This article mainly explains the global explosion-proof mark and explosion type, including the North American division system explosion-proof mark, Europe and the international zone system explosion-proof mark, it is not only suitable for explosion-proof lamps, but also for other explosion-proof equipment products.

Note: This article is authoritatively published by CESP Explosion-proof Technology Center, for reference only, if you have any contact, please contact us.

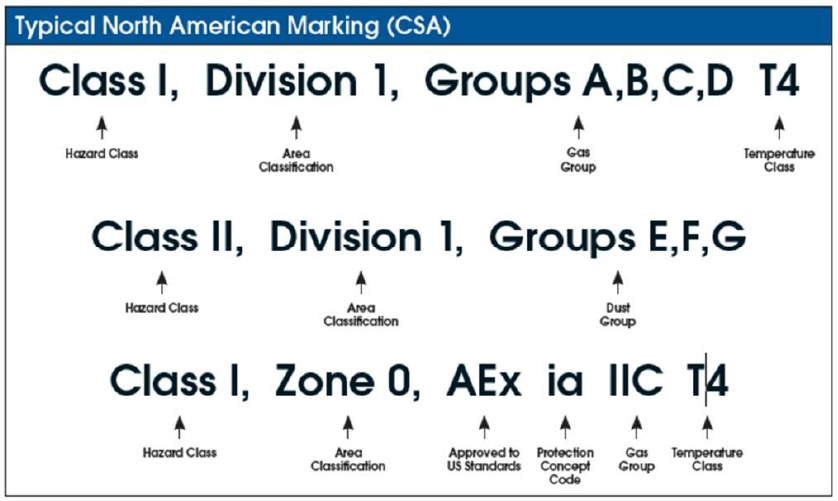

Typical North American Marking (CSA)

Definition of Hazardous Locations - North America

Classification of Regional Explosive classification

|

Class I ·Flammable gas, vaporization or liquid substance Class II ·Combustible dust |

Class I Division/Zone Area

Explosive gas application Location comparison table

|

Division 1 Flammable or explosive substances in a normal environment, or the presence of recurrent |

Zone 0 Flammable or explosive substances in a normal environment for a long time or continuous presence Zone 1 Flammable or explosive substances may be present in a normal environment |

|

Division 2 Flammable or explosive substances are extremely unlikely to exist in a normal environment |

Zone 2 Flammable or explosive substances are extremely unlikely to exist in a normal environment |

Class I Division/Zone

Explosive gas group classification table

|

Division 1 and 2 |

Zone 0, 1 and 2 |

|

A (acetylene) |

IIC (acetylene & hydrogen) |

|

B (Hydrogen) |

|

|

C (Ethylene) |

IIB (Ethylene) |

|

D (propane) |

IIA (propane) |

Class I Division/Zone

Explosive dust group classification table

|

Division 1 and 2 |

Zone 20, 21 and 22 |

|

Metal dust |

IIC (Carbonaceous dust) |

|

F (Carbonaceous dust) |

IIB (Non-conductive dust) |

|

G (Non-conductive dust) |

IIB (Non-conductive dust) |

|

IIA (combustible flyings) |

|

Division |

||

|

Class I Explosive gas |

Group D |

Gas (coal mine) |

|

Group D |

Propane |

|

|

Group C |

Ethylene |

|

|

Group B |

Hydrogen |

|

|

Group A |

Acetylene |

|

|

Class II Explosive dust |

Group E |

Metal Dust |

|

Group F |

Black charcoal /Coal/Coke Dust |

|

|

Group G |

Grain dust |

|

|

Class III flyings |

||

Division System (Class II & Class III Dust)

|

Explosion-proof type |

Mark |

Location |

|

Dust Ignition Proof Dust Protected Pressurisation Pressurisation Intrinsic Safety |

DIP NI PX PY PZ IS |

Class II Division 1 Division 2 Division 1 Division 2 Division 1 |

|

Fiber & Flying Protection |

- |

Class III Division 1 & 2 |

|

International - Zone |

|

|

Group I - Coal mine gas environment |

|

|

Group II Explosive atmospheres other than coal mines |

IIA Propane |

|

IIB Thylene |

|

|

IIC Hydrogen + Acetylene |

|

|

Group III Explosive dust environment other than coal mines |

IIIC Conductive dust |

|

IIIB Non-conductive dust |

|

|

IIIA Flammable flyings |

|

|

North American Zone system |

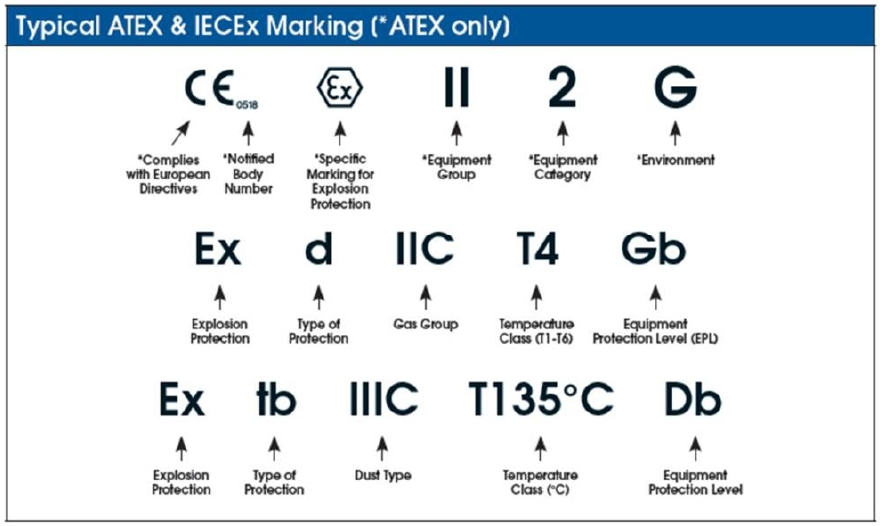

ATEX |

IECEx |

ATEX |

Operating conditions |

|

Ma |

Ma |

Ma |

M1 |

The device still operates when an explosive environment occurs |

|

Mb |

Mb |

Mb |

M2 |

When an explosive environment is present, the device is powered off |

|

Ga |

Ga |

Ga |

1G |

Still running in Zone 0/1/2 |

|

Gb |

Gb |

Gb |

2G |

Still running in Zone 1/2 |

|

Gc |

Gc |

Gc |

3G |

Still running in Zone 2 |

|

Da |

Da |

Da |

1D |

Still running in Zone 0/1/2 |

|

Db |

Db |

Db |

2D |

Still running in Zone 21/22 |

|

Dc |

Dc |

Dc |

3D |

Still running in Zone 22 |

Note: the North American Division system does not have the concept of EPL equipment protection level

Zone System(Gas)

|

Explosion-proof Type |

Mark |

Equipment Protection Level |

|

Intrinsic safety ”i” Encapsulation ”m” |

Ex ia Ex ma |

Ga Ma Ga Ma |

|

Flame Enclosure ”d” Intrinsic safety ”i” Increase safety ”e” Pressurized ”p” Oil immersion ”o” Encapsulation ”m” Power Filling ”q” |

Ex d Ex ib Ex e Ex px Ex py Ex o Ex mb Ex q |

Gb Mb Gb Mb Gb Mb Gb Mb Gb Mb Gb Mb Gb Mb |

|

Intrinsic safety ”i” ”n” Type Encapsulation ”m” |

Ex ic Ex nL Ex nA ExnC Ex nR Ex mc |

Gc Gc Gc |

Zone System(Dust)

|

Explosion-proof Type |

Mark |

Equipment Protection Level |

|

Dust Ignition Protection by Enclosure ”ta” Intrinsic safety ”i” Encapsulation ”m” |

Ex ta Ex ia Ex ma |

Da Da Da |

|

Flameproof Enclosure ”tb” Intrinsic safety ”i” Pressurized Enclosure ”p” Encapsulation ”m” |

Ex tb Ex ib Ex p Ex mb |

Db Db Db Db |

|

Dust Ignition Protection by Enclosure ”tc” Intrinsic Safety ”i” Encapsulation ”m” |

Ex tc Ex ic Ex mc |

Dc Dc Dc |

|

Zone System Group II |

Division System Class I |

Maximum surface temperature / ⁰C |

|

T1 |

T1 |

450 |

|

T2 |

T2 |

300 |

|

T2A |

280 |

|

|

T2B |

260 |

|

|

T2C |

230 |

|

|

T2D |

215 |

|

|

T3 |

T3 |

200 |

|

T3A |

180 |

|

|

T3B |

165 |

|

|

T3C |

160 |

|

|

T4 |

T4 |

135 |

|

T4A |

120 |

|

|

T5 |

T5 |

100 |

|

T6 |

T6 |

85 |

Note: The Max. surface temperature of Zone Group I is 150⁰C or 450⁰C.