Part.1: Why do spray booths use explosion-proof lights?

We all know that paint is a flammable chemical. When the paint reaches a certain concentration in the air, it will burn and explode when it encounters a high temperature open flame. The spray booth is a place where paint does not exist all the time.

The fire hazard of the spray booth is related to the type of paint used, the spray booth method and usage, and the conditions of the spray booth. When flammable paints and organic solvents are used, the danger of explosion and fire is high. Explosion and fire accidents will cause serious loss of life and property, and seriously affect the normal production.

Explosion-proof lamps refer to fixture that take various specific measures to prevent the ignition of surrounding explosive mixtures such as explosive gas environments, explosive dust environments, and gas gases. That is to say, the led explosion-proof lamp is in contact with the explosive gas, there is no possibility of combustion and explosion, and it can play an explosion-proof effect.

Part.2: What are the precautions for the spray booth lighting?

Appropriate illuminance is a very important indicator for the spray booth. Its importance is reflected in: for some workpieces with relatively flat painted surfaces and relatively simple structures, it is acceptable to have a slight lack of illuminance, but for some workpieces with complex structures, if the illuminance of the light source is insufficient, it will be very difficult. It may cause a series of painting problems such as excessively thick, too thin, missing, and flowing paint in some local areas.

Matters needing attention for light source lighting in the spray booth:

First, let’s take a look at the requirements of the spray booth for natural light sources. The light source does not only refer to artificial light sources. If there are natural light sources, natural light sources should be the main ones, but sunlight cannot be directly irradiated on the paint surface. The effect has a greater impact. We can use the baffle to avoid direct sunlight and make the light softer, but it cannot affect the overall lighting, and pay attention to the direction of the light, so that it cannot be easily irradiated to the eyes of the sprayer. Sometimes it is difficult to ensure sufficient light source for natural light. Generally speaking, the area of the window used for lighting should not be less than 20% of the illuminated area.

Second, even if the lighting window is of the right size, it is difficult to ensure sufficient illuminance, because natural light sources are not stable, and in this case, the provision of artificial light sources is essential. When configuring artificial light sources, we must first consider saving, not only to ensure sufficient illuminance, but not to pursue too high illuminance. In order to save the energy consumption of artificial light sources, it is also necessary to control the reflectance inside the spray booth. Generally speaking The reflectivity of the ceiling is generally required to reach more than 85%, and the reflectivity of the wall is generally required to be 60%-70%. Therefore, the ceiling and walls of the spray booth we see are generally white and smooth, and the ground generally requires a reflectivity of 20%. %-30%, this is because the ground has less influence on the illuminance than the ceiling and walls. Generally, the ground of the spray booth is made of non-slip light-colored terrazzo. In addition, for other equipment used for painting, light-colored paint should be used as far as possible on the main color, which is also to maximize the reflectivity.

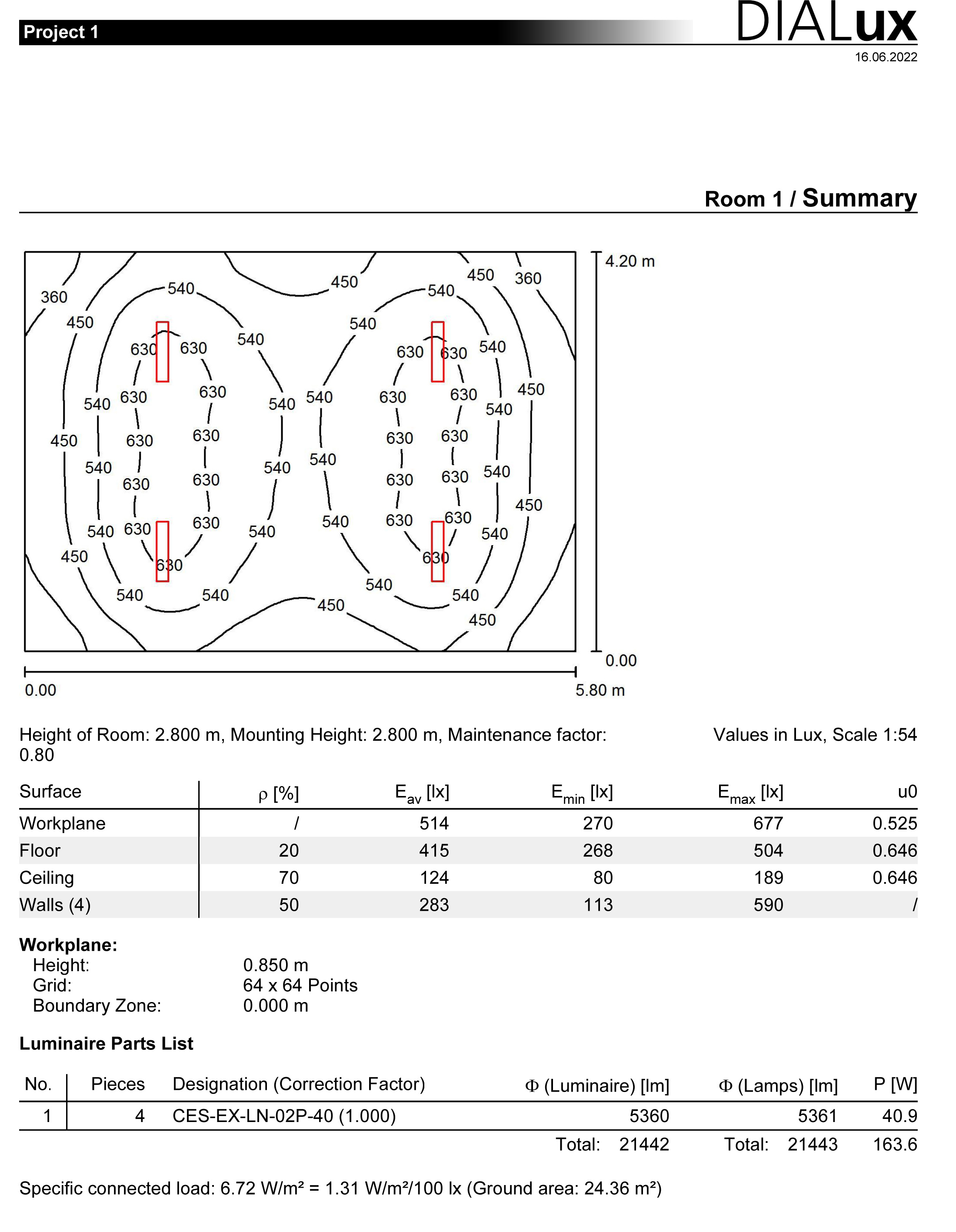

Third, the requirements for the lighting effect of artificial light sources. The artificial light source should be as uniform as possible, and the illuminance should not be less than 500 LUX. If necessary, local artificial lighting can be added separately.

Part.3: How to choose the explosion-proof light of the spray booth correctly?

Explosion-proof lights are widely used in painting room decoration lighting projects, including equipment painting, aluminum alloy doors and windows painting, furniture painting, automobile painting, etc., explosion-proof lights will be used. Therefore, it is very important to choose the right explosion-proof lamps and the right quantity for different spray booths.

What do we need to consider when selecting explosion-proof lamps? The following points are listed below for reference:

- Before purchasing, be sure to check the manufacturer's qualifications of the lamps, including the explosion-proof certificate, confirm that the relevant explosion-proof lamps must meet the national safety regulations and explosion-proof standards, and confirm whether they meet the explosion-proof requirements of the lamps and lanterns in the spray booth.

- Confirm the color rendering index. Now many LED explosion-proof lamps are positive white light, and the color rendering index is only about 80%, and the spray booth requires more than 96%, otherwise the sprayed color will be a little flowery, you are spraying It looks very uniform when you look at it, but it is wrong to look under the natural light outside, so you must pay attention when choosing. Of course, some equipment requirements are not so high, but the requirements for car painting and aluminum alloy doors and windows are relatively high. .

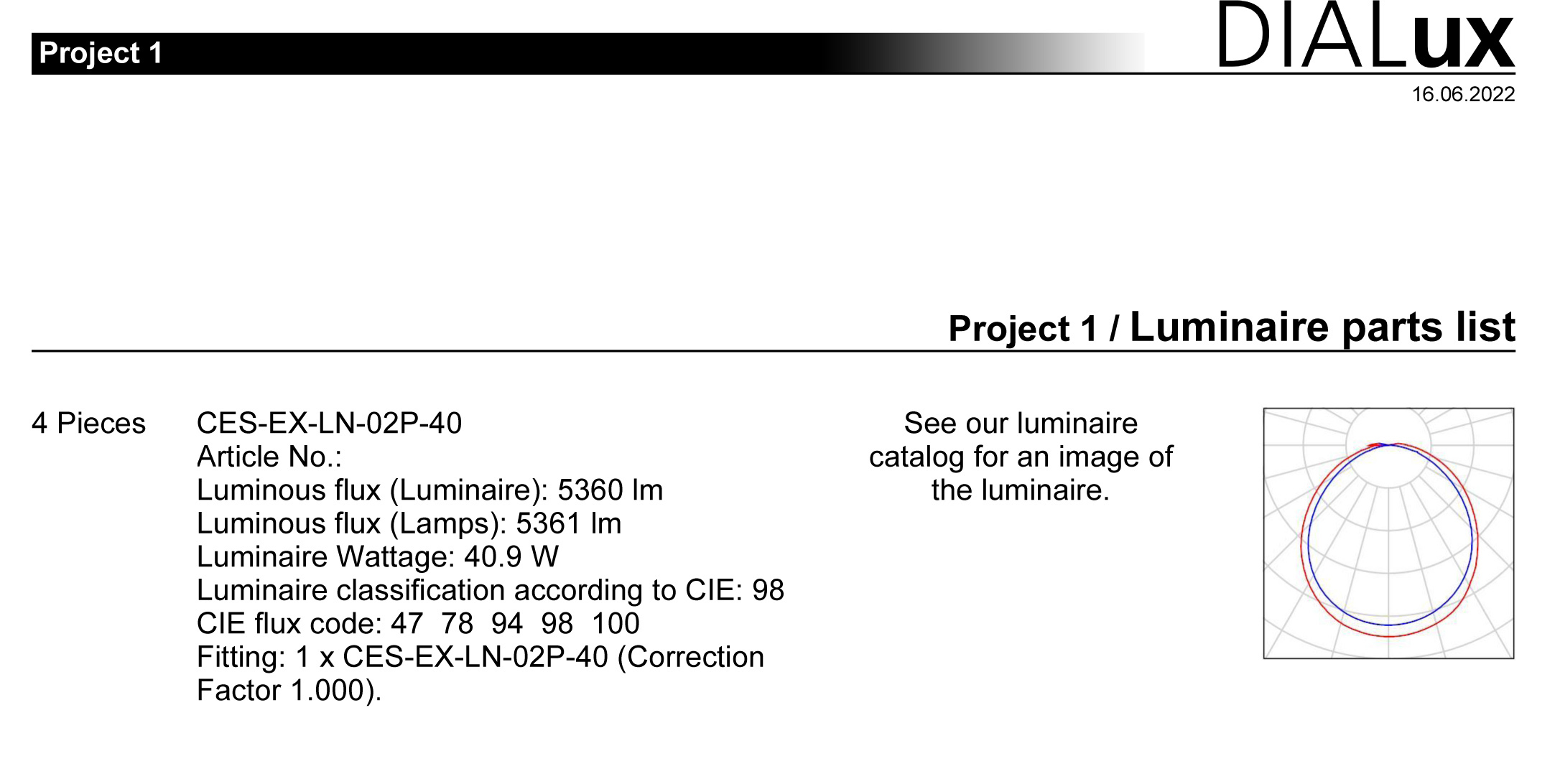

- The brightness requirements must be met, but the Watts should be installed at a generally high distance? How many lamps do you need for the entire room? Compared with traditional lamps, LED lamps are relatively bright. If the spray booth is about 3 meters high, it is probably enough to use 40W LED explosion-proof lamps. However, due to the influence of different lamps and environments, in order to achieve a reasonable lighting result, it is best to perform simulation calculations with lighting design software. (CESP can output Dialux lighting design for you, please tell us the project detailand the length, width and height of the room, send email to This email address is being protected from spambots. You need JavaScript enabled to view it., you can also contact us directlyby whatsapp)

Part.4: What explosion-proof lights are used in furniture spray booths?

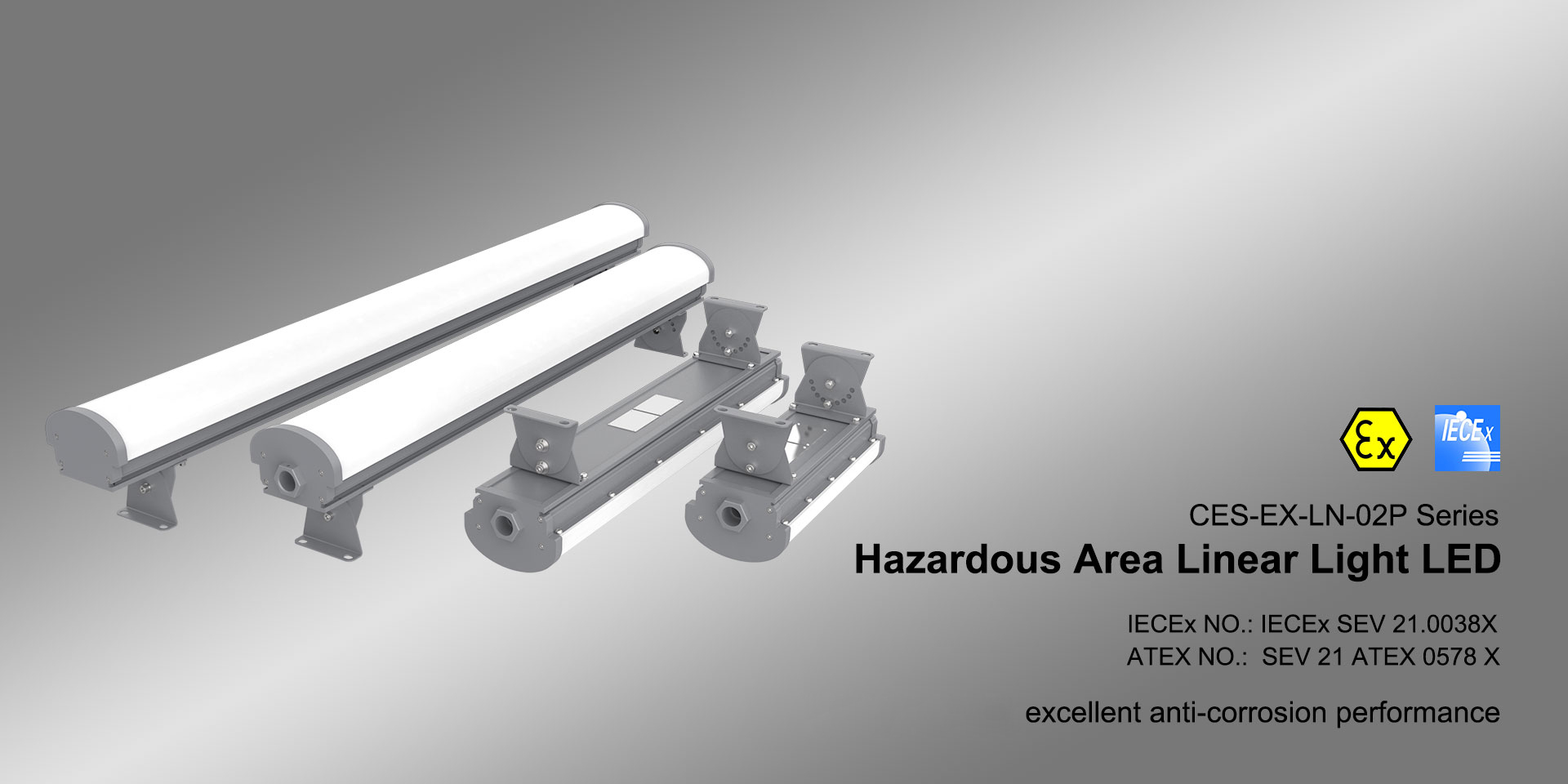

one old customer who has a furniture painting project. The room is roughly 5.8 meters length, 4.2 meters width and 2.8 meters height. The total area of each room is about 20 square meters. How many lights are needed in a room? This customer has purchased several LED explosion-proof lamps from our factory before, most of which are used to replace traditional explosion-proof metal halide lamps and explosion-proof fluorescent lights. Their factory mainly provides lighting fixtures for some oil refineries, boiler flue gas desulfurization projects, and waste-to-energy plants. For the lighting project of furniture painting, we recommended CES-EX-LN-02P series LED explosion-proof floodlights to him. This fixture meets the gas explosion-proof requirements of the painting room, and also meets its lighting brightness requirements.

In addition, a customer in the UK made a request for their car paint booth project:

- The brightness requirements are very high, the illuminance must reach 750 LUX, and it must withstand the test.

- The requirements must be explosion-proof lamps, and can reach Zone 1, IIC level, with ATEX explosion-proof certification and inspection report

- Whether the light will be too dazzling, it is required to change the tempered glass of the lamp to anti-glare glass, so that people will not feel uncomfortable when looking at the light, and they will feel much more relaxed when working.

- It is required that there should be no chromatic aberration, and the wavelength is similar to that of sunlight, so that the sprayed product will not change color. He said that the painter first adjusted the color outdoors, and then used it to spray, so the color temperature of the lamps in the spray booth is generally around 5500K, which is white light.

No matter what kind of spray booth, we will provide a design that meets the lighting requirements according to the customer's application scenario.

If you have any needs, please feel free to contact us. We are happy to offer you a dialux design solution free of charge.