The port is an important transportation hub and a window to realize an export-oriented economy. China’s major ports have occupied an important position among the world’s ports. The container throughput has been ranked first in the world for many years, becoming the world’s largest port and container throughput. , The fastest growing country. As the economy continues to grow, energy conservation, emission reduction, and efficiency improvement have become urgent requirements for China and the world. For example, the power consumption of lighting in the Shanghai International Port Area is as high as 5.94 million KWh. Port companies have always been large energy consumers in the transportation industry. Energy saving has become one of the important means for port companies to enhance their international competitiveness in the new era. Therefore, the solution to port lighting Is the top priority.

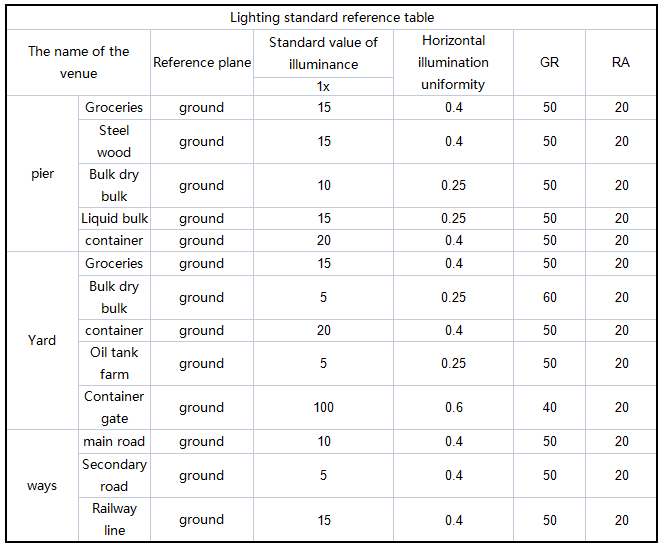

- Lighting standards

The dock lighting standards for different purposes will be different. The following only gives the lighting standards for general areas.

The wharf is located along the river and the ocean, and the air humidity is relatively high, and the erosion of salt fog and oceanic climate is serious. In addition, port refineries, also known as seaside oil refineries, are usually flammable and explosive, but because they are close to the sea, corrosion prevention needs to be considered. Especially near the southeast coastal areas of China, there are more typhoons and heavy rains, and the climatic conditions are harsh. At the same time, in the docks that transport bulk goods (coal or grain), there is the diffusion of fine particles, which will cause serious dust pollution. These are all factors that need to be considered when designing lighting. The lamps and lanterns used in the dock should meet the following requirements:

- High power: Because the height of the gantry crane is about tens of meters, it has the characteristics of wide adaptability and large working range. In order to meet the illumination requirements of the working surface, the power of general fluorescent lamps should be above 400W, and the power of LED lamps should be Above

- Long life: Due to the high height of the gantry crane, it is not easy to repair the lamp after it is damaged, so it is necessary to install a lamp with a long service life.

- Safe and reliable: There are many types of goods on the port terminal and the environment is complicated. It is necessary to configure safe and reliable lighting fixtures to ensure the lighting safety of the port terminal and prevent fire incidents caused by the short circuit of the lamps.

- High protection level: The port is in a humid environment all the year round, so the requirements for the waterproof and dustproof level of the lamps are relatively high. The lamps with high protection level can prevent water vapor from entering the lamp body and prolong the service life of the lamps. The lamp shell is made of high-quality aluminum alloy die-casting, and the outer surface is treated with high-voltage electrostatic spray, which improves the overall anti-corrosion level of the product. The whole lamp has an independent heat dissipation system and the drive is external. Waterproof, so that the protection level of the lamp reaches IP65, without fear of the humid environment of the port terminal. The anti-corrosion level of lamps needs to reach the WF2

- The light source and accessories are easy to replace.

- Lamp parts have good anti-corrosion performance.

- The lamp is installed stably and has good wind resistance.

- Unless otherwise specified by the owner unit, lamps must comply with the latest national standards (GB), International Electrotechnical Commission (IEC) standards and International System of Units (SI) standards.

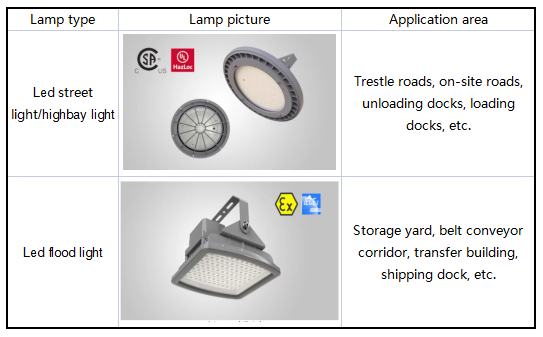

- Selection of lamps

- Simulation lighting

In the simulation, the coal operation terminal is taken as an example, and the simulation is carried out in various scenarios. The simulation results are as follows:

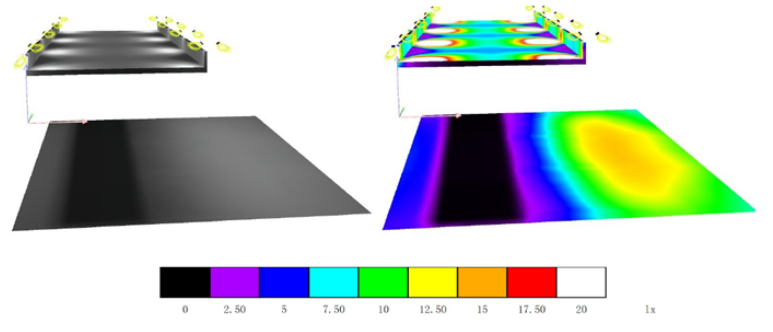

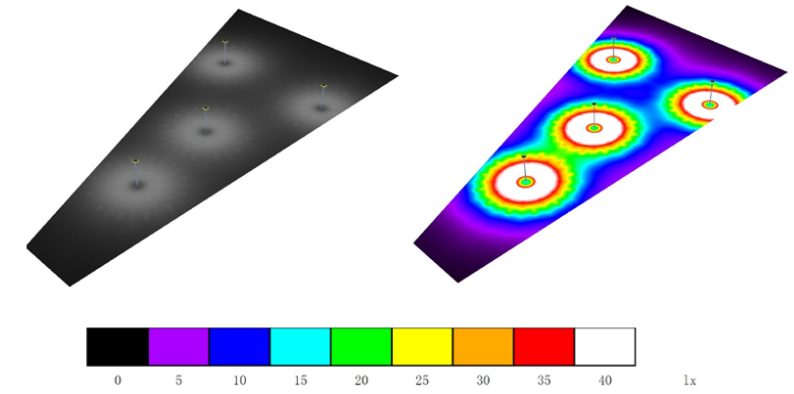

- Ship unloading dock

The unloading dock should not only illuminate the belt conveyor belt above, but also illuminate the side road. The lamps are installed on the brackets outside the conveyor corridor.

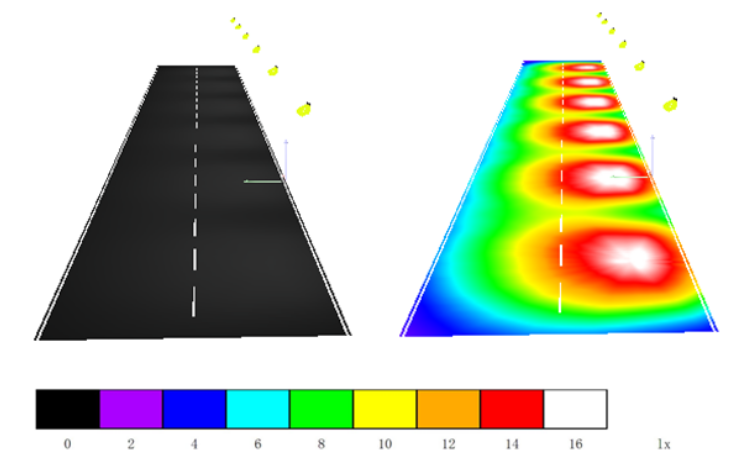

3D renderings and pseudo-color images

Calculation results

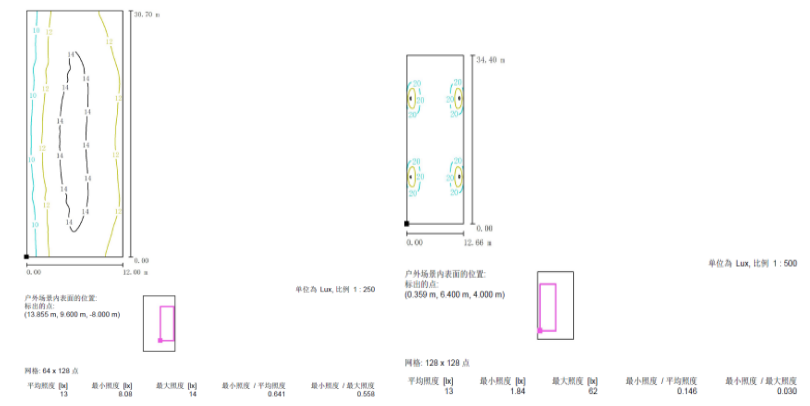

- Trestle

The trestle bridge is mainly for road lighting, so street lights can be used.

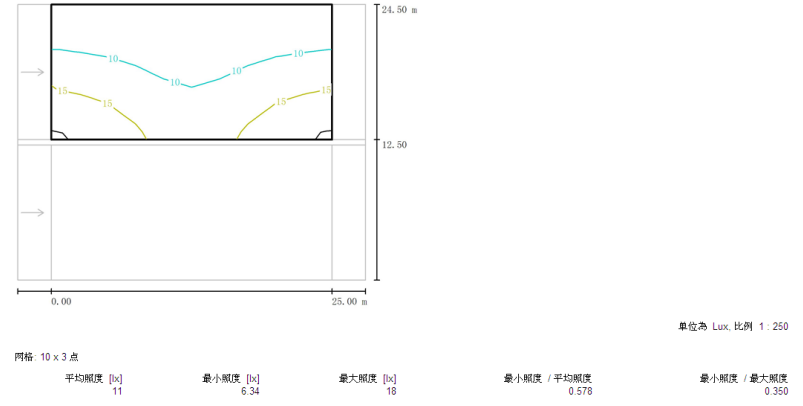

3D renderings and pseudo-color images

Calculation results

- Transfer building

Because of the power limitation of the belt conveyor, the belt length is limited, or the direction of the belt conveyor needs to be changed, the transfer building needs to be transferred. Because the transfer building is operated by humans, the illuminance requirements are high, and it needs to reach more than 100lx.

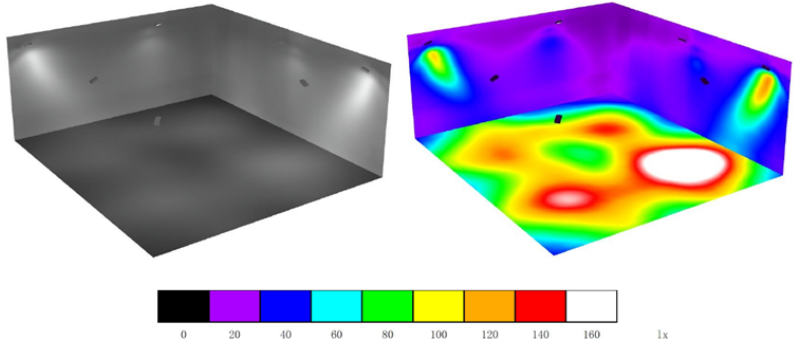

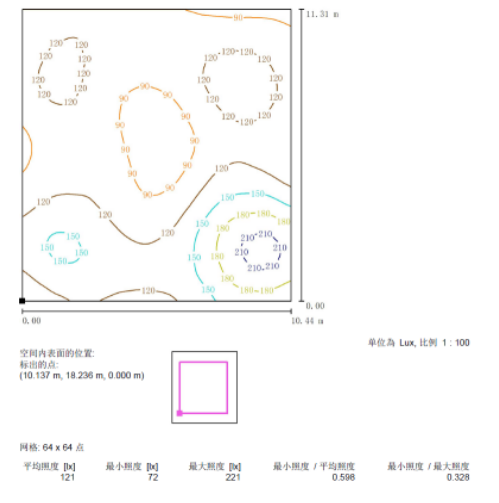

3D renderings and pseudo-color images

Calculation results

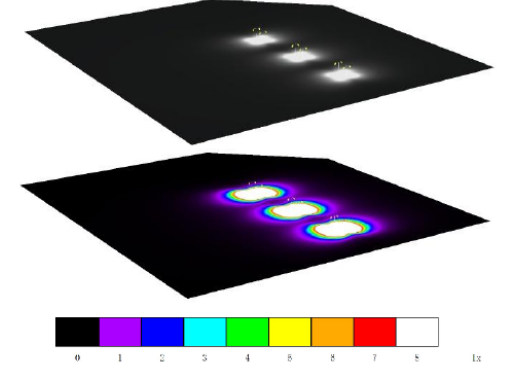

- Yard

The storage yard is generally a storage area for items, and the common lighting method is high-pole lighting.

3D renderings and pseudo-color images

Calculation results

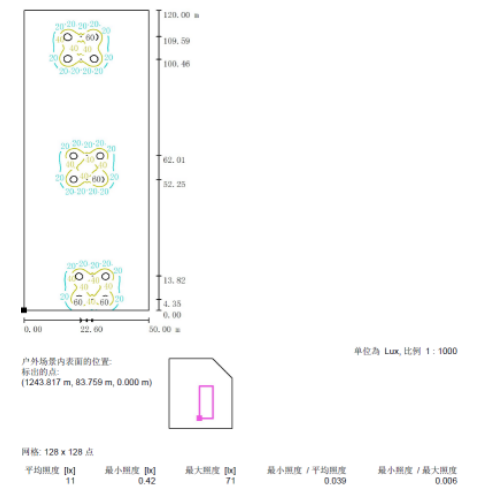

- Loading dock

Ship loading docks generally illuminate the ship’s deck and navigation channels in inland river basins. Street lights or floodlights can be used.

3D renderings and pseudo-color images

Calculation results

- Pictures of the scene

Loading dock

Unloading dock

Shenzhen CESP Co., Ltd. focuses on the field of special industrial lighting. It is a high-tech enterprise integrating design, R&D, production and sales. The complete management team covers the lighting fields of China's electric power, metallurgy, oil refining, railways, large industrial and mining enterprises, marine ships, etc. Provide professional lighting supporting solutions, and also provide advanced technical support and product supporting services for internationally renowned companies. CESP’s products have obtained North American UL certification, EU ATEX certification and international IECEX certification, which are very suitable for general area lighting installed in wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor or indoor installations. And use in places where flammable vapors, gases, combustible dust, fibers, or hazardous areas exist in flight.

The CES-EX-GB02 series explosion-proof high bay lamp body has a protection level of IP66 and an anti-corrosion level up to WF2. It is equipped with a corrosion-resistant high-strength aluminum alloy shell, which has good durability, vibration resistance, impact resistance and marine corrosion resistance.It is very suitable for salt water and corrosive environments. Although this explosion-proof lamp is a high-power LED high bay lamp, the power supply adopts wide voltage processing, can work under 100-277 VAC, 50/60Hz, and realizes constant current output. It has short-circuit and over-voltage protection functions, which greatly extend the lamp Service life. The explosion-proof LED high bay light shell is specially designed for heat dissipation, thereby improving the efficiency and service life of the LED lamp. The tempered glass cover is anti-glare design, with high illumination uniformity, no ghosting, effectively avoiding glare, spot and aperture, and does not damage the light efficiency . It is suitable for various low ceilings, platforms, high ceilings, high sheds and other places as solid lighting.

The CES-EX-J series of explosion-proof floodlights adopt a sealed structure with high waterproof and anti-corrosion performance. They comply with UL1598A marine certification and are very suitable for salt water and corrosive environments. Precise light distribution design and good optical system, coupled with excellent 3D heat dissipation structure design, make this high-power hazardous area floodlight, compared with traditional explosion-proof lighting fixtures, have the best lighting level and the lowest maintenance cost . As an increased-safety and shell-protected explosion-proof lamp, it can be used under T4 ambient temperature, and the shell is made of die-cast aluminum. The designer took into account the heat dissipation performance of the explosion-proof lamp, and designed the back of the lamp with a corrugated effect. It can work under the environment of -40℃-55℃, with longer life span, which can reach more than 50,000 hours. Obtained UL844/ATEX/IECEX certification, and guaranteed a five-year warranty, this makes this hazardous area floodlight very suitable for local lighting, low-level lighting, stairwells, gantry and walkways, craft skids, cable tray areas, low-overhead ocean void spaces, paint and solvent storage rooms, gas stations, offshore oil and gas platforms , Chemical industry and other hazardous environments.

CESP also has lighting solutions for offshore drilling and oilfield joint stations. If you have related lighting needs, you can contact us directly or call our hotline. We will provide quality services and lighting solutions that meet your needs.