Spray Paint Booth is a flammable and explosive environment. The electrical appliances, circuits, and lighting fixtures used must all have electrical regulations of different countries.

Part 1. Common Spray Paint Booth is divided into the following categories

A. Dry Spray Paint Booth

Dry spray paint booths

In each spray booth, the arrangement of the paint mist filter holes will produce a cyclone effect, forcing paint particles to fall on the bottom of the booth, and the airflow will be discharged from the filter, which effectively removes paint mist particles. From this cyclone effect. Depending on the nature of the spray paint product, the filtration rate reaches 96%. Even with the kind of high-performance paint, the surface is rarely blocked. Dry paint mist filter can block every tiny particle.

Features of Dry Paint Booth

- Dry spray booths are the development trend of spray painting operations with low output (limited to working environments with small spray volume)

- The dry spray booth first uses paint mist filter cotton and then uses an activated carbon purifier to filter, and some add a paint mist filter cotton before the activated carbon to extend the life of the activated carbon;

- The simple dry spray booth is very simple to use activated carbon filter;

- The paint mist filter cotton can be reused, and the time is determined by the specific working conditions of the manufacturer;

- Under normal operation, there are no more fire hazards than families;

- The investment is less than that of the wet type, and the operating cost is not high.

B. Water curtain Spray Paint Booth

The characteristic of water curtain Spray Paint Booth is to use the flowing curtain-like water layer to collect and take away the paint mist. The exhaust device ensures that the paint mist does not escape and maintains a good working environment in the workshop. Water curtain Paint Booth is mainly composed of chamber body, tank body, water curtain board, water circulation system, spray system, steam water separation system, slag removal system, exhaust system, etc.

Features of Water curtain Paint Booth as follow,

- Purification efficiency reaches the standard-spray paint mist removal rate ≥90%. The removal rate of hydrophilic dust above 5μm is ≥96%

- Reliable work and operation-safety explosion-proof centrifugal fan is assembled as exhaust device and water circulation power device. Parts that are not prone to failure and frequent maintenance, so the equipment is very reliable.

- Simple operation and maintenance-the basic operation is to start and stop the fan (press a button);

- Convenient and flexible installation-all are modular design, which can be easily combined according to the painting workpiece and process requirements. No special installation foundation and civil construction are required. It is more suitable for the environmental protection equipment installed in the renovation plant.

- Various types of front rooms-suitable front room types and specifications can be selected according to the user's plant conditions and process characteristics.

- No waste water gas discharge-the discharged waste gas is purified by circulating water (special flocculant is added to the water), and the water will evaporate naturally. Therefore, no waste water is discharged. The paint slag remaining in the circulating water can be removed regularly.

- Convenient maintenance in later period-easy maintenance, reliable equipment performance, not easy to malfunction, and easy to use;

- Excellent purification efficiency-due to the air containing paint mist, through the water curtain, water curtain, and the strong mixing and stirring of the water mist in the air-water channel, a multi-stage purification process is formed, which improves the purification efficiency;

- Easy to clean up residues-adding flocculant to the water solves the trouble of paint fog sticking to the equipment, and is easy to clean up to ensure the ventilation effect.

C. Water Spinner Paint Booth

The hydrocyclone type Spray Paint Booth is generally a top-feeding-down exhaust type, and a hydrocyclone structure is used to remove paint mist. It is mainly composed of chamber body, air supply system, paint mist filter system, exhaust system, water circulation system, hydrocyclone, etc. The main principle is: according to the atomization principle of the gas-liquid two-phase mixture, if the speed of water and air is very different, the water can be atomized well in the air, and then fully contact and condense with the paint mist, and finally the water and air The paint is left in the water, and then the water is reprocessed. Water spinner Paint Booth is a large-scale Paint Booth that is currently used more frequently.

Features of Water Spinning Paint Booth as follow,

- The indoor air flow is stable and the paint mist does not scatter.

- Simple structure and quick construction.

- High-efficiency paint mist purification, purification efficiency ≥98%.

- Automatic constant temperature air supply during winter painting

Part 2. The reason why Spray Paint Booth is flammable and explosive

- There is no independent paint spraying room and paint mixing room. Many spray booths generally adopt an open layout, and the surroundings and ceilings are not effectively isolated or closed, and do not meet the national standards for spray booths; some companies have simple job sites, and the paint mixing process is carried out directly in the spray job site. The barrel is left open at will, which is extremely dangerous.

- There is no dedicated hazardous chemical warehouse. Some companies mix paint, thinner, and other items in a warehouse, and some companies even place them directly at the spraying site. Once they encounter an open flame, the fire will spread quickly, with disastrous consequences.

- Insufficient fire separation distance between spray booths. In some companies, the safety distance between the spray booth and the drying operation facility, and the electric welding and gas welding operation site is seriously inadequate.

- The electrical facilities do not meet the requirements. The electrical facilities of many companies' spraying workplaces, such as lighting fixtures, exhaust fans, etc., are general electrical appliances, and no explosion-proof measures have been taken. Temporary wiring, disordered wiring, and the use of ordinary sockets are more common.

- The ventilation effect of the spray booth is poor, and the exhaust air system cannot meet the process safety requirements. During the spraying process, paints and thinners will volatilize a large amount of flammable and explosive mixed gas. The poor ventilation effect directly leads to the accumulation of dust and coating mist, and it is easy to reach the explosion limit of the gas, and encounter sparks generated by open flames or static electricity. , There will be an explosion in an instant.

- On-site management is generally poor. There was a lot of paint waste in the spray booth, and they could not be cleaned up in time.

- The production equipment lacks necessary safety devices and effective measures to eliminate static electricity. Pneumatic spraying operation spray guns and other spraying equipment are not grounded statically, and it is easy to form static electricity accumulation and discharge.

- Insufficient fire-fighting equipment in spraying workplaces and warehouses, and no safety signs and safety cordon lines have been hung.

- The fire-fighting passage in the spraying work site is not smooth. The overall layout of the spraying workplace is unreasonable, and raw materials, semi-finished products, finished products and other materials are stacked at will, causing serious blockage of the fire-fighting passage.

- Anti-static work clothes, protective glasses, conductive shoes and other protective products are not equipped in accordance with the specifications or used correctly during spraying operations.

- Business owners don't pay enough attention to safety production, lack of specialized safety production management personnel, safety production rules and regulations are not sound, enterprise safety production investment is insufficient, and safety investment is too much in debt.

- Business owners and practitioners lack the proper understanding and understanding of the dangers of paints, coatings, and thinners used in spraying operations.

Part 3. Spray Paint Booth lighting requirements

For Paint Booth, the appropriate light source illuminance is a very important indicator. Its importance is reflected in the fact that for some workpieces with a relatively flat painted surface and a relatively simple structure, a slight lack of illuminance is acceptable, but for some workpieces with complex structures, it is very important if the illuminance of the light source is insufficient. It may cause a series of painting problems such as excessive thickness, thinness, leakage, flow, etc. in some parts of the spray paint. At this time, it is necessary to use special lamps for hazardous locations.

Illumination: The brightness of Paint Booth needs to reach 800-1000lux, and it needs to be close to D65.

At the same time, the inner wall of Paint Booth should be matte white. When using partitions made of transparent materials such as glass for lighting, fixed luminaires should be used as light sources, and partitions should be used to separate the area where the luminaires are installed from the electrostatic paint area. The installation gaps should be reliably sealed. The material of the partitions is It is non-flammable and not easy to break, and the thickness of the deposit on the partition shall not affect the specified illuminance.

Enclosed explosion-proof is required: Paint is a flammable chemical. When the paint reaches a certain concentration in the air, it will burn and explode when it encounters a high-temperature open flame. And Paint Booth is a place where paint does not exist all the time, and explosion proof led lights can meet this point of explosion and safety.

The fire hazard of the Paint Booth workshop is related to the type of paint used, the method and amount of Paint Booth used, and the conditions of the Paint Booth site. When flammable coatings and organic solvents are used, there is a greater risk of explosion and fire. Explosion and fire accidents will cause serious loss of life and property, and seriously affect the normal production of production.

Paint Booth lighting fixtures should be powered by explosion-proof lamps in hazardous areas, and the grade must be at least IIC explosion-proof: safe, explosion-proof, and energy-saving. The standard lighting voltage is AC 220V. According to special engineering needs, AC 127V or DC 36V may be used.

Part 4. CESP Explosion proof LED Lights for Spray Paint Booth

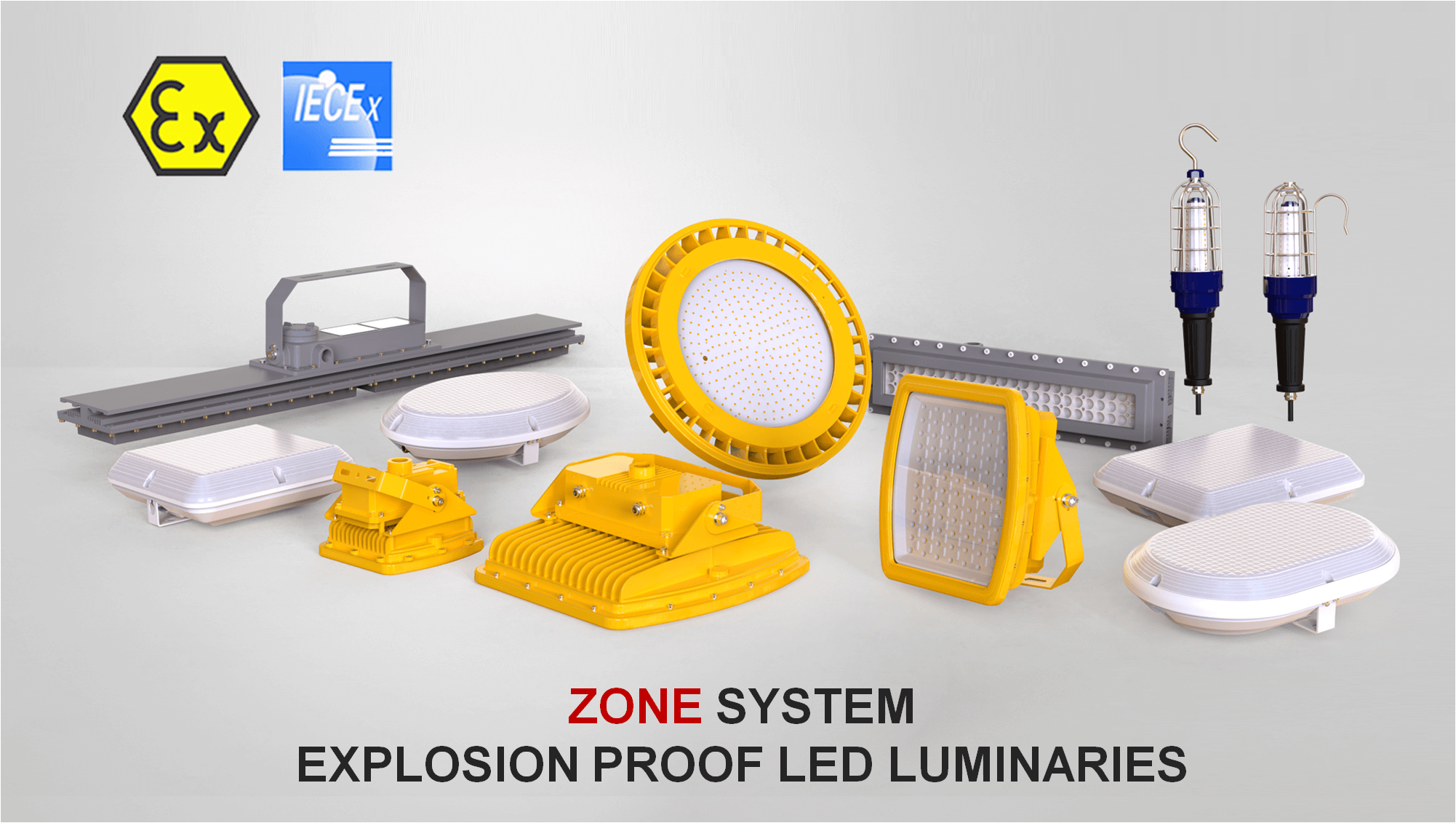

CESP LED explosion-proof lights have all obtained North American explosion-proof certification. Class I Division 2 LED explosion-proof lights and IECEx, ATEX Zone1 LED Lights are suitable for Spray Paint Booth Lighting.

CES-EX-LN-02P Series is more cost-efficient as the spray paint booth light, if you need a detailed lighting solution, please provide paint booth drawings, or the Booth Dimension. Our R&D department will provide professional lighting solutions for you.

Tab.: Spray Paint Booth Light, Paint Booth Lighting, Paint Spray Booth Lighting, Paint Booth LED Light Fixtures