Shenyang Explosion-proof Electrical Inspection and Inspection Center.

In the development and design process, the more concerned contents include: the selection of explosion-proof materials (housing, transparent parts, sealing rings, LED light source components), the design of the explosion-proof structure of the whole lamp (refer to the national standard, the industrial standard), and the drive circuit (intrinsic safe) Type) and a variety of circuit protection designs, LED luminous flux and heat dissipation (reducing the impact on LED light efficiency and life), optimized light distribution (secondary light distribution, achieving uniform illumination, reducing stroboscopic and light decay), etc.

A qualified LED mining lamp needs to perform the following tests (take 24W flameproof LED roadway lamp as an example).

① Prototype inspection, with "GB3836-2010 Explosive Gas" series as standard inspection drawings.

② Shell pressure test (static pressure method,), the sample is subjected to a 1000KPa shell static pressure test once. For example, the pressure time is at least 10S, and it should not be deformed, damaged or leaked.

③ Shell impact resistance test, room temperature 20±5℃, the impact direction should be perpendicular to the tested surface, and should not be broken after being impacted by a weight of 1Kg with a drop height of 2.0m.

④ Thermal fusion test, when the transparent part or glass is at the highest working temperature, it should not be broken when sprayed with water of 1m in diameter at 10±5℃.

⑤ Voltage passive test, when the power supply voltage fluctuates within the range of 75%-110% of the rated voltage, the lamp should be able to light up.

⑥ Illumination test, 3m, ≥ 10lx.

⑦ Surface temperature measurement,≤150℃,

⑧ Dielectric strength test, voltage 2.OKV, there should be no breakdown or flicker after 1min.

⑨ Insulation resistance test, ≥20.0MΩ.

In addition, there are some internally ignited non-detonation tests, introduction device clamping and sealing tests, transparent parts impact resistance test, heat resistance, cold resistance test, visual inspection, humidity and heat resistance, vibration test, impact test and other tests.

The current selection principles of underground lighting fixtures are: high luminous efficiency, high CRI, long life, explosion-proof, high cost performance, and low maintenance. LED mining lamps cater to these principles and meet the needs of old mine reconstruction and new mine construction. With the promotion of national energy saving and emission reduction, green lighting policies, and the upgrading and optimization of LED mining lamps in material selection, explosion-proof design, LED light source, and power drive design, high-performance LED mining lamps will provide powerful lighting for coal mines. Guaranteed.

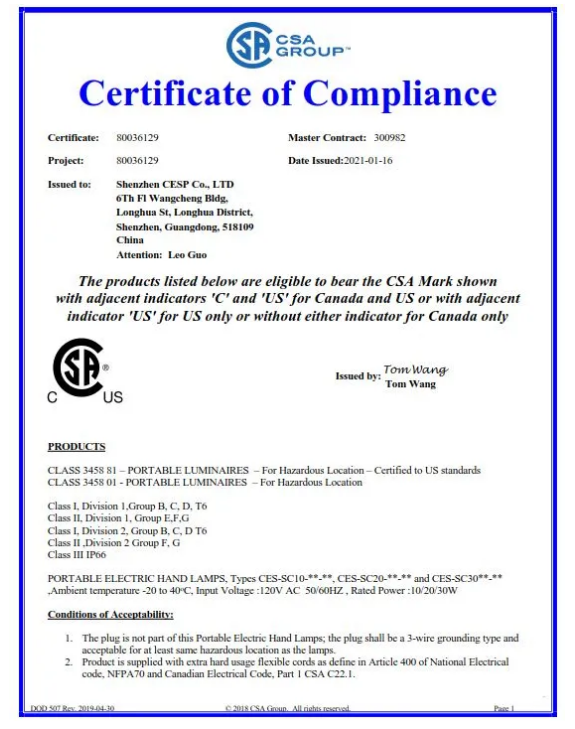

CESP is a state-level high-tech enterprise and a contract energy management company that has been filed by the three ministries and commissions. CESP strive to high quality patent product in military & industry areas, is the Top OEM & ODM supplier for explosion proof lighting solution of China and the 1st Company in China to be certify for hazardous location led lighting fixture by UL & CUL. In December 2020, CSA Group issued UL844 and CSA 137 standard explosion proof certificate (Division 1) for CES-SC series, that means that CESP has made another big progress in the field of explosion-proof lighting.

The SC series explosion proof LED hand lamp uses high-strength VO-grade rubber handles and ADC12 aluminum alloy material, with low-carbon steel wire, which can effectively reduce the weight of the lamp body and improve durability. The outer glass adopts high-strength tempered glass, which has passed internal pressure, hydraulic pressure and other tests, and its corrosion resistance reaches WF2, IP grade IP67, and can withstand 7 J pressure. The lamp beads made of high-quality LM80 certified chips have a luminous efficiency of up to 130 LM\W. For example, a 30W explosion-proof LED work light can produce 3900 LM, 180° or 360° luminous angles to meet all-round lighting. In general, the LED explosion-proof hand light is beautiful and simple in appearance, and convenient to operate, can be hand-held, placed on a table, magnetically attracted, and suspended for lighting. As the explosion-proof hand light is very light and small, it can provide portable lighting for hazardous locations and temporary projects. It is very suitable for close work and inspection activities in hazardous areas where require explosion protection, such as quick plant turnarounds, MRO projects, oil fields, marine sites and tank cleaning etc.

If you want to know more details about this lamp, you can click here to view it. The following are some simple parameters of Ex-proof LED handlamp.

|

CES-SC |

CES-EX-SC |

|

|

Input voltage |

120Vac |

AC100V-277V/DC110V/DC12V-24V |

|

Power |

30W/20W/10W |

|

|

LEDs Chip |

72Pcs 3030 |

|

|

Beam angle |

360°/180° |

|

|

dimension |

Φ101.5 x 517mm |

Φ101.5 x 516.5 mm |

|

Light efficiency |

>130 lm/W |

|

|

CRI |

70 |

|

|

CCT |

3000K-6500K |

|

|

Protective net structure |

Full net top hook/half net |

Full net top hook / half net / full net side hook |

|

Lamp body material |

ADC12 |

|

|

Protective net material |

Low carbon steel wire-electroplating |

|

|

handle |

V0 grade plastic handle |

ADC12 shell, outsourcing V0 grade rubber handle |

|

Terminals |

Push-in type crimping terminal |

Bolt compression terminal |

|

Granto |

/ |

M20X1.5(ATEX) |

|

cable |

STW , UL, 3x18AWG |

Three-core rubber cable, IEC(CE) |

|

Transparent pieces |

Tempered glass (thickness 10mm) |

|

|

Nameplate installation method |

Stainless steel (rivet) |

|

|

applied area |

C1D1/C2D1/C1D2/C2D2/C3 |

Zone1/21/2/22 |

The coal mine is a special lighting place, there is no natural light, and underground work depends more on lighting. Conventional coal mine lighting fixtures (incandescent lamps, fluorescent lamps, high-pressure sodium lamps, etc.) have low light transmittance, short lighting life and long maintenance time. Mine lighting is generally divided into ground lighting and underground lighting. Underground lighting can be divided into portable lighting, tunnel lighting, cave lighting, vehicle lighting, mining face lighting, etc. According to "GB3836-2010 Explosive Environment Series Standards", due to the different underground environment and usage requirements, LED mining lamps are divided into fireproof, intrinsically safe, fireproof and intrinsically safe. According to "Coal Mine Safety Regulations", "Comprehensive Standards for Coal Mine Mechanical and Electrical Equipment", "International Explosion-proof Electrical Standards", etc., CESP has developed LED explosion-proof miner's lamps, LED explosion-proof hand lamps, LED explosion-proof floodlights, and LED explosion-proof emergency lights suitable for underground lighting. And various explosion-proof plugs, it has the advantages of full sealing, high temperature resistance, impact resistance and vibration resistance. Multi-channel protection function, small impact on voltage, high luminous efficiency, stable light source, large average illuminance, and strong light penetration. The invention has the characteristics of strong shock resistance, safety, reliability, energy saving, and long service life, and at the same time saves manpower, electricity and other costs.

The first Class 1 Division 1 Hazardous Location LED hand lamp are officially launched

Recently, Shenzhen CESP Co., Ltd. (hereinafter referred to as: CESP) Hazardous Location LED hand light CES-SC series passed Division 1 and Division 2 (CSA 137 and UL 844 standards) explosion-proof certification of North American, and on January 27 held a certification ceremony in Kunshan Lab of CSA Group, which marked another major breakthrough of CESP in the field of global explosion protection.

Representatives attending this certification ceremony include Jiyi Guo, Deputy General Manager of CESP, Wu Wei, Commercial Director of CSA Group China, Zeng Hong, Explosion-Proof and Industrial Division Manager of CSA Group, and Wang Yongxi , Explosion-proof Equipment Technical Expert of CSA Group, etc.

At the ceremony, Wu Wei, China Commercial Director of CSA Group, issued a certificate to Guo Jiyi, Deputy General Manager of CESP.

The training, evaluation, testing and certification of UL 844 and CSA 137 standards involved in this certification are all completed by the CSA China team. As the first full-explosion-proof certificate to be completed by the CSA certification body in its local laboratory in China. CESP and the CSA China team conducted full and direct communication in advance for possible problems in the evaluation and test details, so as to formulate an optimized project test plan. During the testing process, CSA China's full-process localized professional and efficient services ensured the smooth completion of the entire project.

Obtaining the certificate indicates that the related products of CES-SC series have met the requirements of the Division system UL 844 and CSA C22.2 No. 137 of the United States and Canada, and cover all explosion-proof grades, that is, Class I Division 1, Class I Division 2, Class II Division 1, Class II Division 2, Class III, IP66, and reach the highest temperature class T6, so it will have a great application in hazardous locations in North America. After obtaining the certificate, CESP obtained orders from North American customers for the first time, and the product quickly entered the target market.

View detailsHazardous Location Led Hand Light

As a global explosion-proof lighting equipment manufacturer, since its establishment in 2007, CESP Southern has focused on providing customers with high-quality hazardous area lighting products. All products are strictly in accordance with the North American "UL844 explosion-proof certification", "EU ATEX certification", "International IECEx Explosion-proof Certification", "China GB 3836 Explosion-proof Certification" standard design, and obtained relevant explosion-proof certificates.

Over the years, we have worked closely with well-known international companies, with projects covering many countries around the world, among which classic projects include the U.S. Navy aircraft carrier, Canadian oilfields, Qatar oilfields, Shell oil stations, etc.. In China, CESP is a subsidiary of CNPC, Sinopec, CNOOC, China Coal’s cooperative suppliers have provided explosion-proof lighting products for many gas stations, oil refineries, offshore platforms, and coal mining plants. After years of precipitation, the "CESP" brand enjoys a high reputation in the international explosion-proof lighting field.

CSA Group was established in 1919 and is an internationally recognized authority in standard development, testing and certification. CSA Group's business scope covers alternative new energy, medical equipment, hazardous locations, industry, sanitary ware, construction, safety and technology, electrical appliances, gas, lighting and sustainable development, as well as consumer product evaluation services. As one of the world’s largest standard setting organizations (SDO), CSA Group is the main setter of many standards in the United States and Canada. Over the years, many standards formulated by CSA Group have been adopted in the national standards of Canada and the United States. Efforts and contributions have been made to the safety, stability and sustainable development of society. The services of CSA Group are trusted by many top brands in the world and are widely recognized by many organizations around the world. Billions of products around the world are adopting the CSA logo. For more information about CSA Group, please visit www.csagroup.org

CESP was established in 2007 with Register Capital of 50 Millions RMB, Office Area of 2000 M2, Manufacturing Facility of 18036 M2 , now 200+ employees. Our R&D center has an international UL-authorized witness laboratory and is a state-authorized special military equipment manufacturing enterprise and State High-tech Enterprises.

If you need Hazardous Location Led Hand Light for Zone 1 & 21, please click here: Explosion Proof LED Drop Light

Explosion proof LED High Bay Light CES-EX-GB

Emergency Lighting Fixtures - Container project in United Arab Emirates

CESP LED Explosion Proof Flood Lights & Explosion Proof Exit Sign Light for Container project, This Case in United Arab Emirates.

Chemical Plants Lighting Solution

As the production base for crude oil cracking, chemical plants are mostly explosion-proof areas in Zone 1 and Zone 2.

From heavy oil separation to light oil undergoing catalytic cracking process, it is necessary to press and press into various organic branch components to participate in the reaction.

In the production process, the explosion-proof motor is used to drive the pressure pump, and various ingredients participating in the reaction are added.

At a certain temperature, crude oil will be cracked into various light-density oils and organic gas-like substances. These factories are to work without interruption for 24 hours. so explosion-proof lights are a necessary condition for lighting in production workshops and pressure vessels.

In addition, the outdoor area of chemical plants requires good waterproof and corrosion resistance. At the same time, most of them are a few meters or hundreds of meters in high altitude areas, high temperature and high pressure, the lamp sreplacement and maintenance are extremely difficult. Therefore, the use of lamps in chemical plants is not just for lighting, but more emphasis on safety and reliability.

CESP's explosion-proof led lights designed for chemical plants are strictly compliant with UL, CUL, DLC, IECEX, ATEX, and EX standards in terms of technology and lighting, and the protection class is IP68 to meet our customers requirement.

Ex Lighting for Gas Boiler

Do you know what’s the notice in gas boiler explosion-proof lighting and other Explosion-proof equipment design?

With the increasing efforts of national environmental pollution control and energy structure adjustment, the proportion of gas boiler houses is increasing in the construction of boiler houses.

With the increasing efforts of national environmental pollution control and energy structure adjustment, the proportion of gas boiler houses is increasing in the construction of boiler houses. The gas boiler room uses natural gas as fuel, and natural gas is a flammable and explosive gas. Therefore, the design of the gas boiler room pays special attention to safety issues. The electrical equipment in the boiler room is mostly equipped with explosion-proof.

Over time, people can easily form a fixed thinking, the boiler room belongs to the hazardous areas, and should be designed according to explosion proof standard.

Actually, this is a misunderstanding in our judgment.

We cannot simply determine that this area is an hazardous area because of the existence of flammable and explosive gases in a certain area. Instead, it should be considered in combination with the process production process and fire risk classification of the area. If the area is indeed an explosion hazardous area, the area of the explosive gas environment should be classified according to the provisions of the “Explosion Regulations” and the range of the area should be determined. Then, according to the type of the hazardous area of the explosive gas environment, corresponding explosion-proof design measures should be taken, such as "Explosion Hazardous Environment Power Device Design Specification", and different country have different standard and requirement.

Electrical design and electrical equipment selection for gas boilers

The boiler body in the boiler room, the electric control box of the boiler, and the electrical instruments on the boiler are all common equipment, not explosion-proof electrical equipment. There is no any sense to require only the electrical professional to use explosion-proof electrical equipment. For example, GB 50041 - 2008 "Boiler House Design Code" does not stipulate that the electrical profession must be designed in accordance with the requirements of explosion protection. It just asks for electrical design are as follows:

The choice of motor, start-up control equipment, luminaires and conductor types should be compatible with the environmental classification of the different buildings and structures in the boiler room.

The classification of explosion and fire hazard sites in boilers, gas pressure control rooms, fuel pump rooms, pulverized coal preparation rooms, coal crushers rooms and coal transportation corridors of fuel and gas boiler rooms must comply with the national standards. Relevant provisions for environmental power device design specifications.

The provisions are as follows,

In the gas, if the main component of natural gas is methane, it is easy to catch fire when it forms a mixed gas with 5% to 15% concentration of air. Therefore, the natural gas pressure regulating room belongs to explosion-proof buildings... Buildings and structures in different environments The selected motor and electrical equipment should be compatible with the different environments.

It can be seen that the selection of electrical equipment is compatible with the environmental classification of buildings and structures, and the selection requirements for electrical equipment in Class A and Ding production plants are quite different.

The determination of the explosion hazardous area in the production plant shall not deviate from the process characteristics and production process, and shall not deviate from the qualitative nature of the building. If these factors are not taken into account, the room shall be declared explosive according to the provisions of the "Explosion Regulations". the design of electric power in an explosive gas environment is a joke.

For example, the kitchen using natural gas and liquefied gas is in full compliance with the "explosion regulations", but no one will be electrically designed according to the explosive gas environment, nor will the kitchen appliances be used for explosion-proof products. The gas design code has clearly pointed out that the boiler room and the water heater room are non-explosive hazardous places, so it is not unreasonable to select electrical equipment according to the normal environment.

When carrying out the electrical design of the gas boiler room, the boiler room should be classified according to the production characteristics and production process of each room, combined with the fire hazard level of the plant to determine which rooms belong to the hazardous areas of explosion, and then according to the provisions of the “Explosion Regulations”. Partition the hazardous area and determine the extent of the partition, then take appropriate explosion-proof design measures.

For example, in the gas inlet room, it is a Class A production room and belongs to Zone 2 of the explosive gas hazardous environment. Equipment selection should be carried out according to the requirements of Zone 2. The boiler room is a Ding production room, which is not an explosion hazardous area and can be electrically designed according to the normal environment. Generally speaking, when a valve appears in a gas boiler room, the valve is equivalent to a release source, and the explosion source is within a certain range of the release source within a certain range, and electrical equipment should be avoided in the area.

However, in most cases, the valves are placed close to the boiler body. The actual design of the boiler body, boiler electrical control box, and electrical instruments on the boiler are common equipment, and many gas design standards also indicate These places in the boiler room and the water heater room are non-explosive hazardous areas, which is also the reason why the boiler room is characterized as a D-type production room. If it is considered that the entire boiler room is an explosion hazardous area and is designated as an explosive gas environment zone 2, it is inconsistent with the regulations on the risk of fire in the boiler room.

Other safety measures for electrical design of gas boilers

As mentioned earlier, there is no basis for setting the boiler room as an explosion hazard area.

Of course, in order to ensure the operation and maintenance safety of the boiler, we must take some safety measures, such as setting the flammable gas concentration alarm device, accident exhaust device, and pipeline for anti-static grounding. In some administrative regulations, explosion-proof luminaires are required in the boiler room. These additional requirements should also be followed by the designer. This is equivalent to raising the design standards (although there is no substantial effect on safety) and the explosion between the boiler and the boiler. The explosion protection measures that must be taken in the area are two distinct concepts.

In addition, the accidental fan of the gas boiler room must be explosion-proof. This is reasonable and necessary, because the accident fan is not characterized according to its installation area, but is characterized according to the nature of its work. It is an accident in which the concentration of flammable gas exceeds the standard. In order to work, an explosion-proof motor must be used to ensure safety. Even if the accident fan is placed in the open environment of the roof, an explosion-proof fan is still required.

From the controversy over the electrical design of the gas boiler room, it is clear that people attaches great importance to the safety of gas use, which is a good thing. However, it is not enough to pay attention to it. It is also necessary to understand the dangerous factors of gas in various environments.

For example, the danger of the gas boiler house during the outage period is often higher than during the operation period. During the shutdown of the boiler, the residual gas in the furnace will pose a safety hazard. Therefore, the furnace must be cleaned with compressed air before the furnace is repaired. In order to carry out open fire operations. Of course, the safety of boiler maintenance has a strict set of operating procedures, which is no longer within the scope of electrical design.

At present, some electrical designers who have met the gas pipeline, regardless of the location, and whether the valve is installed on the gas pipeline, will set the flammable gas concentration alarm device, and the electrical equipment will be changed to explosion-proof type, which will waste money and fail to play. Any security role.

Question about location classification

Not only the gas boiler room, but also the electrical design of other explosive gas environments, it is necessary to combine the process characteristics and production process to classify the site reasonably, and determine the explosion danger zone, the explosive gas environment zone and the zone range. This is a highly specialized and complex job that is closely related to process equipment layout, production processes, raw material/product storage, physical and chemical properties of hazardous releases, and ventilation conditions.

The work of site classification is far from being as simple as some people think, and electrical engineers are not qualified for this job. Each country has a certified safety engineer with comprehensive expertise in process, ventilation, and electrical related fields. The classification of the site, the zoning of the explosive gas environment, and the scope determination are the responsibility of them.

Summary as follow

a. The gas boiler room is not an explosion hazardous area.

b. The boiler body, boiler electric control box and electrical instrument on the boiler in the gas boiler room are common equipment, not explosion-proof electrical equipment. The electrical professional can design and select according to non-explosive hazardous areas.

c. Some places have administrative regulations that require explosion-proof electrical appliances in gas-fired boiler rooms. Electrical design can improve design standards according to this requirement.

d. Accident fans in gas boiler rooms should use explosion-proof motors.

e. If there is no valve on the gas line, it is not necessary to perform electrical design in the hazardous areas where it is exposed.

f. The classification of the explosive gas environment require comprehensive technical expertise in the relevant fields such as process, ventilation and electrical. This work is generally performed by professionals.

CESP provide all kinds of LED explosion proof lighting fixtures for hazardous areas, including gas boiler plant lighting fixture, contact us to ask detail and professional lighting solution for your projects.

Metallurgical Industry Lighting Solution

The goal of the metallurgical industry lighting is to absolutely ensure that metallurgical work can have absolutely good visibility.

The goal of the metallurgical industry lighting is to absolutely ensure that metallurgical work can have absolutely good visibility. The use of professional metallurgical lighting solutions enables the metallurgical industry to work safely in every worker and every region, reduce the incidence of accidents and the incidence of equipment failures, and greatly increase production efficiency.

Metallurgical industry lighting status:

1. Metallurgical lighting systems have low illumination and cannot meet the lighting requirements of the normal operation of the production line;

2. The old high-energy gas discharge light sources cannot achieve the purpose of high efficiency and energy saving of the lamps;

3. The lamps and lanterns are seriously aged, and the waterproof, dustproof and shockproof performances do not exert the best effect;

4. The light of the light source is seriously degraded, dim and non-uniform, causing the illumination of the light fixture to not meet the needs of metallurgical work environment lighting.

Metallurgical industry lighting solutions must consider reducing the safety issues in the metallurgical industry due to lighting in all regions and each worker safe, improve the productivity, and reduce the probability of accidents.

Because the metallurgical industry's production sites mostly have high-temperature, strong vibration, dust, mixed gas and other complex lighting environment. Therefore, in the lighting of the metallurgical industry, a reasonable lighting solution is needed to meet the requirements of its complex lighting production environment. In the metallurgical industry lighting, we generally require that the lamps have a certain degree of explosion-proof. And can meet the requirements of good seismic performance, waterproof and dustproof. The brightness of the luminaire is high, and the life plant can guarantee the safe and reliable illumination mode for the transportation bridge and other areas.