Point. 1 Increase the emphasis on explosion proof distribution panel and control station

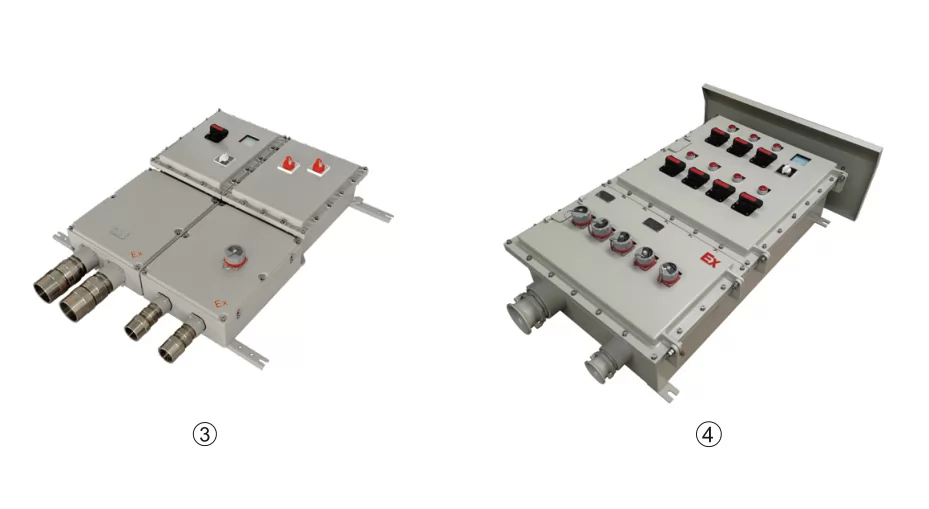

explosion proof distribution panel and control station are generally installed in places with harsh environments. They generally use cast iron casings. Chemical dust can chemically react with the cast iron casings, causing external corrosion or the formation of sticky attachments. Major damage, including mechanical jamming, aging plastic handlebars, corroded bolts, etc.

Explosion proof distribution panel and control station have to be updated in about 5 years. Some maintenance personnel are irresponsible, the explosion-proof end caps are not fixed well, and the terminal board is damaged at will, which will speed up its service life. Among them, the explosion proof distribution panel and control box start from the branch factory, strengthen their supervision and understand their importance. It cannot be regarded as just on-site equipment, which is maintained and managed by the chemical industry. explosion proof distribution panel are maintenance power supplies, not long-term or fixed equipment power supplies. Some maintenance power supplies have been occupied for a long time for water pumps, lighting or small equipment.

Point 2. Explosion proof distribution panel must be numbered uniformly

Many explosion proof distribution panel and control boxes have been uniformly numbered in the power distribution room, but the site number is confusing, and some signs have been dropped. , which greatly affects the maintenance efficiency. It is recommended that the low-voltage section use paint to mark the number at each explosion proof distribution panel and control panel to improve the identification and improve the maintenance efficiency.

Point 3. Adopt one-by-one contracting system

Number each explosion proof distribution panel and control station, and assign the operation section team to contract, and require the operation section on-duty to indicate the integrity of the explosion-proof control box in the work record when overhauling or using the explosion-proof distribution box and control box. And establish a registration book, fill in the registration book for each shift of the duty team, and report the missing bolts or broken end caps in time.

Point 4. Adopt the long-term maintenance system of sharding

The long-term maintenance system for explosion-proof distribution panel and control station is carried out by the team under the jurisdiction of the low-voltage section. Each explosion-proof distribution panel is registered and maintained, and the mechanical parts are maintained every month. Replacement, reinforcement of on-site signs and other related maintenance.

Point 5. Develop a long-term monitoring mechanism

A production period supervision mechanism is established for the explosion-proof control station, and one functional person in the operation section and the low-voltage section is assigned to check and register once a month, and the inspection content includes the identification.

1) Whether the bolts and end covers of explosion-proof distribution panel are in good condition;

2) Whether the explosion-proof distribution panel and control station are marked in the work record;

3) Whether the explosion-proof maintenance power supply is recorded in the contract registration form;

4) Whether the air switch and terminal board in the explosion-proof distribution panel and control station are in good condition; whether the wiring is firm, etc. And according to the relevant situation of the inspection, conduct a reasonable assessment of the operation section team and the low-voltage team.

Point 6. Other measures

1st. Improve the sleeve and hexagon socket tools to reduce the phenomenon that the explosion-proof control station cannot be removed or tightened due to tool defects.

2nd. Treat the bolts of the explosion-proof distribution box and control box, and use the welding and lengthening screws during installation to improve the maintenance efficiency of the operation section.

3rd. Try to use the same spare parts of the same type to reduce maintenance costs and improve maintenance efficiency.