Do you know what’s the notice in gas boiler explosion-proof lighting and other Explosion-proof equipment design?

With the increasing efforts of national environmental pollution control and energy structure adjustment, the proportion of gas boiler houses is increasing in the construction of boiler houses.

With the increasing efforts of national environmental pollution control and energy structure adjustment, the proportion of gas boiler houses is increasing in the construction of boiler houses. The gas boiler room uses natural gas as fuel, and natural gas is a flammable and explosive gas. Therefore, the design of the gas boiler room pays special attention to safety issues. The electrical equipment in the boiler room is mostly equipped with explosion-proof.

Over time, people can easily form a fixed thinking, the boiler room belongs to the hazardous areas, and should be designed according to explosion proof standard.

Actually, this is a misunderstanding in our judgment.

We cannot simply determine that this area is an hazardous area because of the existence of flammable and explosive gases in a certain area. Instead, it should be considered in combination with the process production process and fire risk classification of the area. If the area is indeed an explosion hazardous area, the area of the explosive gas environment should be classified according to the provisions of the “Explosion Regulations” and the range of the area should be determined. Then, according to the type of the hazardous area of the explosive gas environment, corresponding explosion-proof design measures should be taken, such as "Explosion Hazardous Environment Power Device Design Specification", and different country have different standard and requirement.

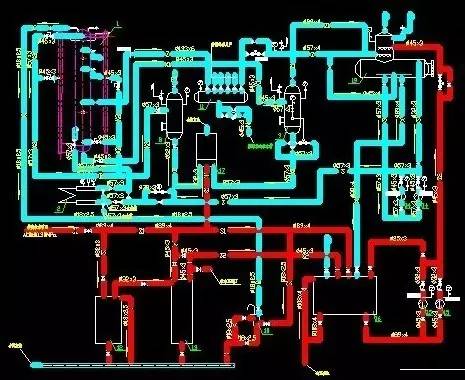

Electrical design and electrical equipment selection for gas boilers

The boiler body in the boiler room, the electric control box of the boiler, and the electrical instruments on the boiler are all common equipment, not explosion-proof electrical equipment. There is no any sense to require only the electrical professional to use explosion-proof electrical equipment. For example, GB 50041 - 2008 "Boiler House Design Code" does not stipulate that the electrical profession must be designed in accordance with the requirements of explosion protection. It just asks for electrical design are as follows:

The choice of motor, start-up control equipment, luminaires and conductor types should be compatible with the environmental classification of the different buildings and structures in the boiler room.

The classification of explosion and fire hazard sites in boilers, gas pressure control rooms, fuel pump rooms, pulverized coal preparation rooms, coal crushers rooms and coal transportation corridors of fuel and gas boiler rooms must comply with the national standards. Relevant provisions for environmental power device design specifications.

The provisions are as follows,

In the gas, if the main component of natural gas is methane, it is easy to catch fire when it forms a mixed gas with 5% to 15% concentration of air. Therefore, the natural gas pressure regulating room belongs to explosion-proof buildings... Buildings and structures in different environments The selected motor and electrical equipment should be compatible with the different environments.

It can be seen that the selection of electrical equipment is compatible with the environmental classification of buildings and structures, and the selection requirements for electrical equipment in Class A and Ding production plants are quite different.

The determination of the explosion hazardous area in the production plant shall not deviate from the process characteristics and production process, and shall not deviate from the qualitative nature of the building. If these factors are not taken into account, the room shall be declared explosive according to the provisions of the "Explosion Regulations". the design of electric power in an explosive gas environment is a joke.

For example, the kitchen using natural gas and liquefied gas is in full compliance with the "explosion regulations", but no one will be electrically designed according to the explosive gas environment, nor will the kitchen appliances be used for explosion-proof products. The gas design code has clearly pointed out that the boiler room and the water heater room are non-explosive hazardous places, so it is not unreasonable to select electrical equipment according to the normal environment.

When carrying out the electrical design of the gas boiler room, the boiler room should be classified according to the production characteristics and production process of each room, combined with the fire hazard level of the plant to determine which rooms belong to the hazardous areas of explosion, and then according to the provisions of the “Explosion Regulations”. Partition the hazardous area and determine the extent of the partition, then take appropriate explosion-proof design measures.

For example, in the gas inlet room, it is a Class A production room and belongs to Zone 2 of the explosive gas hazardous environment. Equipment selection should be carried out according to the requirements of Zone 2. The boiler room is a Ding production room, which is not an explosion hazardous area and can be electrically designed according to the normal environment. Generally speaking, when a valve appears in a gas boiler room, the valve is equivalent to a release source, and the explosion source is within a certain range of the release source within a certain range, and electrical equipment should be avoided in the area.

However, in most cases, the valves are placed close to the boiler body. The actual design of the boiler body, boiler electrical control box, and electrical instruments on the boiler are common equipment, and many gas design standards also indicate These places in the boiler room and the water heater room are non-explosive hazardous areas, which is also the reason why the boiler room is characterized as a D-type production room. If it is considered that the entire boiler room is an explosion hazardous area and is designated as an explosive gas environment zone 2, it is inconsistent with the regulations on the risk of fire in the boiler room.

Other safety measures for electrical design of gas boilers

As mentioned earlier, there is no basis for setting the boiler room as an explosion hazard area.

Of course, in order to ensure the operation and maintenance safety of the boiler, we must take some safety measures, such as setting the flammable gas concentration alarm device, accident exhaust device, and pipeline for anti-static grounding. In some administrative regulations, explosion-proof luminaires are required in the boiler room. These additional requirements should also be followed by the designer. This is equivalent to raising the design standards (although there is no substantial effect on safety) and the explosion between the boiler and the boiler. The explosion protection measures that must be taken in the area are two distinct concepts.

In addition, the accidental fan of the gas boiler room must be explosion-proof. This is reasonable and necessary, because the accident fan is not characterized according to its installation area, but is characterized according to the nature of its work. It is an accident in which the concentration of flammable gas exceeds the standard. In order to work, an explosion-proof motor must be used to ensure safety. Even if the accident fan is placed in the open environment of the roof, an explosion-proof fan is still required.

From the controversy over the electrical design of the gas boiler room, it is clear that people attaches great importance to the safety of gas use, which is a good thing. However, it is not enough to pay attention to it. It is also necessary to understand the dangerous factors of gas in various environments.

For example, the danger of the gas boiler house during the outage period is often higher than during the operation period. During the shutdown of the boiler, the residual gas in the furnace will pose a safety hazard. Therefore, the furnace must be cleaned with compressed air before the furnace is repaired. In order to carry out open fire operations. Of course, the safety of boiler maintenance has a strict set of operating procedures, which is no longer within the scope of electrical design.

At present, some electrical designers who have met the gas pipeline, regardless of the location, and whether the valve is installed on the gas pipeline, will set the flammable gas concentration alarm device, and the electrical equipment will be changed to explosion-proof type, which will waste money and fail to play. Any security role.

Question about location classification

Not only the gas boiler room, but also the electrical design of other explosive gas environments, it is necessary to combine the process characteristics and production process to classify the site reasonably, and determine the explosion danger zone, the explosive gas environment zone and the zone range. This is a highly specialized and complex job that is closely related to process equipment layout, production processes, raw material/product storage, physical and chemical properties of hazardous releases, and ventilation conditions.

The work of site classification is far from being as simple as some people think, and electrical engineers are not qualified for this job. Each country has a certified safety engineer with comprehensive expertise in process, ventilation, and electrical related fields. The classification of the site, the zoning of the explosive gas environment, and the scope determination are the responsibility of them.

Summary as follow

a. The gas boiler room is not an explosion hazardous area.

b. The boiler body, boiler electric control box and electrical instrument on the boiler in the gas boiler room are common equipment, not explosion-proof electrical equipment. The electrical professional can design and select according to non-explosive hazardous areas.

c. Some places have administrative regulations that require explosion-proof electrical appliances in gas-fired boiler rooms. Electrical design can improve design standards according to this requirement.

d. Accident fans in gas boiler rooms should use explosion-proof motors.

e. If there is no valve on the gas line, it is not necessary to perform electrical design in the hazardous areas where it is exposed.

f. The classification of the explosive gas environment require comprehensive technical expertise in the relevant fields such as process, ventilation and electrical. This work is generally performed by professionals.

CESP provide all kinds of LED explosion proof lighting fixtures for hazardous areas, including gas boiler plant lighting fixture, contact us to ask detail and professional lighting solution for your projects.