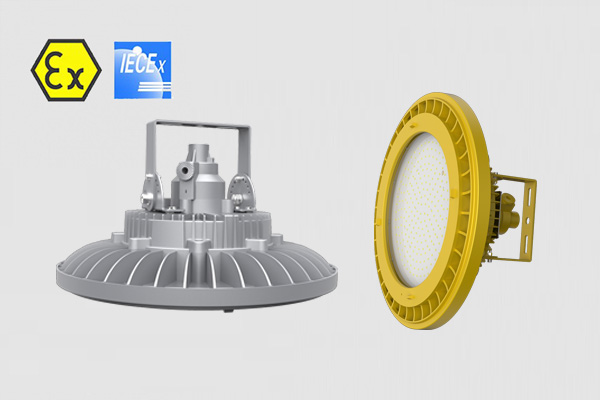

IECEx ATEX Certified Explosion proof LED Lights - Zone 1 Zone 2 Hazardous Area Lighting

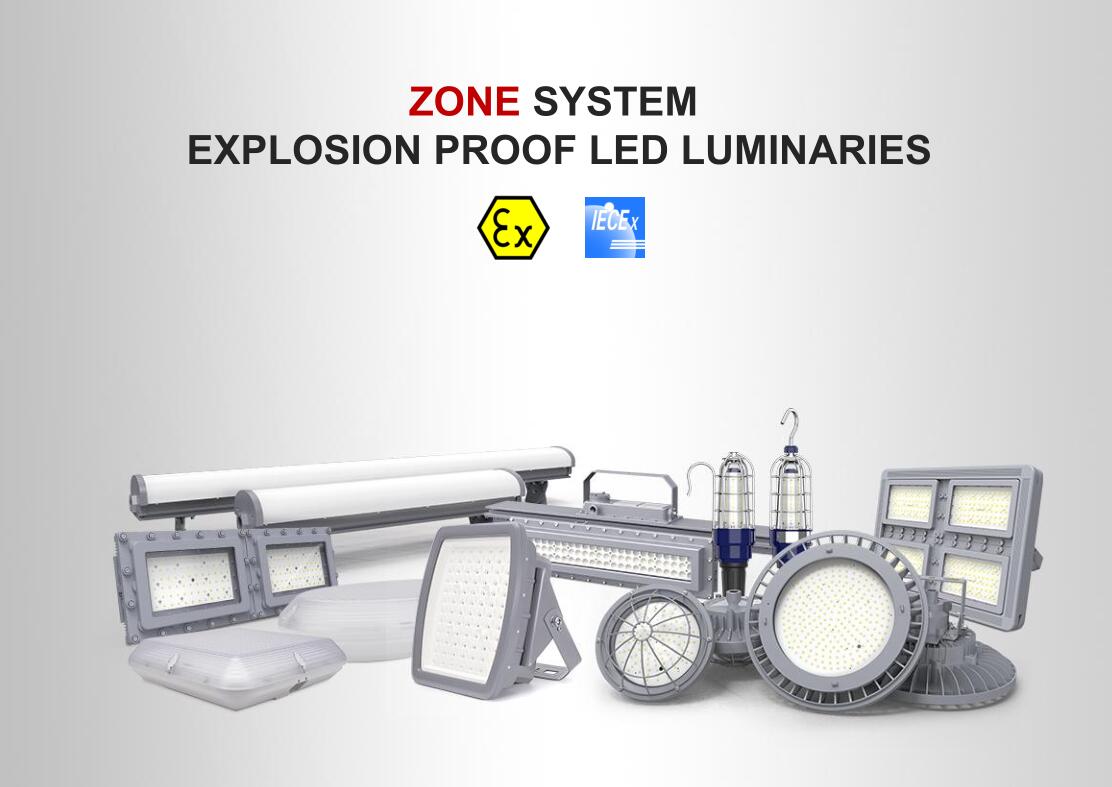

For Zone 1 Zone 2, Zone 21 Zone 22 hazardous area led lighting, 20W - 200W, 130lm/W,aluminum alloy + 8mm tempered glass, multi-installation for different projects, such as light tower, canopy light, marine grade.

Flameproof enclosure, Ex db op is IIC T6 Gb, Zone 1 & Zone 21 with explosive gas atmosphere, Zone 21 and Zone22 with explosive dust atmosphere, 10mm temered glass, 7J impact resistance,up to 26000lm.

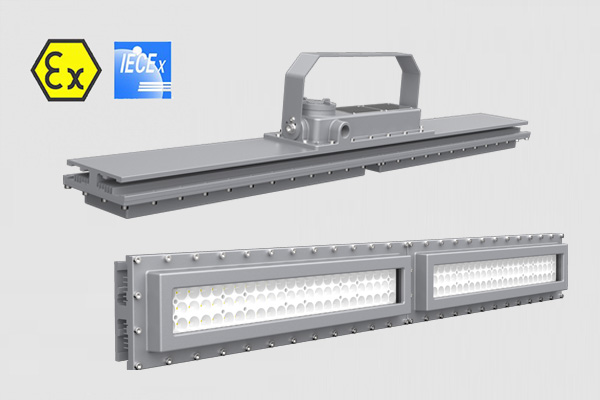

Flameproof enclosure, Ex db op is IIC T6 Gb, IP68 protection grade, tempered glass 10mm, withstand impacts up to 10J, 2 foot and 4 foot Length, 50Watt- 240Watt, 130lm/W light efficacy.

Zone 1 & Zone 21, 1ft, 2ft, 3ft, 4ft length can be selected, replace the traditional explosion-proof three-proof lamp, explosion-proof fluorescent tube, anti-corrosion, anti-glare, anti-drop, competitive price.

Flameproof LED hand lamp for Zone 1 & Zone 21 hazardous areas, 10mm tempered glass, pass the multi-angle drop test, 10W, 20W, 30W Power, can be connected to the cable, emergency power box.

The CES-EX-SF series explosion-proof ceiling lamp has a strong shell, with features such as impact resistance, vibration resistance, and corrosion resistance. It can be used in hazardous environments of Zone 1&21, Zone 2&22.

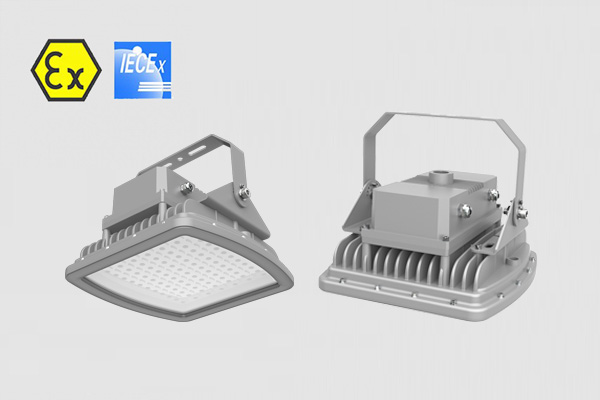

CES-EX-JX Series is your go-to solution for illuminating hazardous Zone 1 and Zone 21 areas. With ATEX approval, these Explosion-proof LED Flood Lights offer unbeatable safety standards.

Discover the pinnacle of safety and illumination with our CES-EX-GBX Series Explosion-proof LED High Bay Lights. Designed for hazardous Zone 1 and Zone 21 areas, these lights boast ATEX approval, ensuring the highest safety standards.

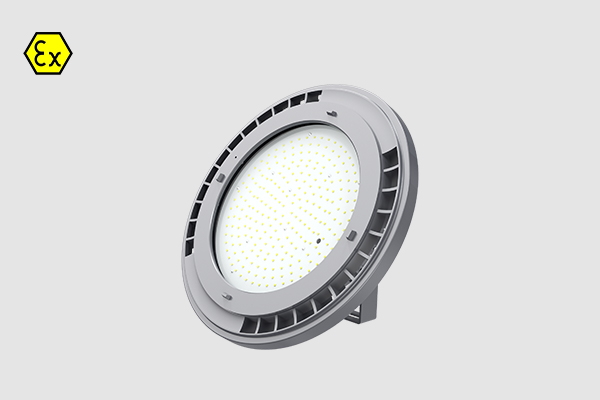

GB-02 explosion-proof lights are made of alloy aluminum and tempered glass, with shock resistance and anti-vibration performance. The luminaires have passed the ATEX IECEx standards test, from 30W to 80W for hazardous area lighting.

LN-02 explosion-proof lights obtained an IECEx ATEX certificate, it's safe for the Zone 1 and Zone 2 hazardous locations. The copper-free aluminum alloy body is powder-coated to increase durability and beautiful appearance, are able to withstand violent shaking and shock resistance.

an innovative line of LED hazardous area lighting products, specifically designed for use in potentially explosive atmospheres (Zone 1/21 & 2/22) within harsh industrial settings such as coal mines and oil & gas facilities.

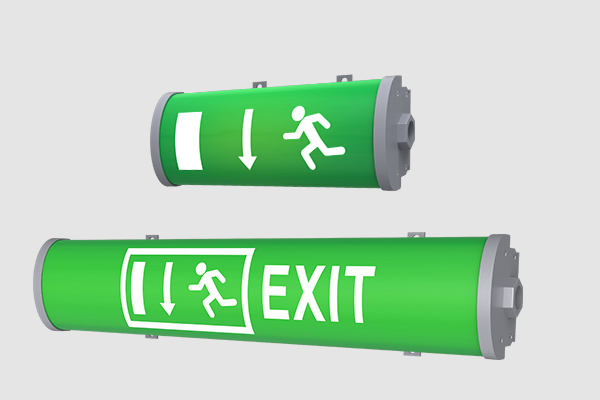

Explosion-proof safety exit lamps are for personnel evacuation, and fire operations to provide lighting fire emergency lamps! It usually uses an external power supply, when the power automatically switches to the battery power state!

Explosion Proof High Bay LED Light 60W - 100W

ATEX Explosion Proof LED Light - 70W 80W 100W

The CES-EX-D-GBX Series is a line of explosion-proof LED high bay lights designed for use in hazardous locations, specifically Zone 1 and Zone 2 areas. These lights are ATEX-approved, which indicates they meet the safety standards set forth by the European Union for equipment to be used in potentially explosive atmospheres.

Explosion-Proof Design: These LED high bay lights are designed to prevent the ignition of hazardous gases, vapors, or dust in the surrounding environment. This is crucial in industrial settings where explosive materials may be present.

Various Wattage Options: The series offers a range of wattage options, including 70W, 80W,100W, and 120W. This allows you to choose the appropriate level of illumination for your specific application.

ATEX Approved: ATEX (Atmosphères Explosibles) is a certification that ensures equipment is suitable for use in explosive atmospheres. This approval indicates that the lights have met the necessary safety standards for such environments.

Features

- -40°C to +40°C/50°C/60°C ambient temperature

- Wide optics for uniform illumination

- 5 years warranty

- Housing – Aluminum alloy (ADC12)

- Lens – tempered glass

- Dimension: 266.5*280mm

- Weight: 5.8KG

Parameters

- Power: 60W / 70W / 80W / 100W

- Input voltage: AC110-277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 130lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: High Efficiency Driver

Certificate & Standard

Certifications and compliances for hazardous location.

-

CNEX Certificate No. : CMExC23.1137

• Ex db IIC T6 Gb;

• Ex tb IIIC T80°C Db;

• IP66; -

ATEX Certificate No. : TUV CY 24 ATEX 0206973 X

• Ex ll 2G Ex db op is IC T6…T4 Gb

• Ex II 2D Ex op is tb IIIC T130 ℃Db

Mounting

Versatile mounting options:

- U-bracket mount

- Pole mount

- Pile mount

Explosion Proof High Bay LED Light 30W - 50W

ATEX Explosion Proof LED Light - 30W 40W 50W

The CES-EX-D-GBX Series is a line of explosion-proof LED high bay lights designed for use in hazardous locations, specifically Zone 1 and Zone 2 areas. These lights are ATEX-approved, which indicates they meet the safety standards set forth by the European Union for equipment to be used in potentially explosive atmospheres.

Explosion-Proof Design: These LED high bay lights are designed to prevent the ignition of hazardous gases, vapors, or dust in the surrounding environment. This is crucial in industrial settings where explosive materials may be present.

Various Wattage Options: The series offers a range of wattage options, including 30W, 40W, 50W, and 60W. This allows you to choose the appropriate level of illumination for your specific application.

ATEX Approved: ATEX (Atmosphères Explosibles) is a certification that ensures equipment is suitable for use in explosive atmospheres. This approval indicates that the lights have met the necessary safety standards for such environments.

Features

- Luminous flux: 3900lm / 5200lm / 6500lm

- -40°C to +40°C/50°C/60°C ambient temperature

- Wide optics for uniform illumination

- 5 years warranty

- Housing – Aluminum alloy (ADC12)

- Lens – tempered glass

- Dimension: 242*280mm

- Weight: 4.5KG

Parameters

- Power: 30W / 40W / 50W

- Input voltage: AC110-277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 130lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: High Efficiency Driver

Certificate & Standard

Certifications and compliances for hazardous location.

-

CNEX Certificate No. : CMExC23.1137

• Ex db IIC T6 Gb;

• Ex tb IIIC T80°C Db;

• IP66; -

ATEX Certificate No. : TUV CY 24 ATEX 0206973 X

• Ex ll 2G Ex db op is IC T6…T4 Gb

• Ex II 2D Ex op is tb IIIC T130 ℃Db

Mounting

Versatile mounting options:

- U-bracket

- Pole mount

- Pile mount

Explosion Proof Portable Light 60W - 200W (4-Wheels)

PORTABLE LED EXPLOSION-PROOF LIGHTS (4-wheels)

Model No. CES-J60/80/100/120/150/200

CESP portable explosion-proof floodlight has a 4-wheel structure design, which is convenient to move anywhere. It is designed to withstand the harsh environment of hazardous locations, such as refineries, chemical plants, and mining operations, and obtained IECEx/ATEX/UL844 explosion-proof certificates. The maximum power is 185W and more than 24000lm output. You can also choose a 90-minute or 180-minute emergency plan according to users' needs.

• Wastewater treatment, oil, and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor walls, and stanchion-mounted general area lighting, where flammable vapors and gases are present.

Features

- Light efficacy: 130lm/W

- -40°C to +55°C ambient operating temperature

- Housing – Aluminum alloy (ADC12 )

- Lens – tempered glass

- Beam angle: 90° / 120°

- Power Driver: High-Efficiency LED Driver

Parameters

- Power: 60W / 80W / 100W / 120W/ 150W / 185W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- Working Time: 3 hours for emergency

Ex-proof Standard

NEC and CEC standards for hazardous locations and environments

-

ATEX:

- EX II 2G Ex eb mb op is IIC T4 Gb

- EX II 2D Ex op is tb IIIC T95°C Db

- IP66

- Certify No.:IEP 19ATEX 0714

IECEx:

- Ex ec IIC T4 Gc

- IP66

- Certify No: IECEx UL 18.0046

- UL844:

Class 1 Division 2, Groups A, B, C and D

Mounting

Versatile mounting options:

- Portable bracket with wheels

Explosion Proof Lighting in Egypt

Explosion-proof lighting is a specialized type of lighting that is designed to prevent explosions in hazardous locations where flammable gases, vapors, and dust are present. In Egypt, explosion-proof lighting is necessary for various industries such as oil and gas, chemical manufacturing, mining, and more.

Here is a brief overview of the distribution of these industries in Egypt:

- Oil and Gas: The oil and gas industry in Egypt is concentrated in the Western Desert, Gulf of Suez, and Nile Delta regions. The Western Desert is the largest oil-producing region, while the Nile Delta region has significant natural gas reserves. The Gulf of Suez region is home to the country's largest oil refineries and petrochemical plants.

- Chemical Manufacturing: The chemical manufacturing industry in Egypt is located mainly in the Greater Cairo area, with a few facilities in Alexandria and other regions. The industrial city of Suez, located on the Red Sea, is also a hub for chemical manufacturing and petrochemicals.

- Mining: Egypt has a rich history of mining, and the industry is distributed across the country in different regions. The Eastern Desert and the Sinai Peninsula are rich in mineral resources, including gold, copper, and iron ore. The Western Desert is also home to several mining operations, including phosphate mines.

There are several companies in Egypt that provide explosion-proof lighting solutions. Some of these companies include:

- Explosion-Proof Egypt: This company specializes in providing explosion-proof electrical equipment and lighting solutions for hazardous areas in Egypt.

- Petrotech: Petrotech is a leading provider of explosion-proof lighting solutions for the oil and gas industry in Egypt.

- STAHL Egypt: R. STAHL is a global supplier of explosion-proof lighting and electrical products for hazardous areas. They have a presence in Egypt and provide high-quality lighting solutions for various industries.

- Elhamd: Elhamd is an Egyptian company that provides explosion-proof lighting solutions for hazardous areas in the country.

It is essential to choose a reputable and experienced company to provide explosion-proof lighting solutions to ensure safety and compliance with regulations.

What's the type and certificate requirement of explosion-proof lighting in Egypt?

In Egypt, explosion-proof lighting must comply with international standards and regulations, including the National Fire Protection Association (NFPA) and the International Electrotechnical Commission (IEC). The following are the types and certificate requirements for explosion-proof lighting in Egypt:

Types of Explosion-Proof Lighting: There are main two types of explosion-proof lighting in Egypt, which are Ex d and Ex e. Ex d lighting is designed for use in areas where flammable gases, vapors, and dust are present and is suitable for Zone 1 and Zone 2 hazardous locations. Ex e lighting is designed for use in areas where flammable gases and vapors are present and is suitable for Zone 1, Zone 2, and Zone 21 hazardous locations.

Certification Requirements: In Egypt, explosion-proof lighting must be certified by a recognized certification body such as the International Electrotechnical Commission's (IEC) Certification Body (IECEE). The certification ensures that the lighting meets the required safety and performance standards for use in hazardous locations. The certification requirements include:

- A certificate of conformity (CoC) issued by a recognized certification body

- A mark indicating the level of protection and hazardous location classification

- Documentation proving compliance with international standards and regulations

- Quality control and testing procedures to ensure the lighting meets the required safety and performance standards.

- It is essential to choose explosion-proof lighting that meets the required international standards and regulations and is certified by a recognized certification body to ensure safety and compliance with regulations in Egypt.

Explosion Proof Lighting South Africa

The explosion-proof lighting market in South Africa is expected to experience significant growth in the coming years. This is due to the country's expanding industrial sector, which includes oil and gas, mining, and chemical industries. The need for lighting fixtures that can operate safely in potentially explosive environments is driving the demand for explosion-proof lighting.

The main application fields of explosion-proof lighting in South Africa include

Oil and Gas Industry: The oil and gas industry is one of the primary users of explosion-proof lighting in South Africa. The lighting fixtures used in this industry must be able to withstand harsh environments and the potential for explosive gases or liquids.

Mining Industry: The mining industry is another major user of explosion-proof lighting. The lighting fixtures used in mining must be able to withstand dust, moisture, and potential explosive gases.

Chemical Industry: The chemical industry also requires explosion-proof lighting fixtures to ensure safety in potentially explosive environments.

Food and Beverage Industry: The food and beverage industry may also use explosion-proof lighting in areas where there is a potential for flammable gases or liquids.

The type of explosion-proof light in South Africa

The type of explosion-proof lamps needed in the South African market depends on the specific requirements of the industry or application. However, some common types of explosion-proof lamps used in South Africa include:

LED explosion-proof lamps: These lamps are highly energy-efficient, have a longer lifespan, and are less prone to failure compared to traditional lighting fixtures. They also produce less heat, which is beneficial in hazardous environments.

Fluorescent explosion-proof lamps: These lamps are also commonly used in South Africa due to their energy efficiency and long lifespan. They are available in different sizes and shapes, making them suitable for various applications.

High-intensity discharge (HID) explosion-proof lamps: These lamps are known for their high brightness and are often used in outdoor applications. They are available in different types, such as mercury vapor, metal halide, and high-pressure sodium.

Incandescent explosion-proof lamps: These lamps are the traditional type of lighting fixture, but they are less commonly used due to their low energy efficiency and short lifespan.

Overall, the South African market requires durable, reliable, and energy-efficient explosion-proof lights that are certified to ensure their safety in hazardous environments. The type of lamp selected depends on the specific requirements of the industry or application. However, with the requirements of the global market, in South Africa, LED explosion-proof lamps will gradually replace traditional explosion-proof lamps.

Certificates that are needed for explosion-proof lighting in South Africa include

SABS certification: This is the South African Bureau of Standards certification, which is required for electrical and electronic products sold in South Africa.

IECEx certification: This international certification system for equipment used in explosive atmospheres is recognized in South Africa.

ATEX certification: This certification is required for equipment used in potentially explosive atmospheres in the European Union, and is also recognized in South Africa.

In conclusion, the explosion-proof lighting market in South Africa is driven by the growing industrial sector, and the main application fields for explosion-proof lighting include oil and gas, mining, chemical, and food and beverage industries. SABS, IECEx, and ATEX certifications are required for explosion-proof lighting fixtures in South Africa.

LED Lighting for the LNG, LPG and CNG plant

What is the difference between LNG LPG and CNG?

LNG, LPG, and CNG are all forms of natural gas, but they differ in their physical state and the way they are stored and transported.

LNG (Liquefied Natural Gas) is natural gas that has been cooled to a very low temperature (-162°C) to convert it into a liquid state. LNG takes up less space than natural gas in its gaseous state, making it more practical for storage and transportation over long distances, such as by ship. It is mainly used in large-scale applications, such as power generation, industrial processes, and as fuel for marine vessels.

LPG (Liquefied Petroleum Gas), on the other hand, is a mixture of propane and butane gases that are stored in a pressurized state as liquids. LPG is often used as a fuel for heating, cooking, and in some vehicles. It is commonly found in small portable cylinders, as well as larger tanks for use in industrial and commercial settings.

CNG (Compressed Natural Gas) is natural gas that has been compressed to a high pressure (typically around 200-250 bar) to reduce its volume and make it more practical for storage and transportation. CNG is mainly used as fuel for vehicles, and it is stored in high-pressure cylinders or tanks that can be refueled at CNG refueling stations.

In summary, LNG is natural gas in a liquid state, mainly used for large-scale applications such as power generation and industrial processes. LPG is a mixture of propane and butane gases stored in a pressurized state as liquids, often used for heating, cooking, and in some vehicles. CNG is natural gas compressed to high pressure and mainly used as fuel for vehicles.

Explosion Proof Lights for the LNG, LPG, and CNG plant

Explosion-proof lights are essential for industries where flammable gases or liquids are present, such as LNG (liquefied natural gas), LPG (liquefied petroleum gas), and CNG (compressed natural gas) plants. These plants require specific lighting solutions that can withstand harsh conditions and prevent potential explosions due to electrical equipment, including lighting fixtures.

The use of explosion-proof lights in these plants depends on the hazardous area classification, which is typically classified into Zone 1 and Zone 2. Zone 1 is an area where flammable gases or vapors may be present in normal operating conditions, while Zone 2 is an area where these substances are less likely to be present or may only be present for a short period.

For hazardous locations, explosion-proof lighting fixtures must meet specific standards and certifications to ensure they are suitable for use in these environments. These certifications are typically provided by organizations such as the International Electrotechnical Commission (IEC) or the Underwriters Laboratories (UL).

In the United States, explosion-proof lighting fixtures must be certified by the Occupational Safety and Health Administration (OSHA) and meet specific National Electrical Code (NEC) requirements. These requirements vary based on the specific application and hazardous area classification.

In summary, the use of explosion-proof lights in LNG, LPG, and CNG plants is critical for ensuring the safety of personnel and preventing potential explosions. Hazardous area classifications such as Zone 1 and Zone 2, as well as specific certifications and standards, must be considered when selecting the appropriate lighting fixtures for these environments.

At CESP, we understand that lighting is a critical component in ensuring the safety and efficiency of LNG plants. That's why we have developed a range of lighting solutions specifically designed for the unique needs of the industry.

Our explosion-proof lights are built to withstand the harsh and hazardous environments of LNG plants, ensuring that your workers and assets are protected at all times. We use the latest LED technology to provide bright, energy-efficient lighting that can reduce your operational costs.

We have a proven track record of providing lighting solutions to some of the biggest names in the industry, including Sinopec. Our team of experts has the knowledge and experience to design and implement lighting solutions that meet your specific requirements, no matter how complex they may be.

So if you are Looking for reliable and high-quality lighting solutions for your LNG plants. Look no further than CESP and let us help you light up your LNG plant with our high-quality and reliable lighting solutions.

Explosion Proof Lighting Australia

The Australian explosion-proof light market is growing due to the increasing demand for explosion-proof lighting solutions in hazardous environments such as oil and gas refineries, chemical plants, mining sites, and offshore oil rigs. Explosion-proof lamps are designed to prevent the ignition of flammable gases, vapors, and dust particles, thereby ensuring safety in hazardous locations.

Market Analysis:

The Australian explosion-proof light market is expected to witness significant growth in the coming years due to the increasing demand for explosion-proof lighting solutions in hazardous environments. According to Markets, the global explosion-proof lighting market size is projected to grow from USD 340 million in 2020 to USD 471 million by 2025, at a CAGR of 6.7%. This growth is attributed to the increasing demand for explosion-proof lighting solutions in various industries such as oil and gas, chemical, pharmaceutical, and mining.

Explosion-Proof Requirement Standards and Certification:

In Australia, explosion-proof lighting products must comply with the relevant standards and certification requirements to ensure their suitability for use in hazardous locations. The Australian Standard AS/NZS 60079.0:2012 sets out the general requirements for explosion-proof equipment, while AS/NZS 60079.1:2011 specifies the requirements for explosion-proof lighting. The products must also be certified by the relevant certification bodies such as the International Electrotechnical Commission (IEC) or the Australian Government Department of Industry, Science, Energy, and Resources.

IECEx is an international certification system for explosion-proof equipment, including lighting fixtures, that are intended for use in hazardous locations such as Zone 1 and Zone 21 in Australia. IECEx certification is based on international standards and provides a single certification that is recognized by many countries, including Australia.

Several series of CESP explosion-proof lights have obtained IECEx certificates, which can be used in gas explosion environments (Zone 1 & Zone 2) and sub-explosion environments (Zone 21 & Zone 22), which meet the requirements of the Australian explosion-proof certificate.

Explosion-proof lights are designed to operate in hazardous environments with a risk of explosions due to the presence of flammable gases, vapors, and dust particles. These environments include mines, oil and gas refineries, chemical plants, pharmaceutical factories, mining sites, and offshore oil rigs. The lamps are built to withstand extreme temperatures, shock, and vibration and are designed to prevent the ignition of flammable gases, vapors, and dust particles. Depending on the specific application and requirements, explosion-proof lamps are available in various types, including fluorescent, LED, incandescent, and HID lamps.

Explosion-proof lights are more commonly used in mines in Western Australia because of the hazardous nature of the mining environment. Mines are considered hazardous locations due to the presence of flammable gases, vapors, and dust particles that can ignite and cause explosions.

Mine Industry in Western Australia Market Analysis:

The mining industry in Western Australia is a mature and well-established industry, with a diverse range of minerals being produced, including iron ore, gold, nickel, bauxite, alumina, and mineral sands. According to the Western Australian Department of Mines, Industry Regulation, and Safety (DMIRS), the value of the state's mineral and petroleum industry was AUD 123.2 billion in 2020-21. The industry has experienced significant growth over the last decade, with mining production increasing by 65% between 2009-10 and 2019-20.

In addition, mining operations in Western Australia often operate in remote areas with limited access to infrastructure and emergency services. The use of explosion-proof lights ensures that lighting is available in hazardous environments without the risk of explosions, thereby improving safety and reducing the risk of accidents.

Furthermore, mining operations in Western Australia are subject to strict safety regulations and standards to ensure that mining activities are conducted in a safe and sustainable manner. The use of explosion-proof lights is required by law in hazardous locations to comply with these safety regulations and standards.

The use of explosion-proof lights in mines in Western Australia is essential to ensure the safety of workers and comply with safety regulations and standards. The hazardous nature of the mining environment makes the use of explosion-proof lights crucial in preventing explosions caused by electrical equipment and improving safety in mining operations.

In conclusion, the Australian explosion-proof light market is growing due to the increasing demand for explosion-proof lighting solutions in hazardous environments. The products must comply with the relevant standards and certification requirements to ensure their suitability for use in hazardous locations. The lamps are designed to operate in extreme environments and are available in various types, depending on the specific application and requirements.

Explosion-Proof LED Lamps for Hazardous Areas - Zone System Classification

Explosion-proof LED lamps are designed to be used in hazardous areas, where the presence of flammable gases, vapors, or dust can cause explosions or fires. These lamps are specially designed to prevent the ignition of such hazardous materials and are classified into different zones based on the level of risk.

The Zone System is a method of classification for hazardous areas, which is widely used in the industry. The system is based on three zones, namely Zone 0, Zone 1, and Zone 2, each representing a different level of risk.

- Zone 0 is the highest risk zone, where explosive gases or vapors are continuously present or present for long periods of time. In this zone, only explosion-proof equipment with the highest level of protection is allowed to be used.

- Zone 1 is an area where explosive gases or vapors are likely to be present under normal operating conditions. In this zone, explosion-proof equipment with a lower level of protection is allowed to be used.

- Zone 2 is an area where explosive gases or vapors are unlikely to be present under normal operating conditions. However, if they do occur, it will be for a short period of time. In this zone, explosion-proof equipment with the lowest level of protection is allowed to be used.

Explosion-proof LED lamps of the zone system are designed to meet the requirements of these hazardous areas. They are constructed with materials that prevent sparks or flames from igniting explosive gases or vapors. Additionally, they are designed to be shock and vibration-resistant to prevent accidental damage.

In summary, explosion-proof LED lamps of the zone system are designed to provide safe lighting solutions for hazardous areas. They are classified into different zones based on the level of risk, and each zone requires different levels of protection. These lamps are essential for ensuring the safety of workers and preventing explosions or fires in these hazardous areas.

In addition to the three zones (Zone 0, Zone 1, and Zone 2) of the Zone System for hazardous areas, there are also two additional zones, Zone 21 and Zone 22, which are related to the presence of combustible dust.

Zone 21 is an area where combustible dust is likely to be present in the air during normal operating conditions. In this zone, explosion-proof equipment with a higher level of protection is required.

Zone 22 is an area where combustible dust is not likely to be present in the air during normal operating conditions. However, if it does occur, it will be for a short period of time. In this zone, explosion-proof equipment with a lower level of protection is required.

Explosion-proof LED lamps of the zone system are designed to meet the requirements of all five zones. They are designed with materials that prevent sparks or flames from igniting hazardous gases, vapors, or combustible dust. These lamps are constructed with robust housing that is resistant to impact, vibration, and corrosion. They are also designed with specialized heat dissipation systems that prevent the buildup of heat, which can be a source of ignition.

In summary, explosion-proof LED lamps of the zone system are classified into five zones (Zone 0, Zone 1, Zone 2, Zone 21, and Zone 22) based on the level of risk posed by the presence of hazardous materials. These lamps are essential for providing safe lighting solutions for hazardous areas and are designed to meet the strict safety requirements of each zone.

What is the difference between the Zone system for IECEx and ATEX certificate?

The Zone System is a method of classification for hazardous areas that are used in both the IECEx and ATEX certification schemes. However, there are some differences between the two systems.

The IECEx certification scheme is an international standard for equipment intended for use in explosive atmospheres. The Zone System used in the IECEx scheme is based on three zones, namely Zone 0, Zone 1, and Zone 2, which are the same as the zones used in the ATEX scheme.

However, the IECEx scheme has some additional requirements, such as the use of "Ex ia" (intrinsic safety) protection method for Zone 0 equipment, which is not required by the ATEX scheme. Additionally, the IECEx scheme requires that equipment be tested and certified by a recognized third-party certification body, while the ATEX scheme allows manufacturers to self-certify their equipment.

Another difference between the two schemes is that the IECEx scheme is accepted in a larger number of countries around the world, while the ATEX scheme is primarily used in Europe.

In summary, both the IECEx and ATEX certification schemes use the Zone System for hazardous area classification. However, the IECEx scheme has some additional requirements and is more widely recognized internationally, while the ATEX scheme is primarily used in Europe.

Here are some potential selling points for CESP Zone system explosion-proof lamps

- Safety: Our Zone system explosion-proof lamps are designed to provide a safe lighting solution for hazardous areas. They are constructed with materials that prevent sparks or flames from igniting hazardous gases, vapors, or combustible dust.

- Versatility: Our explosion-proof lamps are designed to meet the requirements of all five zones (Zone 0, Zone 1, Zone 2, Zone 21, and Zone 22), making them a versatile solution for a wide range of hazardous environments.

- Efficiency: Our explosion-proof LED lamps are energy-efficient and long-lasting, reducing maintenance and replacement costs. They also provide bright, consistent lighting in even the harshest conditions.

- Durability: Our explosion-proof lamps are built with rugged, corrosion-resistant housing that can withstand impact, vibration, and harsh weather conditions. This ensures reliable performance and a long lifespan.

- Compliance: Our lamps are designed and tested to comply with international standards for explosion-proof equipment, including ATEX, IECEx, and UL. This ensures that they meet the strict safety requirements of hazardous environments.

- Mount optional: We offer a range of mount options, to ensure that our lamps meet the specific needs of each customer and application.

- Expertise: Our team of experts has extensive experience in designing and manufacturing explosion-proof lighting solutions. We work closely with our customers to provide tailored solutions that meet their unique needs and ensure optimal safety and performance.

Click: https://cespledex.com/products/iecex-atex-certified-luminaires to find a variety of zone 1 Zone 21 explosion-proof lights

Explosion Proof LED Lamps of The Division System

Explosion-proof LED lamps that are designed for use in division systems must meet stringent safety requirements to prevent the ignition of flammable gases, vapors, or dust. There are five classes of division explosion-proof systems, each with its own set of conditions, and LED lamps must meet the requirements of the specific class in which they will be used.

Class 1 Division 1 (C1D1): This is the most hazardous location, where ignitable concentrations of flammable gases, vapors, or liquids are present continuously or frequently. LED lamps designed for use in Class 1 Division 1 location must be hermetically sealed and designed to withstand and contain any potential explosions. They must also be made of non-sparking materials and meet rigorous testing requirements to ensure they can operate safely under normal and fault conditions.

Class 2 Division 1 (C1D2): This is a location where combustible dust is present in the air in sufficient quantities to create a hazardous condition. LED lamps designed for use in Class 2 Division 1 locations must be designed and tested to prevent the ignition of dust particles and must be made of non-sparking materials to prevent sparking.

Class 1 Division 2 (C2D1): This is a location where ignitable concentrations of flammable gases, vapors, or liquids are present, but only under abnormal conditions or during equipment failure. LED lamps designed for use in Class 1 Division 2 locations must be designed to prevent the ignition of flammable materials under normal operating conditions and must be made of non-sparking materials to prevent sparking.

Class 2 Division 2 (C2D2): This is a location where combustible dust is present, but only under abnormal conditions or during equipment failure. LED lamps designed for use in Class 2 Division 2 locations must be designed and tested to prevent the ignition of dust particles and make non-sparking materials to prevent sparking.

Class III: This class applies to locations where ignitable fibers or flyings are present, such as in textile mills or woodworking shops. LED lamps designed for use in Class III locations must be designed and tested to prevent the ignition of these materials and must be made of non-sparking materials to prevent sparking.

Choose a Better Division System Ex-proof Lights from CESP

In addition to meeting the requirements of the specific class in which they will be used, LED lamps for division explosion-proof systems must also comply with other standards and certifications, such as UL Listing, CSA Certification, ATEX Certification, FM Approval, or IECEx Certification, to ensure their safety and effectiveness.

When it comes to hazardous work environments, proper lighting is crucial for ensuring safety and productivity. That's why the National Electric Code (NEC) has established guidelines for the use of electrical equipment in areas where explosive gases, dust, or other combustible materials may be present. These guidelines classify hazardous areas into four different classes, and each class has two divisions, which are used to determine the level of protection required for electrical equipment.

Class 1 Div 1 Lighting:

Class 1 Div 1 LED lights are designed for use in areas where explosive gases or vapors are present continuously or intermittently under normal operating conditions. These areas are typically found in petroleum refineries, chemical plants, and other similar facilities. Class 1 Div 1 LED lights are required to be explosion-proof, which means they must be able to withstand an explosion without igniting the surrounding gases or vapors. They must also be able to operate at temperatures that are high enough to prevent the formation of explosive gases or vapors.

Class 1 Div 2 Lighting:

Class 1 Div 2 LED lights are designed for use in locations where flammable gases or vapors may be present under abnormal conditions. These lights are suitable for use in Class I, Division 2 hazardous locations as defined in NEC Article 500. Class 1 Div 2 LED lights are designed to be spark-free and feature explosion-proof enclosures to prevent the ignition of hazardous substances in the surrounding environment. They are commonly used in oil refineries, chemical plants, and other industrial facilities where flammable gases or vapors are present.

Class 2 Div 1 Lighting:

Class 2 Div 1 LED lights are designed for use in areas where combustible dust is present continuously or intermittently under normal operating conditions. These lights are suitable for use in Class II, Division 1 hazardous location as defined in NEC Article 502. Class 2 Div 1 LED lights are designed to prevent the ignition of combustible dust in the surrounding environment by using dust-tight enclosures and non-sparking materials. They are commonly used in grain elevators, flour mills, and other facilities where combustible dust is present.

Class 2 Div 2 Lighting:

Class 2 Div 2 LED lights are designed for use in locations where combustible dust may be present under normal operating conditions such as during maintenance or cleaning. These lights are suitable for use in Class II, Division 2 hazardous locations as defined in NEC Article 502. Class 2 Div 2 LED lights are designed to prevent the ignition of combustible dust in the surrounding environment by using dust-resistant enclosures and other protective measures. They are commonly used in food processing facilities, pharmaceutical plants, and other facilities where combustible dust is present.

In conclusion, selecting the appropriate LED light for hazardous locations requires careful consideration of the specific conditions present in each location. By understanding the NEC guidelines for Class 1 Div 1, Class 1 Div 2, Class 2 Div 1, and Class 2 Div 2 areas, you can make informed decisions to ensure the safety of your workers and equipment.

At our company, we offer UL844 class 1 division 1 and class 1 division 2 LED lights that provide safe and efficient illumination in hazardous locations. Our class 1 division 1 LED lights are explosion-proof and ruggedly constructed, making them suitable for areas with flammable gases or vapors. Our class 1 division 2 LED lights are cost-effective and designed for areas where flammable gases or vapors are not typically present but may be accidentally present. Both LED lights are highly energy-efficient and have a long lifespan, reducing maintenance needs and electricity bills.

Choosing our UL844 class 1 division 1 and class 1 division 2 LED lights ensures a reliable and safe lighting solution for hazardous locations. Contact us today to learn more about our products and how they can meet your lighting needs.

Visit: https://cespledex.com/products/ul-hazloc-certified-led-luminaires

2023 North American Explosion Proof Lighting Market Analysis and Certification Guidelines

Analysis of the North American Explosion-Proof Lights Market Situation

The North American explosion-proof light market is driven by the increasing demand for explosion-proof lighting systems across various end-use industries, including oil and gas, chemicals, mining, and pharmaceuticals. These industries have strict safety regulations, which have led to a growing need for explosion-proof lighting systems to prevent accidents and ensure worker safety.

Market Size:

The North American Explosion Proof Lighting Market has been growing steadily in recent years due to increasing safety regulations and the need for reliable and durable lighting solutions in hazardous environments. According to a report by MarketsandMarkets, the North American Explosion Proof Lighting Market was valued at USD 307.4 million in 2020 and is projected to reach USD 376.2 million by 2025, with a CAGR of 4.1% during the forecast period (2020-2025).

The United States is the largest market for explosion-proof light in North America, due to its large oil and gas industry and the presence of major players in the region. The Canadian market is also growing, driven by increasing investments in the mining and oil and gas industries.

Key Drivers:

Several factors are driving the growth of the North American Explosion Proof Lighting Market:

1. Stringent Safety Regulations: The increasing focus on workplace safety and the implementation of stringent regulations by regulatory bodies such as Occupational Safety and Health Administration (OSHA) and National Fire Protection Association (NFPA) are driving the demand for explosion-proof lighting solutions in North America.

2. Growth in Hazardous Industries: The growth of industries such as oil and gas, petrochemicals, chemicals, and mining in North America is creating a demand for explosion-proof lighting solutions. These industries often operate in hazardous environments where the risk of explosions is high, and reliable lighting solutions are required for safe operations.

3. Technological Advancements: Advancements in lighting technologies, such as LED (Light Emitting Diode) and induction lighting, are driving the adoption of explosion-proof lighting solutions. LED-based explosion-proof lighting fixtures are energy-efficient, long-lasting, and provide bright illumination, making them ideal for hazardous environments.

4. Retrofitting of Existing Infrastructure: The retrofitting of existing lighting infrastructure in hazardous environments with explosion-proof lighting solutions is also driving the demand for these products in North America. Many industrial facilities are upgrading their lighting systems to comply with safety regulations and improve operational efficiency, which is creating opportunities for explosion-proof lighting manufacturers.

Challenges:

However, the market also faces some challenges, including the high cost of explosion-proof lighting systems, which may limit their adoption in some industries, as well as the increasing competition from other lighting solutions such as LED bulbs and fixtures., including:

1. High Cost: Explosion-proof lighting fixtures are typically more expensive than regular lighting fixtures due to their specialized design and construction to withstand hazardous environments. The high cost of these fixtures may pose a challenge to small and medium-sized enterprises (SMEs) with limited budgets.

2. Rapid Technological Changes: The lighting industry is constantly evolving with new technologies and innovations. Keeping up with these rapid changes and incorporating the latest technologies into explosion-proof lighting fixtures may be a challenge for manufacturers, especially smaller players with limited resources.

3. Competition from Substitutes: There may be competition from alternative lighting solutions such as portable explosion-proof lighting equipment, temporary lighting solutions, or use of natural light in certain applications, which may impact the demand for fixed explosion-proof lighting fixtures.

Key players in the North American explosion-proof luminaires market include Dialight, Eaton Corporation, Hubbell Incorporated, Acuity Brands Lighting, and Emerson Electric Co. These companies are focusing on developing innovative and energy-efficient lighting solutions to meet the growing demand for explosion-proof light in the region.

The North American explosion-proof light market is expected to continue growing in the coming years, driven by increasing safety regulations, technological advancements, and the growing demand for energy-efficient lighting solutions.

Standards and Requirements for explosion-proof Lamps in North America

Explosion-proof lamps are lighting fixtures designed to prevent the ignition of hazardous materials in potentially explosive environments. In North America, there are several standards and requirements that explosion-proof lamps must meet to ensure their safety and effectiveness.

In the United States, the Occupational Safety and Health Administration (OSHA) sets standards for explosion-proof lighting in hazardous locations, which are defined as areas where the potential for fire or explosion exists due to the presence of flammable gases, vapors, liquids, or combustible dust. OSHA requires that all lighting fixtures in hazardous locations be explosion-proof, which is designed to contain any potential explosions within the fixture, preventing them from spreading into the surrounding environment.

In addition to OSHA standards, explosion-proof lighting fixtures in the United States must also comply with the National Electrical Code (NEC), which sets safety standards for electrical installations. The NEC outlines requirements for the design, construction, and installation of explosion-proof fixtures, as well as the types of hazardous locations where they can be used.

In Canada, explosion-proof lighting fixtures must comply with the Canadian Electrical Code (CEC), which is similar to the NEC in the United States. The CEC sets safety standards for electrical installations and equipment in hazardous locations, including requirements for the design, construction, and installation of explosion-proof fixtures.

Overall, explosion-proof lighting fixtures in North America must meet strict safety standards to ensure their effectiveness and prevent potential accidents in hazardous environments.

What certificates are required for explosion-proof lamps in North America

In North America, explosion-proof lamps must comply with certain certification requirements to ensure their safety and suitability for use in hazardous environments. The following are some of the most common certification requirements for explosion-proof lamps in North America:

- UL Listing: UL (Underwriters Laboratories) is a leading certification organization that tests and certifies products for safety and performance. Explosion-proof lamps must be UL listed to ensure they meet safety standards and comply with regulations in the United States.

- CSA Certification: CSA (Canadian Standards Association) is a certification organization that tests and certifies products for safety and performance in Canada. Explosion-proof lamps must be CSA certified to ensure they meet safety standards and comply with regulations in Canada.

- ATEX Certification: ATEX is a certification requirement for explosion-proof lamps used in the European Union. However, it may also be required in North America for lamps that are used in global applications. ATEX certification ensures that the lamps meet safety standards and comply with regulations in the European Union.

- FM Approval: FM (Factory Mutual) is a certification organization that tests and certifies products for safety and performance. FM approval is often required for explosion-proof lamps used in the United States to ensure they meet safety standards and comply with regulations.

- IECEx Certification: IECEx is a certification requirement for explosion-proof lamps used in international applications. IECEx certification ensures that the lamps meet safety standards and comply with regulations in countries that recognize the IECEx scheme.

The certificates are not the same, and there will be some differences in the standards. Normal, most North American customers accept division explosion-proof system

The difference between the division explosion-proof system and the zone explosion-proof system

Division explosion-proof systems and zone explosion-proof systems are both types of electrical systems designed to prevent explosions in hazardous environments. However, they differ in the way they classify and regulate hazardous locations.

In North America, the division explosion-proof system is commonly used and is based on the National Electrical Code (NEC). The division system divides hazardous locations into two groups: Division 1 and Division 2. Division 1 locations are those where explosive gases, vapors, or dusts are present continuously or intermittently, while Division 2 locations are those where these materials are handled, processed, or stored but are not normally present in the air in explosive concentrations.

In a division explosion-proof system, electrical equipment installed in Division 1 locations must be designed and tested to prevent the ignition of explosive materials under normal operating conditions and fault conditions, such as short circuits and ground faults. Equipment installed in Division 2 locations is designed to prevent the ignition of explosive materials under normal operating conditions only.

In contrast, the zone explosion-proof system is used in Europe, Asia, and other parts of the world and is based on the International Electrotechnical Commission (IEC) standards. The zone system divides hazardous locations into three zones: Zone 0, Zone 1, and Zone 2. Zone 0 locations are those where explosive gases, vapors, or dust are present continuously or for long periods, while Zone 1 locations are those where these materials are likely to be present in normal operating conditions, and Zone 2 locations are those where these materials are unlikely to be present but may occur for short periods of time.

In a zone explosion-proof system, electrical equipment installed in Zone 0 locations must be designed and tested to prevent the ignition of explosive materials under normal operating conditions and fault conditions. Equipment installed in Zone 1 locations is designed to prevent ignition of explosive materials under normal operating conditions, and in Zone 2 locations, the equipment is designed to prevent the formation of sparks or arcs that could ignite explosive materials.

Overall, both division and zone explosion-proof systems are designed to prevent explosions in hazardous environments, but they differ in the way they classify hazardous locations and regulate the design and testing of electrical equipment.