Hot Strip Mill lighting solution

The main task of the steelmaking plant is to desulfurize, dephosphorize, decarburize, and deoxidize the molten iron, and then cast the molten steel into steel billets. The hot rolling plant is an important step in the production of steel bars. It will make the steel embryos through hot rolling or cold rolling again after heating and rolling for several times, and then cut the edge and correct them to finally become steel plates.

Many hot-rolling workshops use relatively old-fashioned metal halide lamps. The lamps have low light efficiency, high power consumption, high failure rate, and large after-sales maintenance. They cannot guarantee the lighting needs of on-site production. In order to solve the lighting problems, our company is based on the actual situation. Summarize and solve the lighting problem of the hot rolling plant from the fundamental problem.

The recommended lighting level in each area of the steel rolling workshop

|

no. |

workshop and workplace |

average illumination(lux) |

|

|

1 |

soaking furnace |

furnace top platform and meter room platform |

75 |

|

slag conveying corridor, platforms on all floors under the furnace, steel ingot car and motorcycle tunnel |

30 |

||

|

coke powder corridor, coke powder room |

30 |

||

|

rectifier room |

100 |

||

|

2 |

heating furnace |

beside heating furnaces such as thin plate, cold drawn, steel pipe workshops, etc., transport hot steel areas |

75 |

|

push the steel machine |

50 |

||

|

platforms on each floor of the basement of the heating furnace |

30 |

||

|

3 |

rolling mill area |

general ground |

75 |

|

rolling mill, hot saw, shearing machine place |

150 |

||

|

depress the screw indicator and hole pattern |

300 |

||

|

on the roller table of the rolling line, on the hot steel conveyor |

150 |

||

|

cooling bed |

75 |

||

|

4 |

main electrical room |

electrical room |

200 |

|

air-duct |

30 |

||

|

main control room |

500 |

||

|

5 |

operating room |

300 |

|

|

6 |

steel billet and finished product warehouse |

on the ground |

75 |

|

billet cutting location |

100 |

||

|

grinding machine, billet dressing station and slab pre-selection location |

300 |

||

|

printing, inspection, precision classification and acceptance |

500 |

||

|

finished product packaging location |

50 |

||

|

7 |

oil depot and general transmission basement |

50 |

|

|

8 |

correction machine |

50 |

|

|

9 |

spot welding location |

50 |

|

|

10 |

welding location |

100 |

|

|

11 |

heat treatment |

annealing |

50 |

|

pickling room |

100 |

||

- Slab library

|

Position Title |

Slab library |

|

|

The function and role of the post |

Numbering slabs, and stacking different slabs in different areas |

|

|

On-site characteristics |

Characteristics of building structure |

The plant is relatively spacious |

|

Features of the equipment |

Main equipment driving |

|

|

Characteristics of the environment |

Indoor environment, very high temperature, vibration |

|

|

Lamp requirements |

① The lamp is well sealed and has anti-vibration design. ② Lighting accessories (sealing ring etc. can withstand high temperature). ③ The electrical appliances have high temperature resistance and are easy to use inductive ballasts. ④ It is recommended to use split installation, place the electrical part on the side of the visitor channel, and the principle of hot steam dense area; |

|

|

Recommended lamps |

The CEX-EX-J explosion-proof LED flood light adopts a sealed structure with high waterproof and anti-corrosion performance. It meets UL1598A marine-level certification. The excellent heat dissipation structure design allows the efficiency and service life of the tube to withstand higher mechanical strength and temperature changes. The power cavity and the light source cavity are separated separately, and the explosion-proof performance is reliable. It is a cost-effective hazardous area floodlight with ATEX\IECEX\UL certification. |

|

- Heating furnace

|

Position Title |

Heating furnace |

|

|

The function and role of the post |

Heat the slab to about 1200 degrees and send it to the rolling line |

|

|

On-site characteristics |

Characteristics of building structure |

The plant is relatively spacious |

|

Features of the equipment |

The main equipment is the vaporization cooling heating furnace system. It is mainly divided into: water supplement system, circulation system, sewage system, cooling water system, complex structure, vibration, and part of the equipment is in the basement. |

|

|

Characteristics of the environment |

Indoor environment, with a lot of steam, very high temperature, humidity, vibration, gas, flammable, explosive and toxic gas. |

|

|

Lamp requirements |

① The ceiling lamps are sealed to at least IP65, and have anti-vibration and anti-corrosion design. ② Lamp fittings (sealing ring, etc. can withstand high temperature). ③ The lighting equipment close to the furnace body such as corridor lighting, platform lighting, etc. needs to use explosion-proof lamps. ④ Electrical appliances have high temperature resistance and are easy to use inductive ballasts. |

|

|

Recommended lamps |

CES-EX-LN02 explosion-proof LED linear lamp has extremely sturdy circuit devices and completely sealed electrical components, and has IP66 and WF2 anti-corrosion grades. In addition to being able to withstand severe vibration and vibration, it can also prevent any corrosion that may cause electrical failure . Hazardous areas Linear lights also have multi-voltage capabilities. They can operate under 100-277 VAC, 50/60Hz, without additional special ballasts. |

|

- Rolling line

|

Position Title |

Rolling line |

|

|

The function and role of the post |

Rolling slabs into strips of different thicknesses |

|

|

On-site characteristics |

Characteristics of building structure |

The plant is relatively spacious |

|

Features of the equipment |

(Main equipment: dephosphorization box, vertical roll, roughing mill, hot coil box, flying shear, finishing dephosphorization machine, small vertical roll, finishing mill, laminar cooling roller table, underground coiler), there are many links, Continuous operation, vibration. |

|

|

Characteristics of the environment |

Indoor operations are corrosive and have certain vibrations. The equipment should be flushed with water. |

|

|

Lamp requirements |

① The ceiling lamps are sealed to at least IP65, and have anti-vibration and anti-corrosion design. ② Electrical appliances have high temperature resistance and are easy to use inductive ballasts. ③ It is recommended to adopt a split installation, and place the electrical part on the side of the visitor channel, where the principle is hot steam dense area. |

|

|

Recommended lamps |

The internal electrical components of the CEX-EX-LN explosion-proof LED linear lamp are completely sealed and can work underwater (3 meters, we have a long-term hydraulic test and heavy pressure test). The light source room is completely separated from the power source, effectively avoiding electrical sparks. The impact of components or optical components, the hazardous area linear lamp has IP66 waterproof rating, 10mm thick tempered glass + ADC12 and 6063 aluminum housing, shock and vibration resistance, can withstand 7J impact, suitable for salt water and corrosive environments. |

|

- Finishing

|

Position Title |

Finishing |

|

|

The function and role of the post |

1. Reshape the strip. 2. Adjust the length, width, and weight of the strip according to customer needs. |

|

|

On-site characteristics |

Characteristics of building structure |

The plant is relatively spacious |

|

Features of the equipment |

Equipment (including uncoiler, straightening machine, cutting machine, hydraulic shears), there is vibration, there are large motors and control parts, there are electric meters for motor operation, etc. There are many occasions where there are camera monitoring. |

|

|

Characteristics of the environment |

Indoors, it is corrosive, the temperature is high, and there is a certain amount of vibration. |

|

|

Lamp requirements |

① The ceiling lamps are sealed to at least IP65, and have anti-vibration and anti-corrosion design. ② Lamp fittings (sealing ring, etc. can withstand high temperature). ③ Electrical appliances have high temperature resistance and are easy to use inductive ballasts. ④ It is recommended to adopt a split installation, and place the electrical part on the side of the visitor channel, in an area with dense hot steam. |

|

|

Recommended lamps |

CES-EX-GB explosion-proof high bay light is a high-power explosion-proof lamp. The flameproof shell design can prevent the electric spark generated in the lamp from being transmitted to the outside. Its protection level is IP66/67, can withstand 7J shock and vibration, and its explosion-proof performance is better than HPS Explosion-proof lamps, metal halide lamps, halogen lamps, etc. are more reliable. The wiring cavity, power supply cavity, light source cavity and other cavities are independently divided into cavities. The explosion-proof performance is reliable and it is very corrosive and high-temperature environment. |

|

- Curl and pack

|

Position Title |

Coil library |

|

|

The function and role of the post |

Roll the flattened steel and pack it out of the warehouse. |

|

|

On-site characteristics |

Characteristics of building structure |

The steel coil warehouse has a large area. |

|

Features of the equipment |

The main equipment is a coiler and a crane for packing and storing carbon steel and stainless steel after sorting and sorting. |

|

|

Characteristics of the environment |

Indoors, the temperature is high and there is a certain amount of vibration. |

|

|

Lamp requirements |

① The ceiling lamps are sealed to at least IP65, and have anti-vibration and anti-corrosion design. ② Lamp fittings (sealing ring, etc. can withstand high temperature) ③ Electrical appliances have high temperature resistance and are easy to use inductive ballasts. ④ It is recommended to adopt a split installation, and place the electrical part on the side of the visitor channel, in an area with dense hot steam. |

|

|

Recommended lamps |

The unique installation module design of CES-EX-GB02 explosion-proof high bay light enables the light to achieve 90-degree aiming and efficient ballast. The device has EOL protection function, which can eliminate potential accidents. Each cavity, such as the wiring cavity, the power supply cavity and the light source cavity, is independently divided into cavities, and the explosion-proof performance is reliable. The IP66/67 protection level, durability, anti-vibration and impact resistance make the lamp more efficient and safer. |

|

- Roller repair room

|

Position Title |

Roller room |

|

|

The function and role of the post |

Check and trim the accuracy of rolls, store all kinds of rolls |

|

|

On-site characteristics |

Characteristics of building structure |

The workshop is spacious. |

|

Features of the equipment |

The main equipment is driving. |

|

|

Characteristics of the environment |

Indoors, there is a certain amount of vibration. |

|

|

Lamp requirements |

① The ceiling lamps are well sealed and have anti-vibration design. ② It is recommended to use split installation, and place the electrical part on the side of the visitor channel to reduce the weight of the lamp. |

|

|

Recommended lamps |

The CES-EX-SF explosion-proof LED canopy lamp has a sturdy shell, and the internal electrical components are completely sealed. It has the characteristics of impact resistance, vibration resistance and corrosion resistance. The PC mask diffuses to reduce glare, can withstand 6J pressure, and the maximum temperature does not exceed T4, which is much lower than the traditional The temperature of the lamp. Energy efficiency is 80% higher than that of metal halides. The service life is up to 50,000 hours, making it maintenance-free for almost many years. |

|

- Electrical room

|

Position Title |

Electrical room |

|

|

The function and role of the post |

The control center of electric equipment such as motors in the hot rolling area. |

|

|

On-site characteristics |

Characteristics of building structure |

Spacious workshop |

|

Features of the equipment |

The main equipment is electrical cabinets and control cabinets. |

|

|

Characteristics of the environment |

Indoor, conventional environment. |

|

|

Lamp requirements |

① No special requirements. ② Conventional fluorescent lamps or ceiling lamps can satisfy lighting requirements without glare. ③ The choice of lamp type depends on the structure and height of the workshop plant. |

|

|

Recommended lamps |

CES-EX-LN-02P explosion-proof linear light design replaces the traditional explosion-proof fluorescent lamp, explosion-proof tri-proof lamp, anti-glare-micro optics can reduce direct visual contact with the light source. The slim and streamlined design of linear lights in hazardous areas allows access to limited spaces at a low installation height, and is IP66 waterproof and dustproof, with a life span of more than 50,000 hours. |

|

Shenzhen CESP Co., Ltd. focuses on the field of special industrial lighting. It is a high-tech enterprise integrating design, R&D, production and sales. The complete management team covers the lighting fields of China's electric power, metallurgy, oil refining, railways, large industrial and mining enterprises, marine ships, etc. Provide professional lighting supporting solutions, and also provide advanced technical support and product supporting services for internationally renowned companies.

At the same time, CESP is also ATEX certified led manufacturer, UL led manufacturers and IECEX certified led supplier. The company’s products include explosion proof LED flood light, explosion proof led highbay light, explosion proof led canopy light, explosion proof led linear light, explosion proof portable hand light etc. If you have explosion-proof lighting needs, you can click on the page to contact us, or call our hotline +86-755-83509822.

Container Lighting Solutions

Containers, also known as cargo loading, can not only be used to transport goods by sea or land, but are also often used as simple mobile houses; the existing lighting system of house containers usually installs lights on the top of the house container.First of all, we must understand that the container has several advantages:

- Introduce modern home furnishing elements, taking a single cabinet as a unit, which can be combined and superimposed in any combination. The performance of sealing, sound insulation, fire prevention, moisture resistance, heat insulation, etc. should be better.

- The overall structure, welded and fixed, is stronger and safer, more wind-resistant, and more earthquake-resistant. It will not fall apart or collapse in the event of typhoon, earthquake, ground subsidence and other disasters.

- The whole box can be hoisted, no concrete foundation is needed, 15 minutes installation, 1 hour check-in, and it can be used when it is connected to the power supply.

- Floors, walls, ceilings, water and electricity, doors and windows, exhaust fans and other one-time decoration, permanent use, energy saving, environmental protection and beautiful.

- The design is more user-friendly, living and working are more comfortable, and the number of rooms can be increased or decreased at any time, which is convenient and flexible.

- The relocation does not need to be dismantled. The items in the room can be moved with the box without loss. It can be hoisted and moved more than a thousand times, which is convenient and saves money.

- After the decoration of the container, the inner area is about 13 square meters, and each container is 12,000 yuan, which is nearly 900 yuan per square meter. Compared with the current housing prices in many places, it is very cheap.

In 2018, the US "Business Weekly" listed 20 important inventions that are most likely to change our way of life in the next 10 years, and the container house ranked 19th. The US "Business Weekly" said: "Using containers to rebuild houses, this invention can solve the housing problem of hundreds of millions of poor families. At present, a container house with a usable area of 30 square meters sells for less than 10,000 US dollars."

According to statistics, there are about 18 million steel containers floating on the sea or on roads to transport goods in the world. In addition, there are about 2 million containers in idle state. All containers will eventually be eliminated. However, they are very sturdy, because they must be able to carry a weight of 30 tons to sail at sea. If they can be reused effectively, it will not only save costs, but also save resources and protect the environment. For the port, container transportation is one of the main transfer methods of the port.

Except for dangerous goods containers, although the probability of fire in the port loading, unloading and storage of ordinary goods containers is low, there are still many factors that lead to the occurrence and spread of fires. These complex factors are intertwined, making it very difficult to save.

- Possible causes and cases of container fires

- Burning caused by carton

The cargo in some containers is packed by cardboard. These packaging cardboards are spontaneously combustible substances, and they are usually made of raw materials such as rice straw, wheat straw, and reeds. These raw materials are grass-like plant fibrous substances, which are composed of cellulose, hemicellulose, lignin and a small amount of pectin, resin and wax. Under the condition of high water content, biological, physical and chemical can occur. Change and release a lot of heat. The container has a certain degree of airtightness. In summer, the temperature inside the box can reach 50. When the temperature difference is large, the wall of the box will “sweat” and water will accumulate at the bottom of the box. In addition, the heat generated by the products packaged in the cardboard will also cause the cardboard to burn. At 19:00 on September 7, 2004, the Liberian container ship "China Ocean Hong Kong", which was parked at the terminal of Shanghai Port Container Waigaoqiao Branch, was heated by unqualified rechargeable nickel-metal hydride batteries loaded in a container in the cabin. , The heat cannot be dissipated in time, and the heat gathering effect will ignite the cardboard packaging materials, causing a direct loss of RMB 3.1 million.

- Smoldering and spontaneous combustion of cotton and hemp

Packed cotton, whether in transit or in stacks, will not spread quickly after being caught in a fire, sometimes due to insufficient oxygen supply. The combustion is often carried out slowly in a local or small area. In this kind of combustion, no flames or smoke can be seen, and it is in a smoldering state. It can last for several days or even dozens of days without being easily noticed. But when the smoldering cotton suddenly encounters air convection, not only can the smoldering cotton become completely burnt quickly, but it can also cause the mixture of carbon monoxide and air to deflagrate. Cotton can also ignite spontaneously. The reason is that cotton will inevitably be infected with a large number of microorganisms during the process of picking and processing. Under humid conditions, microorganisms are easy to grow and reproduce, and when the water content in the cotton fiber is appropriate, the microorganisms can grow and reproduce rapidly, secrete cellulase and acid, generate heat, and make cotton moldy and change color. Over time, if the accumulated heat does not dissipate, and the temperature gradually rises, spontaneous combustion will occur. Hemp fiber plants such as jute, hemp, sisal and cotton have similar characteristics, and they also have smoldering and spontaneous combustion.

- Oxidation and spontaneous combustion of chemical products caused by heat and moisture

Containers are generally stacked in open yards, so they have to withstand the sun and rain. Especially in summer, the highest temperature in some areas can reach more than 40 ℃, while the surface temperature is higher. Under such high temperature, the temperature inside the container can reach 50°C. At this time, some chemical products in the container, such as high-nitrogen fertilizers, fish meal, etc. will be easily thermally decomposed and oxidize and spontaneously combust. In addition, the "sweat" of the tank wall will also cause the chemical products to be damp and cause oxidation and spontaneous combustion. At 13:00 on July 16, 2004, the sodium disulfite in the container of the "Nantai 27" vessel berthed at the No. 5 anchorage of Guiyu West, Shantou Port, Guangdong Province, China was spontaneously ignited due to moisture, causing 3 people to be injured and a direct economic loss of RMB 2.068 million yuan.

- Personnel operating errors cause fire

Improper operations such as container maintenance and cargo disinfection can also cause fires. The container is inevitably damaged during transportation. If the maintenance personnel accidentally splashes on combustibles during electric welding and gas welding operations, it will cause a fire; when performing operations such as disinfection of flammable and explosive goods in the container, violation of relevant regulations Improper handling can also cause fires. At about 18:40 on July 10, 2002, workers at the Fuyong dock in Shenzhen, China, improperly detonated the container while disinfecting the incoming container that had just entered the terminal, causing another 13 adjacent to the fire and explosion container to contain scrap hardware and waste. Plastic containers were also ignited by the fire. Three dockers were burned and seriously injured.

- Lightning strikes and fires

The open-air cargo yard where the containers are stacked is a large open area, which is extremely vulnerable to lightning strikes. If there is no lightning protection device installed in the open yard, the container may be struck by lightning and catch fire.

- External fire and man-made arson

In order to facilitate mechanized loading and unloading, container transportation packs the loose goods to be transported in boxes in advance. If the goods are not inspected before packing, it is possible that the kind of fire touched during transportation will be entrained into the box, which may cause a fire. In addition, it has been found from the investigation of fire causes over the years that man-made arson accounts for a certain proportion, so man-made arson may also be one of the causes of container fires.

- Container fire spreading method

Container fires will spread mainly through heat conduction, but also through heat radiation, explosion splashing, and melting of combustibles.

- Heat Conduction

There are three ways to transfer heat energy in a fire, and heat conduction is one of them. Most of the existing container manufacturing materials all over the world are aluminum alloy and steel plate. This kind of metal material has a large thermal conductivity. Therefore, once a certain container catches fire, the heat energy will first be transferred to the adjacent container through heat conduction. As the heat accumulates, the combustible materials in the adjacent container will be ignited. If the lower container catches fire first, the load-bearing capacity of the upper container will be reduced due to thermal deformation, and the upper container will easily collapse, and the combustibles loaded on it will be ignited after it is scattered.

- Thermal radiation

When the fire reaches a certain scale, the spread of the fire through heat radiation will become more significant. With the expansion of the fire, the heat radiation of the fire source to the nearby combustibles is also increasing. When the radiant heat increases to a certain extent, the combustible materials at a certain distance from the fire source will be ignited by receiving enough radiant heat flow.

There are many types of cargo loaded in containers, and the heat transferred through radiation is blocked by the container shell, so it is difficult to determine the minimum heat flow value for combustible materials ignited by radiation.

- Explosion splash

Explosion refers to a process in which physical energy and chemical energy change rapidly in a certain space or state, and in this process the resident energy in the system is rapidly converted into kinetic energy, mechanical energy, light and thermal radiation. Therefore, explosion can also be said to be an extremely rapid process of physical or chemical energy release. After a fire occurs in a container, the flammable gas generated cannot be fully burned or released, and higher temperature and pressure will accumulate in the container, which may cause an explosion because it is not easy to dissipate heat and release pressure. Some explosive fragments, such as flaming steel bars, burning goods, etc., will further expand the fire if they fall on other combustible materials.

- Melting of combustibles

Rosin, glass, beeswax, pitch and other substances do not have a certain melting point and freezing point, and are called amorphous. Since there is no melting point or freezing point, it changes from hard to soft during the endothermic process, and then gradually becomes liquid. During the entire melting process, the temperature continues to rise. In a container fire, non-crystalline goods melt and become liquid after absorbing a lot of heat. The container is usually not completely sealed. If these high-temperature liquids flow through the gaps to other combustibles, the fire will spread.

- Factors for the expansion of container fires

- The fire-fighting facilities of the container yard are not sound

The unsoundness of fire-fighting facilities in container yards has both objective and subjective reasons. The objective reasons are mainly due to geology and the construction method of the wharf, which make it difficult to lay fire hydrants and pipelines on the wharf, or the setting of fire water sources is unreasonable, and the design of fire water consumption is not compatible with actual needs. Due to the limited geographical location of ports, most port container yards are reclaimed from the sea, and settlements will occur to varying degrees over time. The fire-fighting pipelines laid under the large slabs of the container terminal-gravel concrete) caused serious leakage of pipelines due to uneven settlement, and it was very difficult to repair under the large slabs of the yard. In this case, most ports have closed the pipeline Valve approach to prevent the waste of water resources and protect the yard.

The lack of special fire protection regulations for container yards is also one of the factors restricting the perfection of fire protection facilities in container yards. At present, China's container yard is mainly designed in accordance with the national standard "Code for Fire Protection Design of Jianzhu" (GB 50016-2006), but the standard does not clearly stipulate the design parameters of the fire water supply of the container yard, resulting in the actual design and use process Different designers use different water supply rates. This is likely to cause the designed fire fighting water consumption to be incompatible with actual needs. If the designed water supply is too large, it will cause a waste of investment, and if the designed water supply is less than the actual need, once the yard catches fire, it will greatly affect the fire fighting effect.

On the other hand, the unsound fire-fighting facilities are also caused by the subjective reasons that the relevant departments do not pay attention to. Because the probability of fire in the container of ordinary goods other than dangerous goods is low, this makes some relevant personnel paralyzed and neglects the daily inspection and maintenance of fire-fighting equipment.

- The alarm is not timely and the effectiveness of fire fighting is poor

Containers are often stacked in multiple layers, generally 4-5 layers high. If a certain container inside the yard fires first, it will be difficult to find out from outside the yard in time, and the fire may have developed to a certain scale when it is discovered. Moreover, since the fired container may be inside the yard, it is difficult for the sprayed fire-fighting water to effectively act on the fired container box. In addition, container fires are often caused by the cargo inside the container. Even if a certain container outside the yard catches fire first, due to the tightness of the container and the densely packed cargo, the firefighters will not be able to effectively extinguish the fire. The surface of the container can be cooled by jet water jets. The thermal conductivity of metal will quickly spread the fire to the surrounding area, increasing the difficulty of fire fighting.

- The container has good sealing performance, which may cause an explosion in the event of a fire

The container has good airtightness. Therefore, once a fire occurs inside the container, the flammable gas generated cannot be fully burned or released, and higher temperature and pressure will accumulate in the container, which may cause an explosion. Because the explosion is a violent physical and chemical change, accompanied by the generation of light, heat, and pressure, and causes dissociation and hypoxia in the explosion area, it has a great destructive effect. The fired objects splashed by the explosion will not only expand the fire area of the fire, but also directly affect the personal safety of firefighters. In order to avoid casualties, firefighters often have to temporarily evacuate or stay away from the burning container to carry out fire fighting, which will affect the fire fighting effect and delay the fire fighting opportunity.

- The seaside wind speed is relatively high

The container yard is open and built near the sea, so the wind in the yard is relatively high, and sometimes typhoons may occur. Such weather conditions will not only promote the spread of fires, but are also not conducive to fire fighting.

Through the above analysis of container fire hazard and previous fire cases, it can be known that it is difficult to extinguish a container after a fire occurs and the water demand is large. Therefore, the container yard must be equipped with stable and reliable fire-fighting facilities and relatively stable safety facilities, such as anti-corrosion and dust-proof transportation. Belts, explosion-proof lamps with high safety, cranes with strong bearing capacity, etc.

Shenzhen CESP Co., Ltd. focuses on the field of special industrial lighting. It is a high-tech enterprise integrating design, R&D, production and sales. The complete management team covers the lighting fields of China's electric power, metallurgy, oil refining, railways, large industrial and mining enterprises, marine ships, etc. Provide professional lighting solutions, At the same time, it also provides advanced technical support and product supporting services for well-known international companies. CESP's products have obtained the North American UL certification, the European Union ATEX certification and the international IECEX certification, It is very suitable for general area lighting installed in wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor or indoor installations, as well as places where flammable vapors, gases, combustible dust, fibers or flying exist Use in hazardous areas.

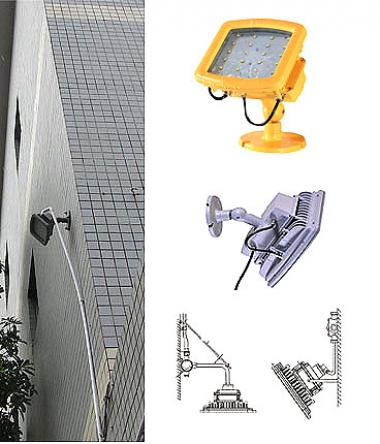

CES-EX-J series explosion-proof LED floodlights are safety-increased and flameproof enclosure lights. The shell is made of high-strength aluminum alloy + tempered glass, which has stronger vibration and impact resistance. The designer took into account the heat dissipation performance of the explosion-proof lamp, and designed the back of the lamp to have a corrugated effect, so that the efficiency and service life of the lamp tube can withstand higher mechanical strength and temperature changes. This hazardous area LED floodlight complies with UL1598A marine-grade certification. The sealed structure prevents water vapor from entering the lamp body. It complies with IP68 and WF2 standards and is very suitable for humid salt water and corrosive environments. The floodlighting device has passed the precise light distribution design and good optical system, coupled with the excellent 3D heat dissipation structure design, so that this high-power hazardous area floodlight has the best lighting level and the lowest maintenance cost, and There are a variety of installation methods and a variety of luminosity for users to choose, It is very suitable for use in hazardous environments such as local lighting, low-rise lighting, stairwells, gantry and walkways, craft skids, cable tray areas, low-overhead marine void spaces, paint and solvent storage rooms, gas stations, offshore oil and gas platforms, and chemical industries.

If you have related lighting needs, you can contact us directly, or call our hotline, we will provide quality services and lighting solutions that meet your needs.

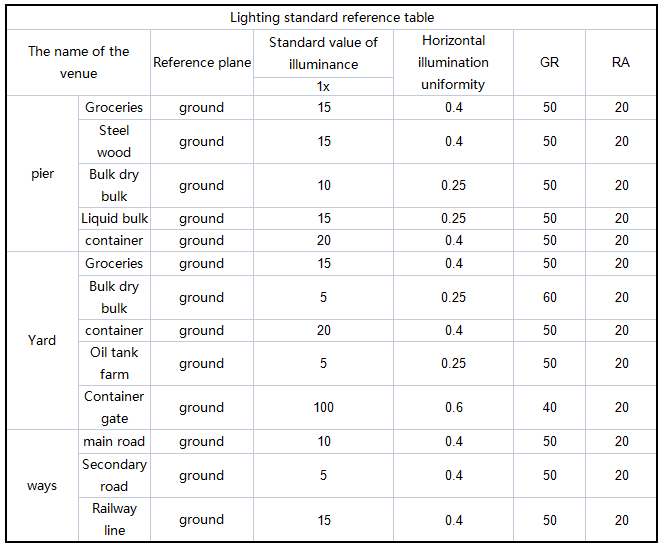

Port Terminal Lighting Solution

The port is an important transportation hub and a window to realize an export-oriented economy. China’s major ports have occupied an important position among the world’s ports. The container throughput has been ranked first in the world for many years, becoming the world’s largest port and container throughput. , The fastest growing country. As the economy continues to grow, energy conservation, emission reduction, and efficiency improvement have become urgent requirements for China and the world. For example, the power consumption of lighting in the Shanghai International Port Area is as high as 5.94 million KWh. Port companies have always been large energy consumers in the transportation industry. Energy saving has become one of the important means for port companies to enhance their international competitiveness in the new era. Therefore, the solution to port lighting Is the top priority.

- Lighting standards

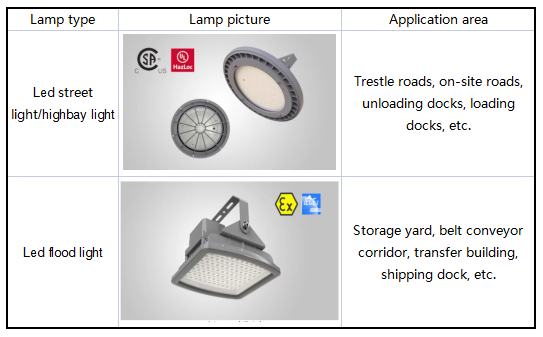

The dock lighting standards for different purposes will be different. The following only gives the lighting standards for general areas.

The wharf is located along the river and the ocean, and the air humidity is relatively high, and the erosion of salt fog and oceanic climate is serious. In addition, port refineries, also known as seaside oil refineries, are usually flammable and explosive, but because they are close to the sea, corrosion prevention needs to be considered. Especially near the southeast coastal areas of China, there are more typhoons and heavy rains, and the climatic conditions are harsh. At the same time, in the docks that transport bulk goods (coal or grain), there is the diffusion of fine particles, which will cause serious dust pollution. These are all factors that need to be considered when designing lighting. The lamps and lanterns used in the dock should meet the following requirements:

- High power: Because the height of the gantry crane is about tens of meters, it has the characteristics of wide adaptability and large working range. In order to meet the illumination requirements of the working surface, the power of general fluorescent lamps should be above 400W, and the power of LED lamps should be Above

- Long life: Due to the high height of the gantry crane, it is not easy to repair the lamp after it is damaged, so it is necessary to install a lamp with a long service life.

- Safe and reliable: There are many types of goods on the port terminal and the environment is complicated. It is necessary to configure safe and reliable lighting fixtures to ensure the lighting safety of the port terminal and prevent fire incidents caused by the short circuit of the lamps.

- High protection level: The port is in a humid environment all the year round, so the requirements for the waterproof and dustproof level of the lamps are relatively high. The lamps with high protection level can prevent water vapor from entering the lamp body and prolong the service life of the lamps. The lamp shell is made of high-quality aluminum alloy die-casting, and the outer surface is treated with high-voltage electrostatic spray, which improves the overall anti-corrosion level of the product. The whole lamp has an independent heat dissipation system and the drive is external. Waterproof, so that the protection level of the lamp reaches IP65, without fear of the humid environment of the port terminal. The anti-corrosion level of lamps needs to reach the WF2

- The light source and accessories are easy to replace.

- Lamp parts have good anti-corrosion performance.

- The lamp is installed stably and has good wind resistance.

- Unless otherwise specified by the owner unit, lamps must comply with the latest national standards (GB), International Electrotechnical Commission (IEC) standards and International System of Units (SI) standards.

- Selection of lamps

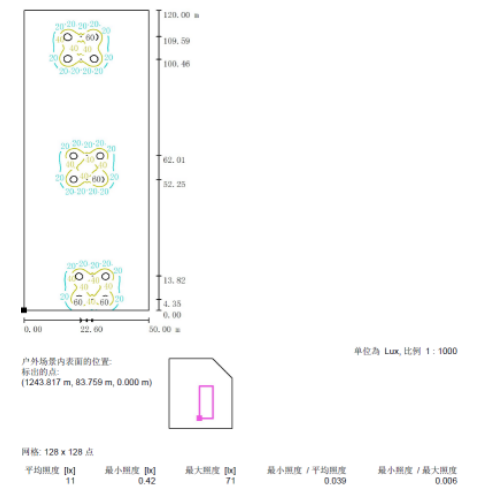

- Simulation lighting

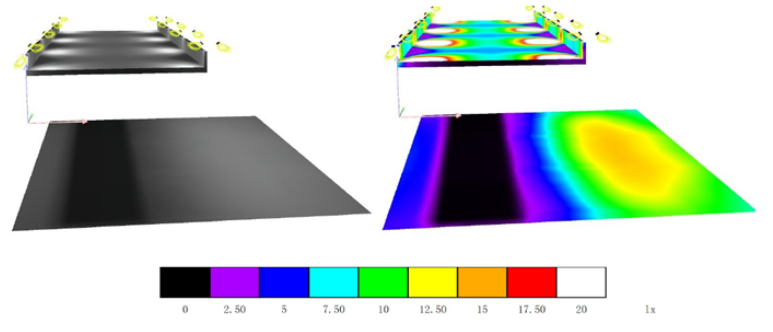

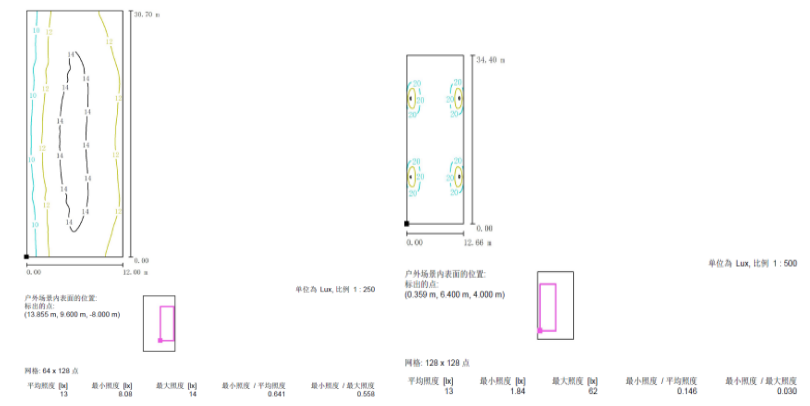

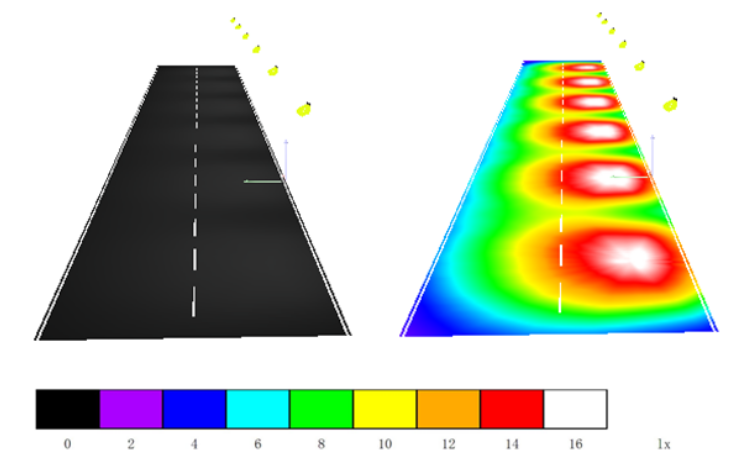

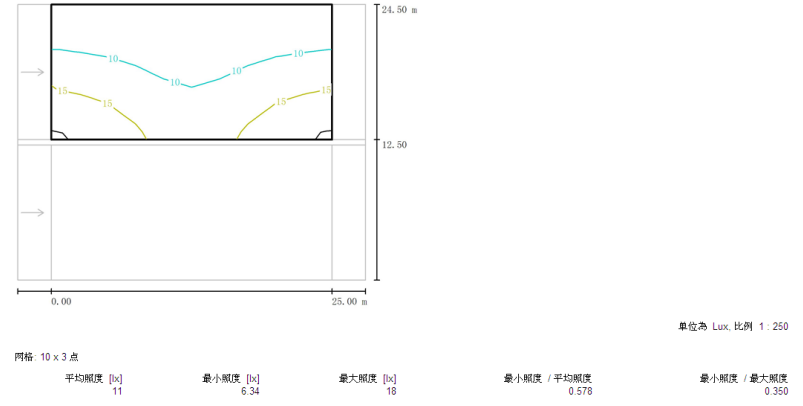

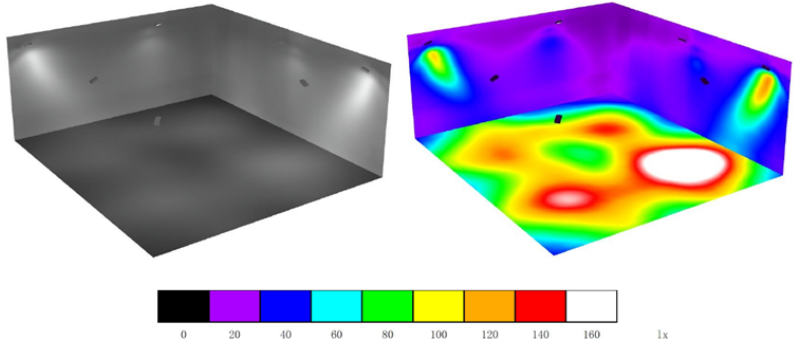

In the simulation, the coal operation terminal is taken as an example, and the simulation is carried out in various scenarios. The simulation results are as follows:

- Ship unloading dock

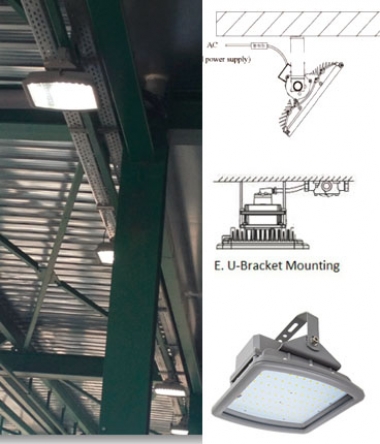

The unloading dock should not only illuminate the belt conveyor belt above, but also illuminate the side road. The lamps are installed on the brackets outside the conveyor corridor.

3D renderings and pseudo-color images

Calculation results

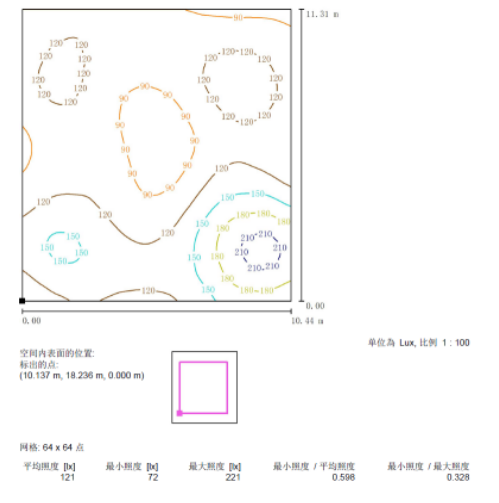

- Trestle

The trestle bridge is mainly for road lighting, so street lights can be used.

3D renderings and pseudo-color images

Calculation results

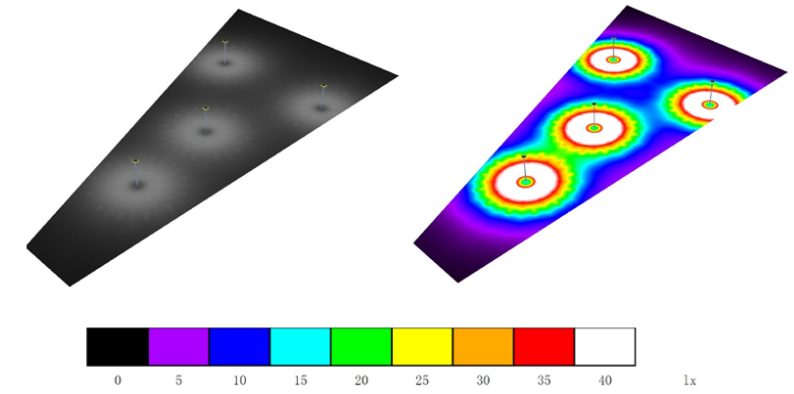

- Transfer building

Because of the power limitation of the belt conveyor, the belt length is limited, or the direction of the belt conveyor needs to be changed, the transfer building needs to be transferred. Because the transfer building is operated by humans, the illuminance requirements are high, and it needs to reach more than 100lx.

3D renderings and pseudo-color images

Calculation results

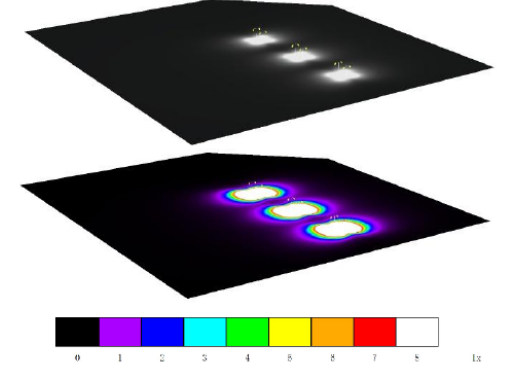

- Yard

The storage yard is generally a storage area for items, and the common lighting method is high-pole lighting.

3D renderings and pseudo-color images

Calculation results

- Loading dock

Ship loading docks generally illuminate the ship’s deck and navigation channels in inland river basins. Street lights or floodlights can be used.

3D renderings and pseudo-color images

Calculation results

- Pictures of the scene

Loading dock

Unloading dock

Shenzhen CESP Co., Ltd. focuses on the field of special industrial lighting. It is a high-tech enterprise integrating design, R&D, production and sales. The complete management team covers the lighting fields of China's electric power, metallurgy, oil refining, railways, large industrial and mining enterprises, marine ships, etc. Provide professional lighting supporting solutions, and also provide advanced technical support and product supporting services for internationally renowned companies. CESP’s products have obtained North American UL certification, EU ATEX certification and international IECEX certification, which are very suitable for general area lighting installed in wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor or indoor installations. And use in places where flammable vapors, gases, combustible dust, fibers, or hazardous areas exist in flight.

The CES-EX-GB02 series explosion-proof high bay lamp body has a protection level of IP66 and an anti-corrosion level up to WF2. It is equipped with a corrosion-resistant high-strength aluminum alloy shell, which has good durability, vibration resistance, impact resistance and marine corrosion resistance.It is very suitable for salt water and corrosive environments. Although this explosion-proof lamp is a high-power LED high bay lamp, the power supply adopts wide voltage processing, can work under 100-277 VAC, 50/60Hz, and realizes constant current output. It has short-circuit and over-voltage protection functions, which greatly extend the lamp Service life. The explosion-proof LED high bay light shell is specially designed for heat dissipation, thereby improving the efficiency and service life of the LED lamp. The tempered glass cover is anti-glare design, with high illumination uniformity, no ghosting, effectively avoiding glare, spot and aperture, and does not damage the light efficiency . It is suitable for various low ceilings, platforms, high ceilings, high sheds and other places as solid lighting.

The CES-EX-J series of explosion-proof floodlights adopt a sealed structure with high waterproof and anti-corrosion performance. They comply with UL1598A marine certification and are very suitable for salt water and corrosive environments. Precise light distribution design and good optical system, coupled with excellent 3D heat dissipation structure design, make this high-power hazardous area floodlight, compared with traditional explosion-proof lighting fixtures, have the best lighting level and the lowest maintenance cost . As an increased-safety and shell-protected explosion-proof lamp, it can be used under T4 ambient temperature, and the shell is made of die-cast aluminum. The designer took into account the heat dissipation performance of the explosion-proof lamp, and designed the back of the lamp with a corrugated effect. It can work under the environment of -40℃-55℃, with longer life span, which can reach more than 50,000 hours. Obtained UL844/ATEX/IECEX certification, and guaranteed a five-year warranty, this makes this hazardous area floodlight very suitable for local lighting, low-level lighting, stairwells, gantry and walkways, craft skids, cable tray areas, low-overhead ocean void spaces, paint and solvent storage rooms, gas stations, offshore oil and gas platforms , Chemical industry and other hazardous environments.

CESP also has lighting solutions for offshore drilling and oilfield joint stations. If you have related lighting needs, you can contact us directly or call our hotline. We will provide quality services and lighting solutions that meet your needs.

Why does sulfur dust explode and how to prevent it ?

Ordinary natural gas purification plant has an annual sulfur production capacity of 240 x 10' t. The sulfur molding process adopts wet molding. The product is granular sulfur with a diameter of 3 ~ 5mm, which is stored in two sulfur silos with a storage capacity of 5.7×10°t. Transport to the car or train loading building by conveyor belt. Sulfur particles produce a large amount of sulfur dust in the process of transportation, transportation, and loading. Dust monitoring and suppression systems are set up to control the dust hazards. However, sulfur dust also has the risk of explosion under certain conditions.

- The physical and chemical properties of sulfur

Sulfur is a secondary flammable solid, non-toxic, CAS number 7704 -34-9; powdered sulfur is light yellow powder, specific gravity 1.96, bulk sulfur is light yellow crystals, specific gravity 2.05, melting point 112.8 ~120 ℃, boiling point 444.6 ℃, The flash point is 207.20 ℃. Easily soluble in carbon disulfide, insoluble in water, slightly soluble in ethanol and ethers. The burning temperature of sulfur is generally 248 ~ 261 ℃, and the burning temperature of powdered sulfur is only about 190 ℃, and it burns with a blue flame; when it is stained with iron sulfide, iron oxide (rust), engine oil, metal powder, carbon powder and oxidant substances , It is easy to ignite sulfur and cause fire; sulfur dust in the air or mixed with oxidant is easy to burn, and even cause dust explosion.

- Hazard Analysis of Sulfur Dust Explosion

- Sulfur combustion characteristics

Due to the different molding methods, sulfur is in the form of powder, granules, flakes, or lumps. It exhibits different combustion performance under different conditions and states. When the solid particle size is small, it exhibits flammable characteristics. The product of sulfur combustion is mainly sulfur dioxide, and its combustion heat is 300kJ/mol. Sulfur can cause fires under heat, impact, friction, etc. It will generate static electricity in the process of crushing, grinding, storage and transportation, causing spontaneous combustion and explosion.

- Sulfur dust explosion conditions

The explosion characteristics of sulfur dust are affected by a variety of factors, and there should be "5 conditions" to cause a sulfur dust explosion: combustible dust, dust cloud, ignition source, combustible material, and limited space.

- Hazard Analysis of Dust Explosion in Sulfur Storage and Transportation System

Combining the process characteristics and safety characteristics of the sulfur storage and transportation system of the purification plant, the hazard of sulfur dust explosion during the storage and transportation of the purification plant is analyzed.

- Friction, impact sparks. During the transportation process of the sulfur particles, the sulfur particles and its storage and transportation equipment hit the sparks. When the sulfur particles violently collide or rub against each other, the sparks generated by the impact or friction fall off high-temperature solid particles. Tests have shown that if the diameter of the sparks is 0.1 ~ 1 mm, its energy can reach 1.76 ~ 1 760 mJ, which may ignite sulfur dust. The static electricity generated by the friction between the particles, dust and the conveyor belt and the particles and dust, under appropriate conditions, can have an electrostatic voltage of several to tens of thousands of volts, and the energy generated is far greater than the minimum ignition energy of sulfur particles.

- Spontaneous combustion of ferrous sulfide on the surface of the equipment. The carbon steel equipment is made of materials that are prone to produce ferrous sulfide, and it will produce ferrous sulfide on the surface in long-term contact with sulfur; an appropriate amount of water has a positive catalytic effect on the spontaneous combustion process of ferrous sulfide, and the initial self-heating temperature of FeS can be reduced from 140.93°C when there is no water. To 40 ~ 60 ℃ when water is contained; when the humidity in the air increases, the self-heating performance of ferrous sulfide will gradually increase; self-heating and spontaneous combustion of ferrous sulfide occur. When the heat is released to a certain degree, it can form an open flame to ignite the surrounding flammable Substance: As the air flow increases, the heating rate of ferrous sulfide gradually increases.

- Electric sparks caused by electrical equipment failure.

- The equipment generates heat due to friction due to lack of lubrication at the mechanical running parts.

- Analysis of Dust Explosion Hazard in Storage and Transportation

- Storage system

- Bulk sulfur blanking point. The sulfur material falling from the top to the bottom by its own gravity at the blanking point is likely to cause dust to fly, so that the sulfur dust and the air are fully mixed to form a dust cloud, which is easy to cause combustion and explosion.

- A large number of sulfur particles are piled up. It may come into contact with oxygen in the air to produce an oxidative exothermic reaction. If the heat is not sufficiently dissipated, the temperature will increase and cause spontaneous combustion.

- Sulfur dust deposited in pits, depressions, ditches, dead ends and equipment surfaces. If these dusts are not removed in time, it is easy to cause dust to fly and form suspension explosion conditions during the cleaning process.

- There may be combustible gases such as hydrogen sulfide in the sulfur silos. These gases are heavier than air. There is also a fire and explosion hazard due to the accumulation of combustible gases at the bottom of the silo and underground corridors.

- Conveyor system

- Conveyor belt. Due to the sulfur produced by the wet molding process, there are some small fine powder particles of sulfur, and some of the sulfur particles adhere to the surface of the transfer belt during the transportation process, and fall due to the vibration of the belt and the change in tension, causing the fine powder sulfur to be scattered along the belt. build up. When the sulfur dust reaches a certain thickness, it can easily cause smoldering.

- Color steel ceiling. Sulfur powder falls from the return belt and accumulates more on the roof. When the surface temperature is high, the moisture continuously evaporates, acidic sulfur powder and corroded iron sheet are easy to generate ferrous sulfide and spontaneously combust in the high temperature and humid environment, and will reduce the sulfur in the interlayer. The powder ignites.

- Power cable. When the spontaneous combustion of ferrous sulfide causes the sulfur in the cracks of the roof to liquefy around the flame, the sulfur with the flame flows into the cable rack under the shed, which will cause the cable rubber to burn and cause more serious combustion and explosion accidents.

- Friction static. The static electricity accumulated during the operation of the belt conveyor may cause the sulfur to burn and explode.

- Loading system

- The loading equipment corrodes and catches fire. For example, the buffer bin and screw feeder are corroded and perforated, the ram tie rod joints have been corroded and broken repeatedly, and the roof of the loading building has been corroded and caught fire.

- Buffer storage gate. Repeatedly automatically open and close for batching weighing cycle operation, it is easy to produce friction static electricity and cause sulfur burning.

- Bulk sulfur blanking point. Bulk sulfur quickly slides into the container from the height of the loading building. The friction and impact between the sulfur particles generate strong static electricity. After the formation of a dust cloud, static electricity and electric sparks can easily cause explosion accidents.

- Car loading yard. Sulfur dust is easy to form during loading, especially in the summer when the vehicles are packed tightly, and during the frequent parking and starting of the car, the sulfur dust is more serious and easy to cause spontaneous combustion.

- At the guide trough. During the transportation process, mechanical vibration and friction and collision between particles are prone to produce suspended sulfur dust, which is extremely easy to burn and explode.

- Sulfur dust deposited on heating surfaces such as lighting devices and hot surfaces of mechanical equipment may smolder after being heated for a period of time within a certain layer thickness range (such as 10 ~ 20mm).

- Emergency measures to be taken in the event of fire and explosion hazards

Through the analysis and investigation of typical dust explosion accidents at home and abroad, it is found that if an explosion hazard can be discovered in time and effective measures taken in the early stage, the explosion can be avoided or casualties can be reduced.

- Due to the long induction period of sulfur dust explosion, sulfur dust catches fire and spreads slowly, and will release a large amount of smoke and pungent sulfur dioxide gas. The early characteristics are obvious, and it is easier to find out by post-enhanced monitoring.

- After determining that the sulfur is on fire in a restricted space, it is necessary to avoid direct impact of water flow on the periphery of the fire surface or the outer wall of the air duct; when conditions permit, it is best to use steam to extinguish the fire; if the on-site personnel cannot judge the correct disposal measures, emergency avoidance measures should be taken. Evacuate to a safe area in a dangerous way (stop all operations on site).

- When a sulfur pile is on fire, it is necessary to avoid directly impacting the sulfur pile or the ground around the fire point with a direct water jet. Because the air flow brought by the water column impacting the sulfur pile or the ground will disturb the sulfur dust and suspend the sulfur dust in the air, reaching the explosion limit, causing an explosion. , To expand the accident hazards. The best way to extinguish fire is to use nozzles with good atomization effect, such as atomizing water cannons or blooming water cannons, to pour the fire area to extinguish the fire. A water curtain spray system can be used together to form a liquid mist screen of fire extinguishing agent and reduce the impact of sulfur Surface causes the possibility of dust and sulfur suspended in the air.

- Do a good job in the safety of rescuers, because sulfur fires will release a large amount of toxic gas sulfur dioxide, which is easy to cause personnel poisoning. When extinguishing a sulfur fire, you must wear fire-proof and heat-insulating clothing and air respirators to avoid thermal radiation damage and avoid direct inhalation of toxic gases.

- When liquid sulfur is in danger of fire in the liquid sulfur storage tank and the liquid sulfur pool, the steam fire extinguishing system should be quickly turned on and the gas-phase connecting pipe control valve should be closed.

Practice has found that the best way to extinguish a sulfur fire is water and steam, and dry powder fire extinguishers are not effective.

- Management measures to prevent sulfur fire and dust explosion

In the storage and transportation system, sulfur fire and sulfur powder explosion can be avoided. Preventive measures can be taken to avoid the burning and explosion of sulfur. Although control measures cannot completely prevent the occurrence of explosions, they can reduce losses as much as possible and control the consequences to an acceptable level.

- Strengthen daily management, find areas where ferrous sulfide and fine sulfur may accumulate, remove sulfur powder inside and outside the equipment, and reduce the risk of fire and explosion accidents caused by spontaneous combustion of ferrous sulfide and sulfur powder accumulation.

- Upgrade the materials of the key equipment of the storage and transportation system in contact with sulfur, and use materials that are not easy to chemically react with sulfur dust to avoid spontaneous combustion of ferrous sulfide.

- The early detection of sulfur burning is very important. While relying on the video monitoring system and the safety alarm system, the post personnel must strengthen the inspection of key parts of the site, and achieve early detection, early reporting, and early disposal of hidden dangers to control the accident in the budding state.

- Strengthen the maintenance and management of safety facilities, formulate a special management system, and regularly check the status of the silos and belt conveyors for spraying and dust suppression facilities. In the process of sulfur transportation, the system spray dust suppression facilities must be put into use; the silo dome spray facilities must be tried out once a week.

- Strengthen the operation and management of rotating equipment and regular lubrication to avoid the ignition of sulfur due to heat accumulation due to equipment friction.

- Strengthen the management of direct operations and improve the fire level of areas where fine sulfur is likely to accumulate. Feasible safety prevention and control measures must be formulated and implemented before a fire breaks out.

- Regularly carry out emergency drills for sulfur fire and dust explosion, and personnel should be trained in first aid and the use of gas defense equipment to improve the emergency response capabilities of employees.

Sulfur is a secondary flammable solid, and sulfur dust is easy to burn in the air or mixed with oxidant and even cause dust explosion. Therefore, both in the process of transportation and storage in the warehouse should be stored reasonably, and the equipment for storing sulfur should also be selected for products with a working temperature of less than 190°.

Shenzhen CESP Co., Ltd. focuses on the field of special industrial lighting. It is a high-tech enterprise integrating design, R&D, production and sales. A complete management team provides expertise in the lighting fields of domestic electric power, metallurgy, railways, large industrial and mining enterprises, and marine ships. It also provides advanced technical support and product supporting services for internationally renowned companies.

CES-J explosion proof led floodlight with ATEX\IECEX/UL certification, which can be used in wastewater treatment, oil refineries, drilling platforms, petrochemical facilities, catering facilities, tunnels, outdoor walls and anchors The general area lighting installed, as well as hazardous areas with flammable steam and gas, is an explosion-proof floodlight with high lumen and high luminous efficiency, designed to meet the requirements of applicable hazardous gas areas, and the working environment with a temperature as high as 40°C , Can also work in humid environment, IP rating is IP66.

The shell is made of a die-cast aluminum shell with a special process, and the powder coating is added to make the explosion-proof lamp have a high-strength hard shell and corrosion resistance. At the same time, the appearance is also excellent. The excellent three-dimensional heat dissipation structure design increases the lamp The efficiency and service life can withstand high mechanical strength and temperature changes. The lamp has a built-in ballast, no need to be equipped with a ballast box, and the lamp body and the ballast box are designed separately, with a compact structure to ensure the explosion-proof performance of the shell.

Although his lamp beads have different powers, the number of lamp beads is also different, but his luminous flux is maintained at 110-140lm/W, and the color temperature and installation angle can be adjusted between 3000-6500K according to customer needs. This lamp There are also lighting solutions in dusty environments. If you have any needs in this area, you can contact us for consultation, or if you have other lighting consultations, you can also contact us to provide you with lighting solutions.

Hazardous Location Linear Light LED CES-EX-LN-02P

How important is the division of explosion-proof areas?

Explosive substances: some flammable substances are produced in many production sites.

Explosive substances exist in about two-thirds of coal mine sites. In the chemical industry, explosive substances exist in more than 80% of the production workshop area.

Oxygen: oxygen in the air is everywhere.

Ignition source: a large number of electrical instruments are used in the production process. Various frictional electric sparks, mechanical abrasion sparks, static sparks, high temperature, etc. Are inevitable, especially when instrumentation and electrical failures occur.

From an objective point of view, many industrial sites meet the explosion conditions. When the mixed concentration of explosive substances and oxygen is within the explosive limit range, if there is an explosion source, an explosion will occur. Therefore, it is necessary to take explosion protection.

And this article focuses on the division of hazardous location in zone and division systems

Note: this article is published by the CESP technology center in conjunction with the global explosion-proof standard system. If you have any questions, please contact us.

Explosion is a form of combustion. When the speed of the oxidation reaction reaches a certain level, the reaction instantly releases a large amount of heat, causing the gas to expand violently, forming a shock wave, and accompanied by sound. This phenomenon is explosion gas. Explosion gas is the result of rapid combustion. According to the explosion triangle principle: explosive substances, oxygen, and ignition sources, measures to eliminate electric sparks and dangerous high temperatures in electrical equipment including automation instruments will help prevent combustion and avoid the formation of explosions.

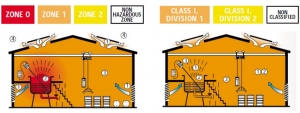

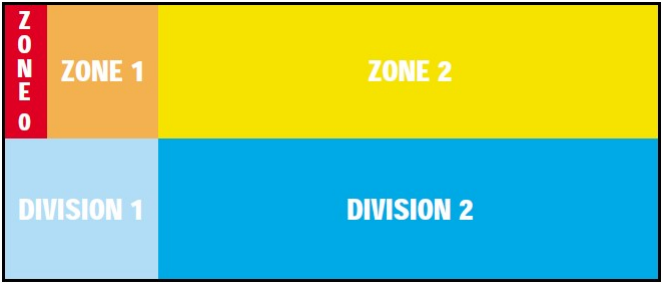

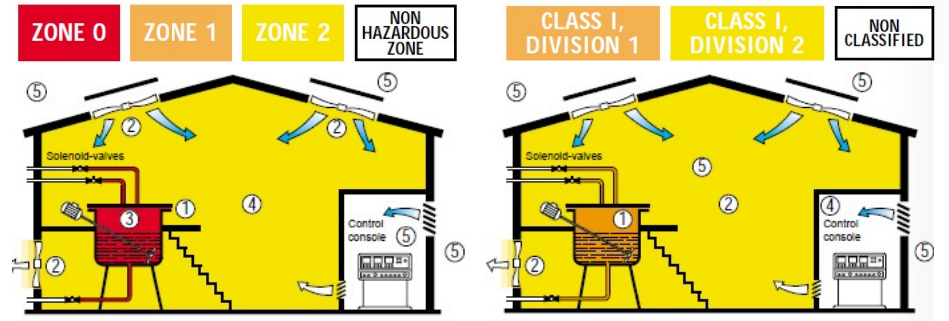

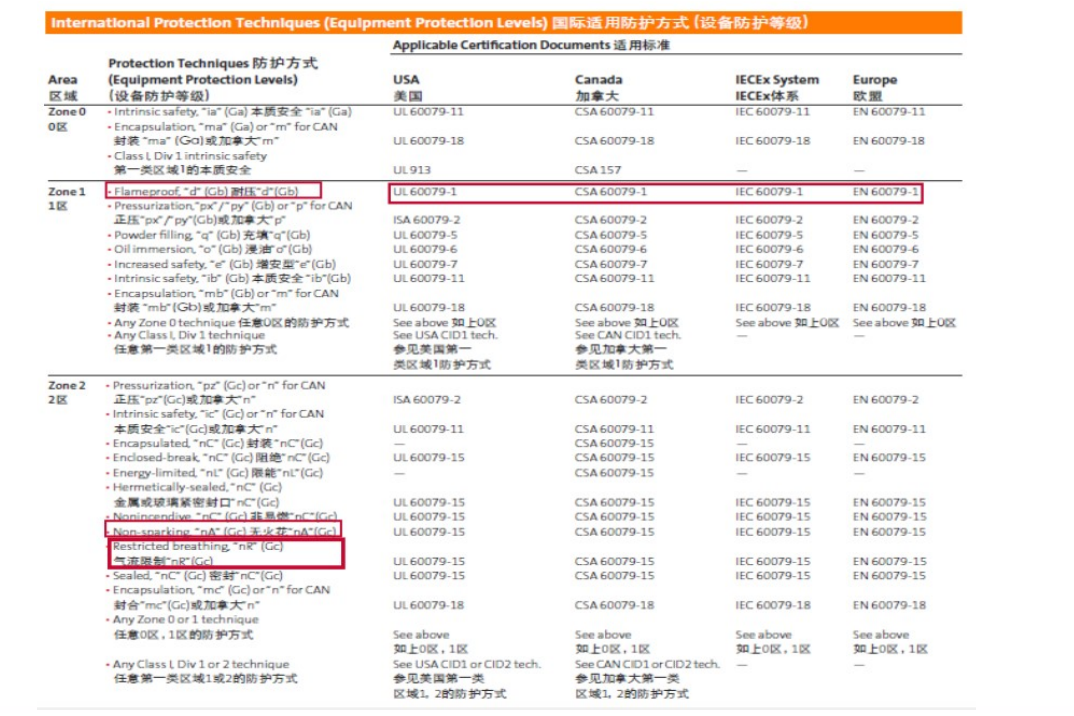

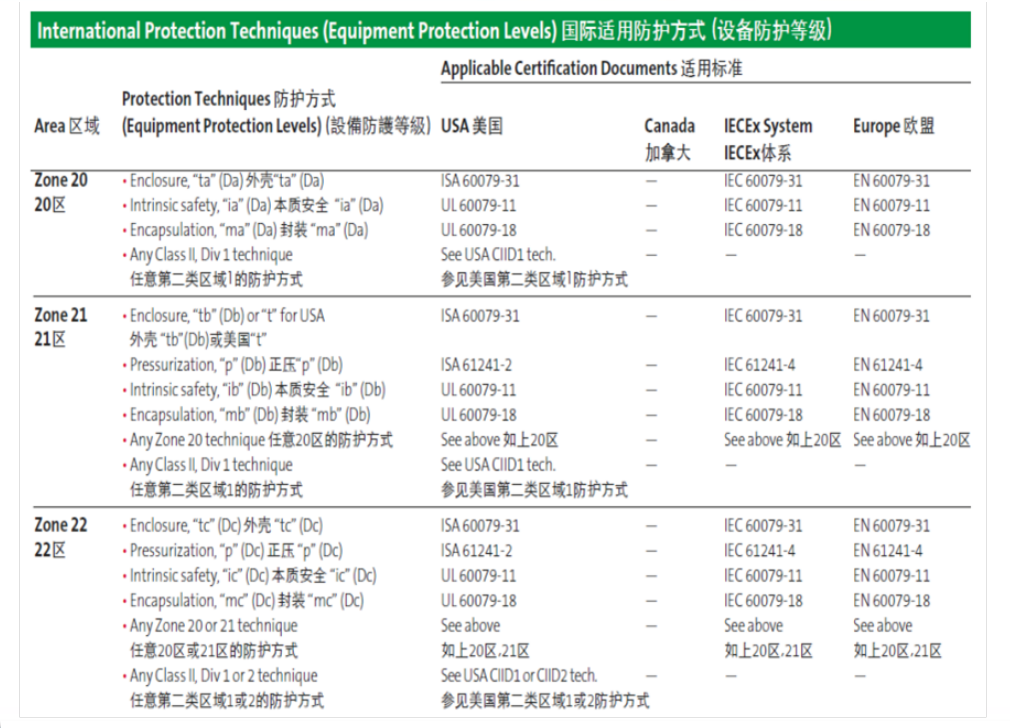

Therefore, hazardous locations are divided into different areas according to the frequency and duration of the explosive environment, and the equipment requires different explosion-proof levels. According to the different degree of danger (continuous danger/intermittent danger/danger under abnormal conditions), the division is the level of the dangerous zone coming out (zone 0/ 1/ 2; zone 20/21 /22; division 1 /2).

|

Area type |

Division system |

Zone system |

Definition |

Time definition |

|

Persistent danger |

Division 1 |

Zone0 / zone20 |

Places where explosive environment persists or exists for a long time |

Above 1000H/y |

|

Intermittent danger |

Division 1 |

Zone1 / zone21 |

Under normal circumstances, there may be places with explosive atmospheres |

1000H/y-10H/y |

|

Dangerous under abnormal conditions |

Division 2 |

Zone2 / zone22 |

Under normal circumstances, it is impossible to have an explosive environment, or even if it exists, it is a short-term place |

10H/y or less |

Note: 1H/y is regarded as a non-hazardous location.

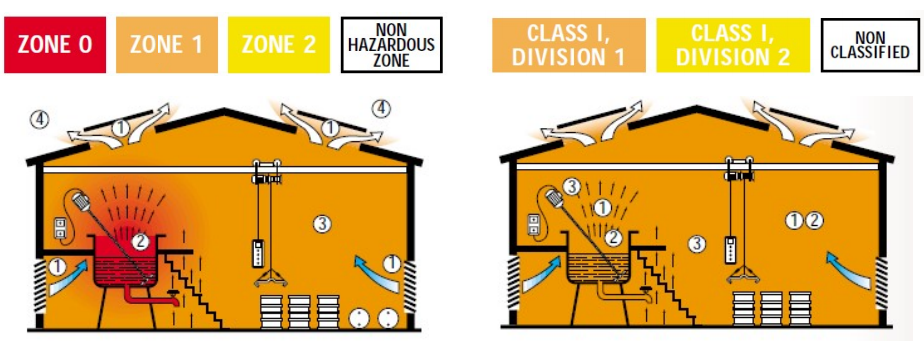

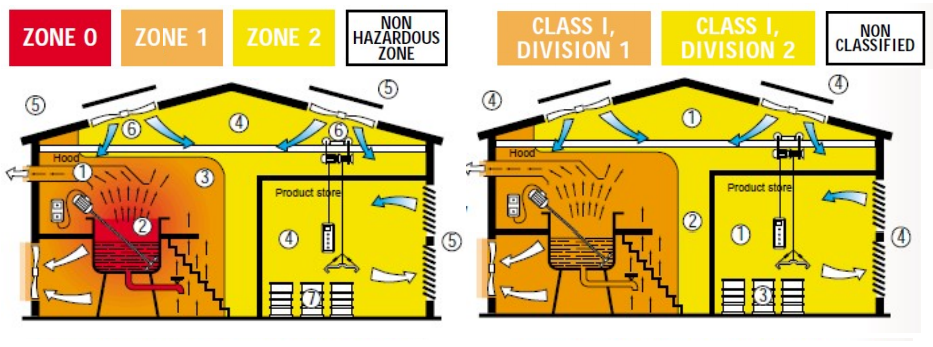

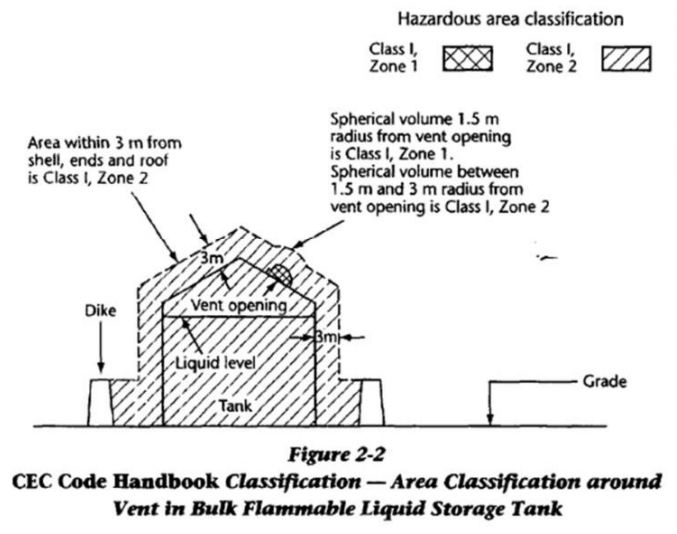

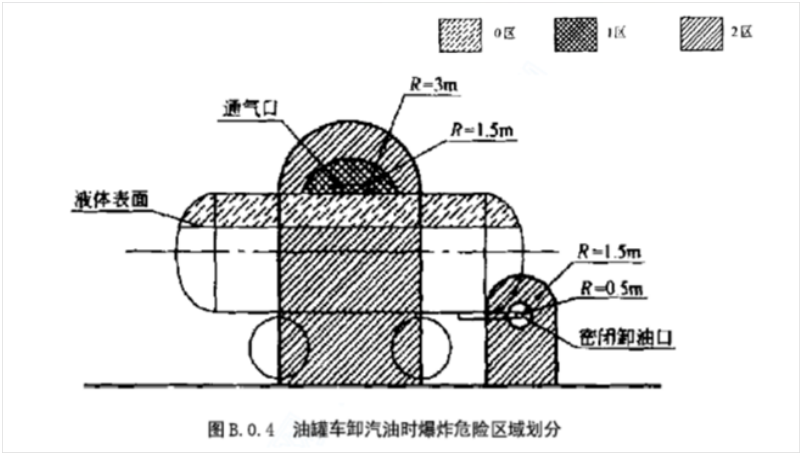

- The following are some examples of hazardous location divisions, for reference

- 1、Natural ventilation;

- 1、Division 1 Area;2、Division 2 Area;

- 2、Zone 0 area;

- 2、division 1 area

- 3、Zone 1 area;

- 3、electrical equipment must comply with division 1 nec/cec technical requirements and installation requirements;

- 4、Non-explosion-proof area;

- 1、Cover The Reaction Tank 5、 Non-Explosion-Proof Area;

- 1、Division 2 Area;

- 2、Zone 0 Area;6、Mechanical Ventilation;

- 2、Transition Area Between Division 1 And Division 2

- 3、Zone 1 Area; 7、Products And Work Area

- 3、Products Are Stored In Division 1;

- 4、Zone 2 Zone; Separate Domains;

- 4、Non-Explosion-Proof Zone

- 1、The Reaction Tank Is Completely Enclosed

- 1、Division 1 Area;2、Division 2 Area;

- 2、Mechanical Ventilation;

- 4、The control room of the ventilation/pressurization equipment

- 3、Zone 0 Area;

- is isolated as a non-hazardous area

- 4、Zone 2 Area;

- 5、Electrical Equipment Must Meet The Technical Requirements And

- 5、Non-Explosion-Proof Area

- Installation Requirements Of Division 2 In NEC/CEC;

Tanker truck division of explosion hazardous location when unloading gasoline

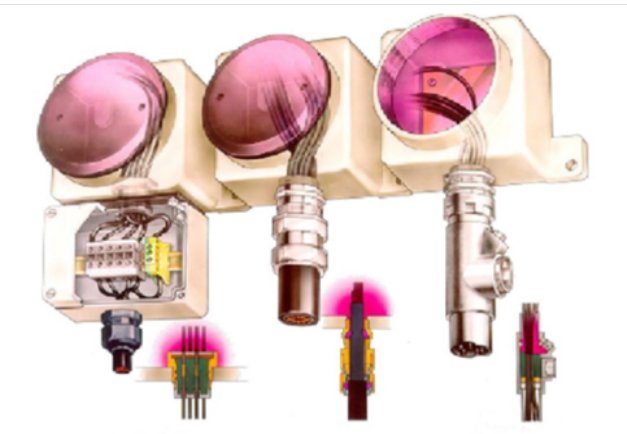

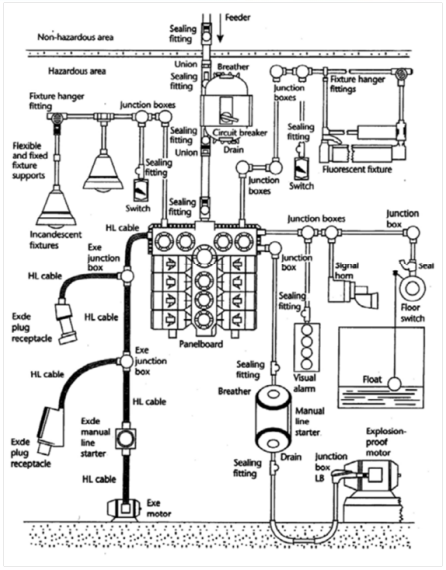

North American explosion-proof electrical installation

Canada: Canadian electrical code

US : national electrical code –NFPA 70

Installation method:

Conductors in rigid conduit

Conduit connection

Non armored cable

Non-Armoured cable

Armored cable

Armored cable

Ex d +ex e junction box cable entry pipeline entry

(ex e gland seal) +ex d gland seal +sealing device

In order to ensure the safety of personnel and the normal operation of production, explosion-proof electrical equipment should be selected in strict accordance with corresponding standards in hazardous locations. Only reasonable selection, correct installation and necessary maintenance can ensure production safety.

Explosion-proof mark explanation

This article mainly explains the global explosion-proof mark and explosion type, including the North American division system explosion-proof mark, Europe and the international zone system explosion-proof mark, it is not only suitable for explosion-proof lamps, but also for other explosion-proof equipment products.

Note: This article is authoritatively published by CESP Explosion-proof Technology Center, for reference only, if you have any contact, please contact us.

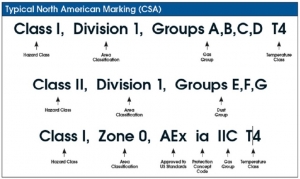

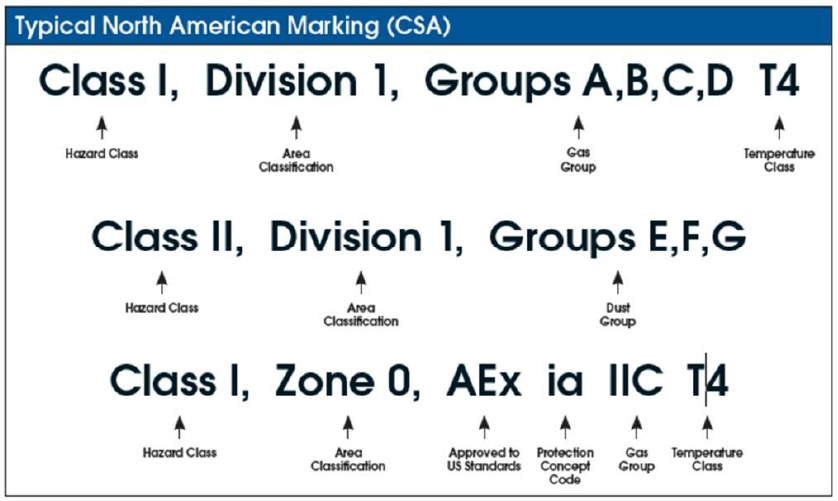

Typical North American Marking (CSA)

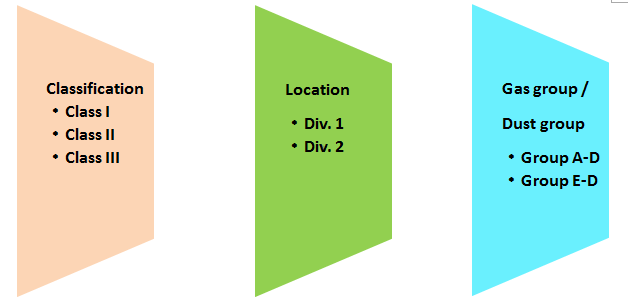

Definition of Hazardous Locations - North America

Classification of Regional Explosive classification

|

Class I ·Flammable gas, vaporization or liquid substance Class II ·Combustible dust |

Class I Division/Zone Area

Explosive gas application Location comparison table

|

Division 1 Flammable or explosive substances in a normal environment, or the presence of recurrent |

Zone 0 Flammable or explosive substances in a normal environment for a long time or continuous presence Zone 1 Flammable or explosive substances may be present in a normal environment |

|

Division 2 Flammable or explosive substances are extremely unlikely to exist in a normal environment |

Zone 2 Flammable or explosive substances are extremely unlikely to exist in a normal environment |

Class I Division/Zone

Explosive gas group classification table

|

Division 1 and 2 |

Zone 0, 1 and 2 |

|

A (acetylene) |

IIC (acetylene & hydrogen) |

|

B (Hydrogen) |

|

|

C (Ethylene) |

IIB (Ethylene) |

|

D (propane) |

IIA (propane) |

Class I Division/Zone

Explosive dust group classification table

|

Division 1 and 2 |

Zone 20, 21 and 22 |

|

Metal dust |

IIC (Carbonaceous dust) |

|

F (Carbonaceous dust) |

IIB (Non-conductive dust) |

|

G (Non-conductive dust) |

IIB (Non-conductive dust) |

|

IIA (combustible flyings) |

|

Division |

||

|

Class I Explosive gas |

Group D |

Gas (coal mine) |

|

Group D |

Propane |

|

|

Group C |

Ethylene |

|

|

Group B |

Hydrogen |

|

|

Group A |

Acetylene |

|

|

Class II Explosive dust |

Group E |

Metal Dust |

|

Group F |

Black charcoal /Coal/Coke Dust |

|

|

Group G |

Grain dust |

|

|

Class III flyings |

||

Division System (Class II & Class III Dust)

|

Explosion-proof type |

Mark |

Location |

|

Dust Ignition Proof Dust Protected Pressurisation Pressurisation Intrinsic Safety |

DIP NI PX PY PZ IS |

Class II Division 1 Division 2 Division 1 Division 2 Division 1 |

|

Fiber & Flying Protection |

- |

Class III Division 1 & 2 |

|

International - Zone |

|

|

Group I - Coal mine gas environment |

|

|

Group II Explosive atmospheres other than coal mines |

IIA Propane |

|

IIB Thylene |

|

|

IIC Hydrogen + Acetylene |

|

|

Group III Explosive dust environment other than coal mines |

IIIC Conductive dust |

|

IIIB Non-conductive dust |

|

|

IIIA Flammable flyings |

|

|

North American Zone system |

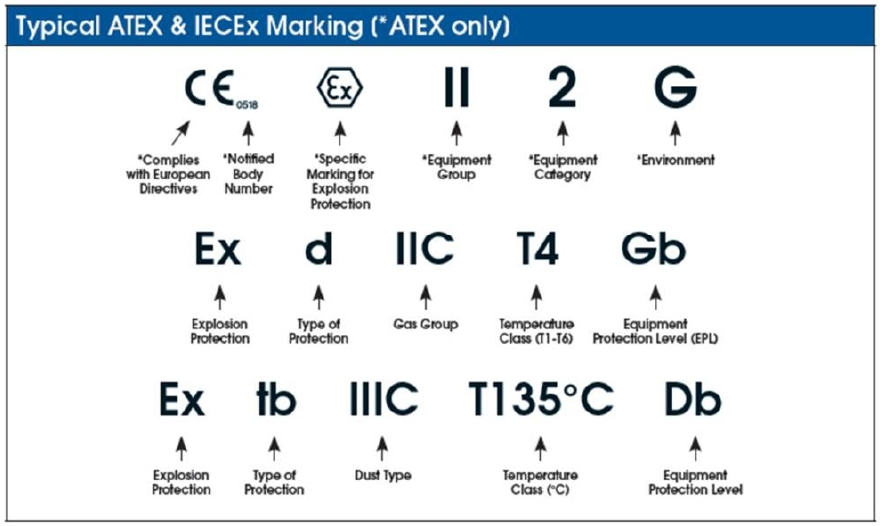

ATEX |

IECEx |

ATEX |

Operating conditions |

|

Ma |

Ma |

Ma |

M1 |

The device still operates when an explosive environment occurs |

|

Mb |

Mb |

Mb |

M2 |

When an explosive environment is present, the device is powered off |

|

Ga |

Ga |

Ga |

1G |

Still running in Zone 0/1/2 |

|

Gb |

Gb |

Gb |

2G |

Still running in Zone 1/2 |

|

Gc |

Gc |

Gc |

3G |

Still running in Zone 2 |

|

Da |

Da |

Da |

1D |

Still running in Zone 0/1/2 |

|

Db |

Db |

Db |

2D |

Still running in Zone 21/22 |

|

Dc |

Dc |

Dc |

3D |

Still running in Zone 22 |

Note: the North American Division system does not have the concept of EPL equipment protection level

Zone System(Gas)

|

Explosion-proof Type |

Mark |

Equipment Protection Level |

|

Intrinsic safety ”i” Encapsulation ”m” |

Ex ia Ex ma |

Ga Ma Ga Ma |

|

Flame Enclosure ”d” Intrinsic safety ”i” Increase safety ”e” Pressurized ”p” Oil immersion ”o” Encapsulation ”m” Power Filling ”q” |

Ex d Ex ib Ex e Ex px Ex py Ex o Ex mb Ex q |

Gb Mb Gb Mb Gb Mb Gb Mb Gb Mb Gb Mb Gb Mb |

|

Intrinsic safety ”i” ”n” Type Encapsulation ”m” |

Ex ic Ex nL Ex nA ExnC Ex nR Ex mc |

Gc Gc Gc |

Zone System(Dust)

|

Explosion-proof Type |

Mark |

Equipment Protection Level |

|

Dust Ignition Protection by Enclosure ”ta” Intrinsic safety ”i” Encapsulation ”m” |

Ex ta Ex ia Ex ma |

Da Da Da |

|

Flameproof Enclosure ”tb” Intrinsic safety ”i” Pressurized Enclosure ”p” Encapsulation ”m” |

Ex tb Ex ib Ex p Ex mb |

Db Db Db Db |

|

Dust Ignition Protection by Enclosure ”tc” Intrinsic Safety ”i” Encapsulation ”m” |

Ex tc Ex ic Ex mc |

Dc Dc Dc |

|

Zone System Group II |

Division System Class I |

Maximum surface temperature / ⁰C |

|

T1 |

T1 |

450 |

|

T2 |

T2 |

300 |

|

T2A |

280 |

|

|

T2B |

260 |

|

|

T2C |

230 |

|

|

T2D |

215 |

|

|

T3 |

T3 |

200 |

|

T3A |

180 |

|

|

T3B |

165 |

|

|

T3C |

160 |

|

|

T4 |

T4 |

135 |

|

T4A |

120 |

|

|

T5 |

T5 |

100 |

|

T6 |

T6 |

85 |

Note: The Max. surface temperature of Zone Group I is 150⁰C or 450⁰C.

Global Explosion-Proof Standard Introduction

Product standards are usually based on international, regional, national, industry, and enterprise. This article focuses on introducing national and alliance standards of explosion proof luminaires.

Note: This article is published by the CESP Technology Center in conjunction with the global explosion-proof standard system. If you have any questions, please contact us.

National standards:

- China GB

- German DIN

- Canada CAN

- British BS

Regional standards:

- European Community Standard (CEN)

- European Committee for Electrotechnical Standardization (CENELEC)

International level standards:

- International Organization for Standardization (ISO)

- International Electrotechnical Commission (IEC)

The standards usually implemented by our explosion-proof lamps include:

- Chinese national standard GB

- S. nationally recognized UL

- Canadian National Standard CSA

- EN recognized within the European Union

- IEC issued by the National Electrotechnical Commission

According to the different explosion-proof systems, the global explosion-proof luminaires are also divided into two categories: Zone system standards and Division system standards. Among them, the parent standard of the Zone system is the IEC 60079 series of standards, and other standards are equivalent, modified, and directly quoted based on it as the parent standard.

Zone system:

- China-GB 3836 series

- International -IEC 60079 series

- Europe-EN 60079 series

- Canada-CSA 60079 series

- United States-UL 60079 series, ISA 60079 series

- GB 12476 series (dust)

- IEC 61241 series (dust)

Division System:

- UL 1203

- UL 913

- ISA 12.12.01

- NFliA 496

- FM3615

- FM3610

- FM3611

- FM3616 etc.

- Exlilosion-liroof standards for sliecific liroducts

American

- CSA 30

- CSA 157

- NFliA 496

- CSA 213

- CSA 25 etc.

- Exlilosion-liroof standards for sliecific liroduct

Canada

Explosion-proof standards of UL involving specific products:

- UL 783-Electric Flashlights and Lanterns for Use in Hazardous (Classified) Locations

- UL 844-Standard for Safety Luminaires for Use in Hazardous (Classified) Locations

- UL 674-Standard for Safety Electric Motors and Generators for Use in Hazardous (Classified) Locations

- UL 2225-Standard for Safety Cables and Cable-Fittings For Use In Hazardous (Classified) Locations

- UL 823-Electric Heaters For Use In Hazardous (Classified) Locations

- UL 121203-Portable Electronic Products Suitable for Use in Class I and II, Division 2, Class I, Zone 2 and Class III, Division 1 and 2 Hazardous (Classified) Locations

- UL 894-Switches for Use in Hazardous (Classified) Locations ( UL1203 replaced)

- UL 1207-Sewage Pumps for Use in Hazardous (Classified) Locations (replaced by UL674)

CSA related to the explosion-proof standards of specific products

- 2 No. 137-M1981 (R2014), Electric luminaires for use in hazardous locations

- 2 No. 145-11, Electric motors and generators for use in hazardous (classified) locations

- 2 No. 159-M1987 (R2014), Attachment plugs, receptacles, and similar wiring devices for use in hazardous locations: Class I, Groups A, B, C, and D;

- Class II, Group G, in coal or coke dust, and in gaseous Mines

- 2 No. 174-M1984 (R2012), Cables and cable glands for use in hazardous locations

The following regulation are from North American authoritative explosion-proof structures for your reference.

The following regulation are from International and European authoritative explosion-proof structures for your reference.

ATEX & IECEx

- IEC/EN 60079-0

- IEC/EN 60079-1

- IEC/EN 60079-2

- IEC/EN 60079-5

- IEC/EN 60079-6

- IEC/EN 60079-7

- IEC/EN 60079-11

- IEC/EN 60079-15

- IEC/EN 60079-18

- IEC/EN 60079-28

- IEC/EN 6007931

Standard

- General Requirement

- Flameproof Enclosure

- Pressurized Enclosure

- Power Filling

- Oil lmmersion

- Increased Safety

- Intrinsic Safety

- Type of Protection

- Encapsulation

- Transmission Systems Using Optical Radiation

- Dust Ignition Protection by Enclosure

Protection Technique

- --

- “d”

- "p"

- "q"

- "o"

- "e"

- "i"

- "n"

- "m"

- --

- "t"

Protection Technique

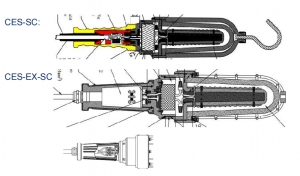

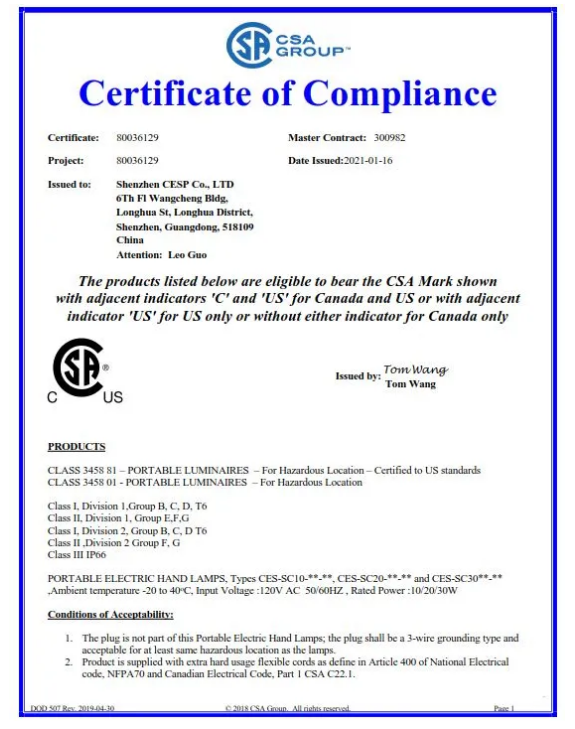

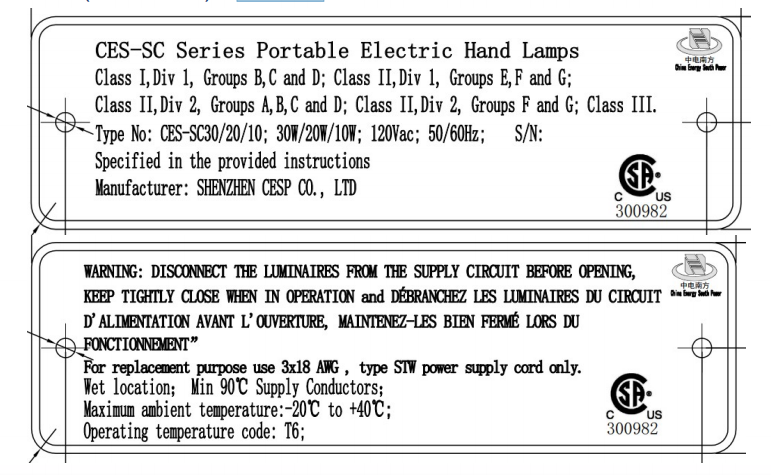

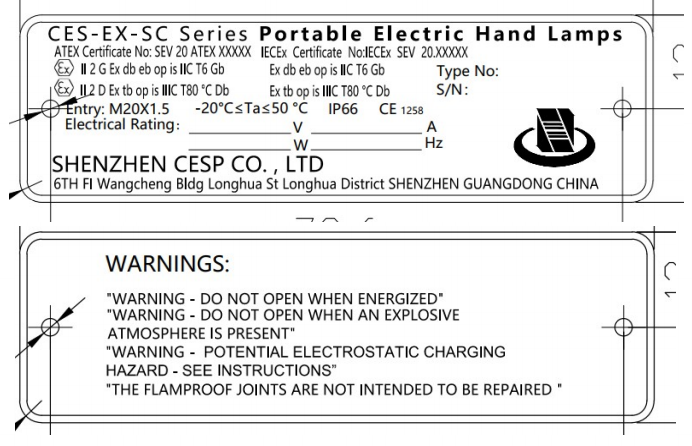

What's the advantage of CES-SC Explosion proof LED Hand Lamp?

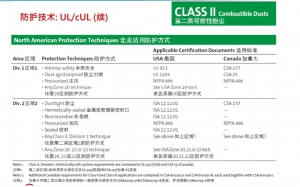

CESP explosion-proof LED portable hand lamp was designed in 2019. After continuous modification and testing, it got European ATEX and IECEx Certtificate Zone 1 Zone 21 in 2020. It also have obtained Class 1 Division 1 & 2 Explosion-proof certified (CSA 137 and UL 844 Standard) by CSA Group in January 2021.

As the first explosion-proof system standard of North American Class 1 Division 1 flameproof LED explosion-proof hand lamp in the world, CSA Group Kunshan Laboratory held a certificate ceremony on January 27, 2021, it means a major breakthrough of CESP in the global explosion-proof field .

1. Introduce of CES Explosion proof LED Hand Lamp

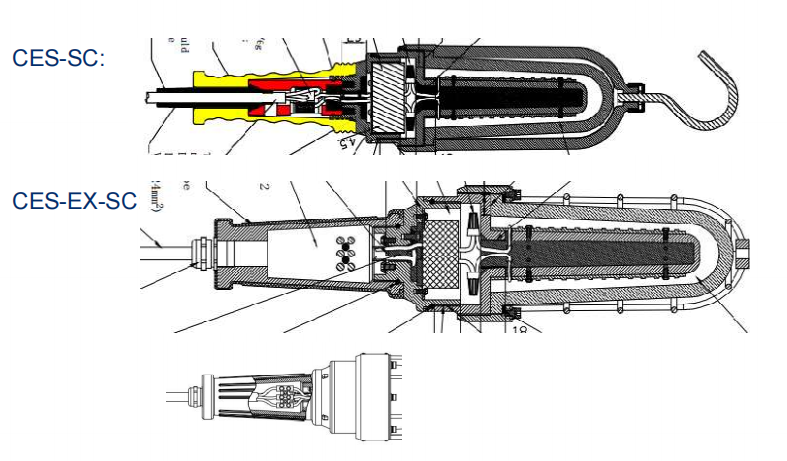

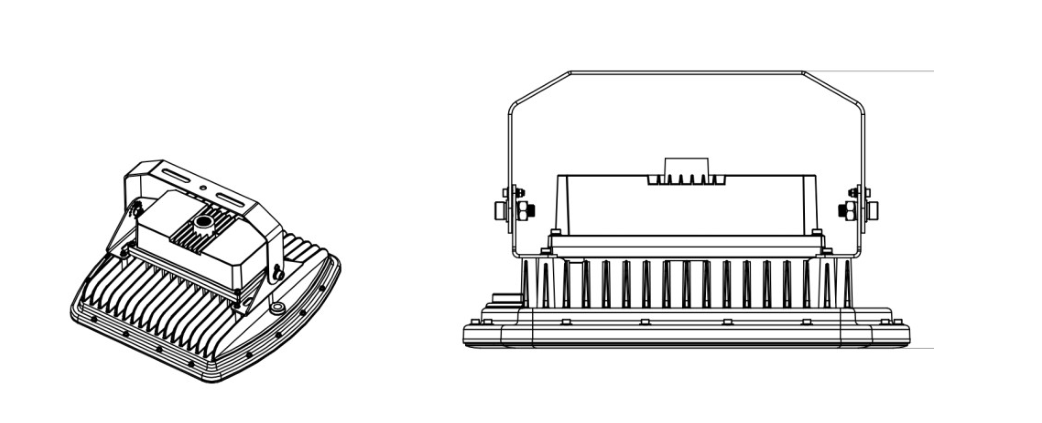

Structural design: The lamp body of the SC series explosion proof LED hand lamp is made of high-strength VO grade rubber handle and ADC12 aluminum alloy and equipped with low-carbon steel wire, which helps to reduce weight and improve durability.

Material: The housing is made of high-strength tempered glass (10mm), which has been tested by internal pressure and hydraulic pressure. The anti-corrosion grade is WF2, IP grade is up to IP67, and it can withstand 7J pressure.

Optical design: use high-quality LM80 certified LED chips, with a luminous efficiency of up to 130LM/W. For example, 30W explosion proof handlamp can reach to 3900 lumen flux, and with a 180° or 360° beam angle to meet all-round lighting.

In general, CES-SC explosion proof safety hand lamp is beautiful and simple in appearance, and convenient to operate, can be hand-held, placed on a table, magnetically attracted, and suspended for lighting. As the explosion proof hand lamp is very light and small, it can provide portable lighting for hazardous locations and temporary projects. It is very suitable for close work and inspection activities in hazardous areas where require explosion protection, such as quick plant turnarounds, MRO projects, oil fields, marine sites and tank cleaning etc.

Schematic

2. Key benefit: Compare with existing explosion-proof hand lamps or traditional portable explosion proof lamp on the market.

List.1 - At present, there are very few explosion-proof led hand lamps that can meet the requirements of class 1 division 1 in the market. The traditional explosion proof hand lights are mostly with bulb. CESP-SC series explosion proof led hand light conform to Class 1 Division 1, Class II Division 1, Class 1 Division 2, Class II Division 2, Class III, and uses high lumen LED chips, that’s a safe and efficient explosion-proof lighting fixture.

List.2 - Most of the explosion proof portable lamp are low-power or increased safety on the market, but CESP explosion-proof hand lamps are designed to be flameproof type, which is nore sfety and reliale.