Cement plants often have areas where explosive or flammable materials are present, such as coal dust, petroleum coke, or other volatile substances used in the cement-making process. In such areas, it is essential to use explosion-proof lighting fixtures to prevent accidents caused by sparks or overheating from standard lighting sources.

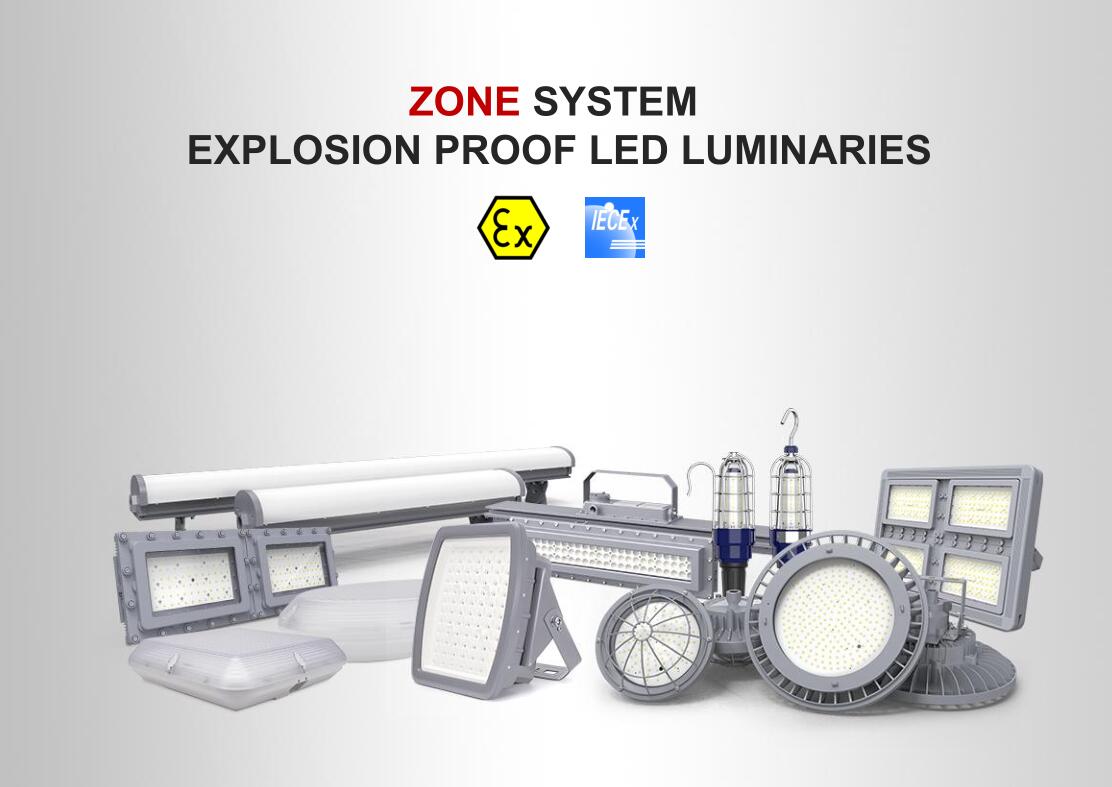

Explosion-proof lamps are specially designed to withstand and contain any internal explosion, preventing it from igniting the surrounding flammable substances. They are built with materials that can withstand high temperatures, corrosion, and impact, and are sealed to prevent dust and other debris from entering and igniting.

By using explosion-proof lighting fixtures in cement plants, the risk of fire or explosion is significantly reduced, providing a safer working environment for employees and preventing damage to equipment and infrastructure. Additionally, the use of explosion-proof lamps is often required by law or safety regulations to ensure compliance with safety standards and prevent accidents.

One of the areas in a cement plant that requires proper lighting is the preheater tower. This tower is used to preheat the raw meal before it enters the kiln. The temperature inside the tower can exceed 1,000°C, and dust and debris are constantly present. It is essential to have a lighting system that can withstand these conditions and provide clear and bright illumination.

To address the challenges of the preheater tower lighting environment, it is recommended to use explosion-proof lights. CESP's explosion-proof lights are an excellent solution for this application. They are designed to operate in hazardous environments and can withstand extreme temperatures and harsh conditions.

CESP's explosion-proof lights use LED technology, which is up to 80% more efficient than traditional lighting sources. This means that they can help to reduce energy consumption and lower operating costs for the cement plant. They also have a long lifespan, which reduces maintenance and replacement costs.

Another area in the cement plant that requires proper lighting is the grinding area. The grinding area is where the clinker is ground into cement. This area can be dark and dusty, making it challenging to see and work safely. To address this issue, it is recommended to use high bay LED lights. CESP's high bay LED lights are an excellent solution for this application. They provide bright and clear illumination, and their energy efficiency can help to reduce energy consumption and operating costs for the cement plant.

In conclusion, the lighting environment in a cement plant can be challenging due to the harsh conditions. To address these challenges, it is recommended to use explosion-proof lights in the preheater tower and high bay LED lights in the grinding area. CESP's explosion-proof lights and high bay LED lights are excellent solutions for these applications, providing clear and bright illumination while also helping to reduce energy consumption and operating costs.

Advice on lighting lux for cement plants

The required lux level for lighting in a cement plant depends on the specific area and task being performed. Generally, higher lux levels are needed in areas where precise tasks are being carried out, such as inspection and maintenance, while lower levels may be sufficient in areas where general visibility is needed.

For example, in the preheater tower where workers are carrying out tasks such as inspecting equipment or conducting maintenance, a lux level of at least 500 lux is recommended. In the grinding area, where workers are grinding the clinker into cement, a lux level of around 200 lux may be sufficient.

It is important to note that the lux levels may vary depending on the specific guidelines and regulations of the country and the company. Additionally, factors such as the height and size of the area, reflectivity of surfaces, and the color of the light used can also affect the required lux levels.

To design and calculate lighting effects for your cement plant, please contact us immediately.